Ecoboost condensate catch can, post your results here

#61

Thanks Pack - fair enough.

Tuner - I think the Rx can (or the other catch cans as you have also mentioned) stands on its merit of usefulness. That said, would it be easy to set up an experiment? You could have a truck that has known deposit issues, fully clean it and install the Rx system. Equally, you could have a truck with the same issue do the cleaning and drill a weep hole. While you would not know what is evacuated through a "catch" you could verify the interior of the system by visual inspection to look for evidence of stuff.

Im interested to see the relative results over the change of seasons - we have pronounced seasons in Philly. I'd say I will post the results, but I know me and this is one thing I probably will not get to - so might as well be transparent. lol.

Tuner - I think the Rx can (or the other catch cans as you have also mentioned) stands on its merit of usefulness. That said, would it be easy to set up an experiment? You could have a truck that has known deposit issues, fully clean it and install the Rx system. Equally, you could have a truck with the same issue do the cleaning and drill a weep hole. While you would not know what is evacuated through a "catch" you could verify the interior of the system by visual inspection to look for evidence of stuff.

Im interested to see the relative results over the change of seasons - we have pronounced seasons in Philly. I'd say I will post the results, but I know me and this is one thing I probably will not get to - so might as well be transparent. lol.

We have over 200 systems installed now and every one that has given feedback (and many were not concerned about the water in the CAC as they had done the weep hole with success, they were seeking a solution for the oil being diluted so much with gasoline and water, and the system has cured that in every single one) claims the issues have gone away. But yes, any test anyone wants to do will show the same. Let me know what you plan to do and how I can help.

And here is another test anyone can do....delete the PCV system from a 5.0 or other NA engine that does not experience this and the same thing happens.

These compounds must be evacuated (removed) as soon as they enter the crankcase before they can accumulate. So since the EB only evacuates during idle and low throttle when no boost is present, 80% plus of the time there is no evacuation taking place. Evacuation must have a fresh air source on one bank, and a exit for the foul vapors on the opposite and this flow must always be maintained in the fresh in drivers side, foul out passenger side to accomplish evacuation as this video shows:

And the Volvo Turbo PCV system is always under vacuum and this video demonstrates how it is properly designed and pulls vacuum at all times (the narrator says pressure, which is an error. Vacuum shows good on this device, pressure shows bad. You MUST always have vacuum to operate properly. Try this on an EB and as soon as you have ANY boost you cease evacuation, and then pressure builds seeking the path of least resistance, which is to push all the accumulated steam/vapors of water/fuel/sulfuric acid and oil mist into the driver side intake tube where it is then pushed into the CAN and condenses in addition to the oil becoming full of this as well:

Want to do more test yourself? Remove the oil cap, and with the engine at idle, place your hand over the oil fill hole and feel the vacuum (evacuation is present). Now with someone in the drivers seat have them very firmly hold the brakes and in gear bring throttle up and the turbos will spool and build boost (do NOT stand in front of the vehicle) now you feel pressure push on your hand...no evacuation is taking place. The Vovo turbo has no issues with CAC water accumulation UNLESS the system is clogged and causes the same thing to occur that the EB does standard. Ford has very little past experience with turbo charging production vehicles, but has done PD blowers since the Lightning, and there the blower is always creating suction so it has never had to deal with this before. Volvo has been turbo charging for ages and has the system designed correctly. Look at the GM Caddy 2.0 turbo....see how they use the suction from the turbo inlet to evacuate?:

They only evacuate in boost, so they have the same issue, just not as severe. We correct that system by taping into the intake manifold vacuum for evacuation at idle and low throttle....it is that simple, we just use the principal from each together (like the Volvo does) to accomplish constant and steady evacuation so this mix can never accumulate:

See. none of this is new, just the ecoboost system but we have been doing the same thing for over 12 years and over 14,000 systems in use, and to date we are the only one doing this even though we show other how to accomplish the same. So the results wont magically change in the summer....proper crankcase evacuation has been critical for ages, and the problems that occur when it is not designed properly, or has an issue (clogged, hose broken, etc.) have also been the same so none of this is new.

Here is another by Matt Scranton, local to us and have raced with him for years. Also, Aerospace Components is one of our sponsors of our race team and we have run their pumps for years:

Crankcase pressure is NEVER good, and although this is showing power gains, vacuum is always critical for an engine to perform properly and to evacuate the crankcase of the damaging compounds the EB crowd has just recently begun to experience.

So lets discuss more. this is all good but we first must understand the critical importance of PCV systems and how they evacuate the crankcase, what they are evacuating, and what happens when this is allowed to accumulate when a PCV system is flawed, clogged, or non-functioning

The following users liked this post:

STANSUSKI (04-08-2014)

#62

Here is a very technical white paper by a engineer in the UK that covers most every aspect from the most basic to the most advanced, and all the mathematical formulas one could want. Also, I should point out that the RX system is a true separator, and not a "catchcan" as 99% on the market are. It is just the common name given to any device used to trap oil and other compounds. This is covered in this paper as well.

Please excuse the terminology used, you have to translate "British English" to American English.:

http://www.106rallye.co.uk/members/d...hersystems.pdf

http://www.106rallye.co.uk/members/d...hersystems.pdf

Please excuse the terminology used, you have to translate "British English" to American English.:

http://www.106rallye.co.uk/members/d...hersystems.pdf

http://www.106rallye.co.uk/members/d...hersystems.pdf

#63

So, and bear in mind I am far more clueless on PCV systems and I apologize, but I am not going to read the papers, does this mean with the RX system, after install, there will be no yellow sludge present in the bottom of the CAC?

Before I drilled, baby drilled - both the weep hole and for the Rx system - there was a yellow sludge in my CAC. Since I have the weep hole, I can't do this test. BUT I have to believe there is someone that has the sludge and no weep hole... It would be great to have them install the Rx system and inspect the CAC after 5K or so miles to see if the sludge is no more.... As least part of the theory will be proven right here within the community.

I'll call you regarding another issue, but want to put it out there to see if anyone else has this going on: The hose that is connected to the intake pipes pre-turbo is "crushing/pinching" just aft the can connection (left most). Is this happening to others? Is this normal?

Before I drilled, baby drilled - both the weep hole and for the Rx system - there was a yellow sludge in my CAC. Since I have the weep hole, I can't do this test. BUT I have to believe there is someone that has the sludge and no weep hole... It would be great to have them install the Rx system and inspect the CAC after 5K or so miles to see if the sludge is no more.... As least part of the theory will be proven right here within the community.

I'll call you regarding another issue, but want to put it out there to see if anyone else has this going on: The hose that is connected to the intake pipes pre-turbo is "crushing/pinching" just aft the can connection (left most). Is this happening to others? Is this normal?

#64

And for real pricey solutions Racor does it well:

http://www.parker.com/literature/Rac...0Brochure).pdf

At the bottom they show the importance of a proper vapor separated system for a turbo application that uses both suction sources so flow is always correct.

But the nay-sayers will argue that the SAE (society of automotive engineers), and the engineers referenced here, and companies such as Racor and Alfa laval know nothing as well as they go off on tangents that have nothing to do with proper crankcase evacuation.

I can go on and on with the engineering and scientific data but if this does not cover any doubt I don't know what can.

Again, I AM an automotive engineer, have had my designs used my the Big 3, and have done this my entire adult life (over 40 years), and forced induction and crankcase evacuation is my specialty. I am quoted in industry publications, Performance magazines and other related media for ages on these subjects....yet it always seems to come down to a few keyboard experts somehow know so much more than all of this.

http://www.parker.com/literature/Rac...0Brochure).pdf

At the bottom they show the importance of a proper vapor separated system for a turbo application that uses both suction sources so flow is always correct.

But the nay-sayers will argue that the SAE (society of automotive engineers), and the engineers referenced here, and companies such as Racor and Alfa laval know nothing as well as they go off on tangents that have nothing to do with proper crankcase evacuation.

I can go on and on with the engineering and scientific data but if this does not cover any doubt I don't know what can.

Again, I AM an automotive engineer, have had my designs used my the Big 3, and have done this my entire adult life (over 40 years), and forced induction and crankcase evacuation is my specialty. I am quoted in industry publications, Performance magazines and other related media for ages on these subjects....yet it always seems to come down to a few keyboard experts somehow know so much more than all of this.

#65

So, and bear in mind I am far more clueless on PCV systems and I apologize, but I am not going to read the papers, does this mean with the RX system, after install, there will be no yellow sludge present in the bottom of the CAC?

Before I drilled, baby drilled - both the weep hole and for the Rx system - there was a yellow sludge in my CAC. Since I have the weep hole, I can't do this test. BUT I have to believe there is someone that has the sludge and no weep hole... It would be great to have them install the Rx system and inspect the CAC after 5K or so miles to see if the sludge is no more.... As least part of the theory will be proven right here within the community.

I'll call you regarding another issue, but want to put it out there to see if anyone else has this going on: The hose that is connected to the intake pipes pre-turbo is "crushing/pinching" just aft the can connection (left most). Is this happening to others? Is this normal?

Before I drilled, baby drilled - both the weep hole and for the Rx system - there was a yellow sludge in my CAC. Since I have the weep hole, I can't do this test. BUT I have to believe there is someone that has the sludge and no weep hole... It would be great to have them install the Rx system and inspect the CAC after 5K or so miles to see if the sludge is no more.... As least part of the theory will be proven right here within the community.

I'll call you regarding another issue, but want to put it out there to see if anyone else has this going on: The hose that is connected to the intake pipes pre-turbo is "crushing/pinching" just aft the can connection (left most). Is this happening to others? Is this normal?

And on the kinked hose, you dont want that.

Last edited by Tuner Boost; 03-15-2014 at 04:02 PM.

#67

And for real pricey solutions Racor does it well:

http://www.parker.com/literature/Rac...0Brochure).pdf

At the bottom they show the importance of a proper vapor separated system for a turbo application that uses both suction sources so flow is always correct.

But the nay-sayers will argue that the SAE (society of automotive engineers), and the engineers referenced here, and companies such as Racor and Alfa laval know nothing as well as they go off on tangents that have nothing to do with proper crankcase evacuation.

I can go on and on with the engineering and scientific data but if this does not cover any doubt I don't know what can.

Again, I AM an automotive engineer, have had my designs used my the Big 3, and have done this my entire adult life (over 40 years), and forced induction and crankcase evacuation is my specialty. I am quoted in industry publications, Performance magazines and other related media for ages on these subjects....yet it always seems to come down to a few keyboard experts somehow know so much more than all of this.

http://www.parker.com/literature/Rac...0Brochure).pdf

At the bottom they show the importance of a proper vapor separated system for a turbo application that uses both suction sources so flow is always correct.

But the nay-sayers will argue that the SAE (society of automotive engineers), and the engineers referenced here, and companies such as Racor and Alfa laval know nothing as well as they go off on tangents that have nothing to do with proper crankcase evacuation.

I can go on and on with the engineering and scientific data but if this does not cover any doubt I don't know what can.

Again, I AM an automotive engineer, have had my designs used my the Big 3, and have done this my entire adult life (over 40 years), and forced induction and crankcase evacuation is my specialty. I am quoted in industry publications, Performance magazines and other related media for ages on these subjects....yet it always seems to come down to a few keyboard experts somehow know so much more than all of this.

But I too bow out of these threads. Nothing new is to be learned here.

I simply disagree with the tiny bit of your explanation relating to the impossibility of condensation forming from atmospheric moisture. And that will not change until more data is available so further debate is pointless.

I think you have a very strong case regarding oil contamination with gas and with the reports of timing chain problems related to the PCV system. Stick to that part of the story and I certainly will not disagree.

#68

I review technical papers as part of the peer review process for publication in scientific journals on a daily basis. These are all submitted by experts in their fields. In every one, a major error is caught by reviewers that needs to be corrected. We all have out blind spots. Especially the experts.

But I too bow out of these threads. Nothing new is to be learned here.

I simply disagree with the tiny bit of your explanation relating to the impossibility of condensation forming from atmospheric moisture. And that will not change until more data is available so further debate is pointless.

I think you have a very strong case regarding oil contamination with gas and with the reports of timing chain problems related to the PCV system. Stick to that part of the story and I certainly will not disagree.

But I too bow out of these threads. Nothing new is to be learned here.

I simply disagree with the tiny bit of your explanation relating to the impossibility of condensation forming from atmospheric moisture. And that will not change until more data is available so further debate is pointless.

I think you have a very strong case regarding oil contamination with gas and with the reports of timing chain problems related to the PCV system. Stick to that part of the story and I certainly will not disagree.

Here are some examples of the RX systems over the years:

GM full size V8 trucks & SUV's:

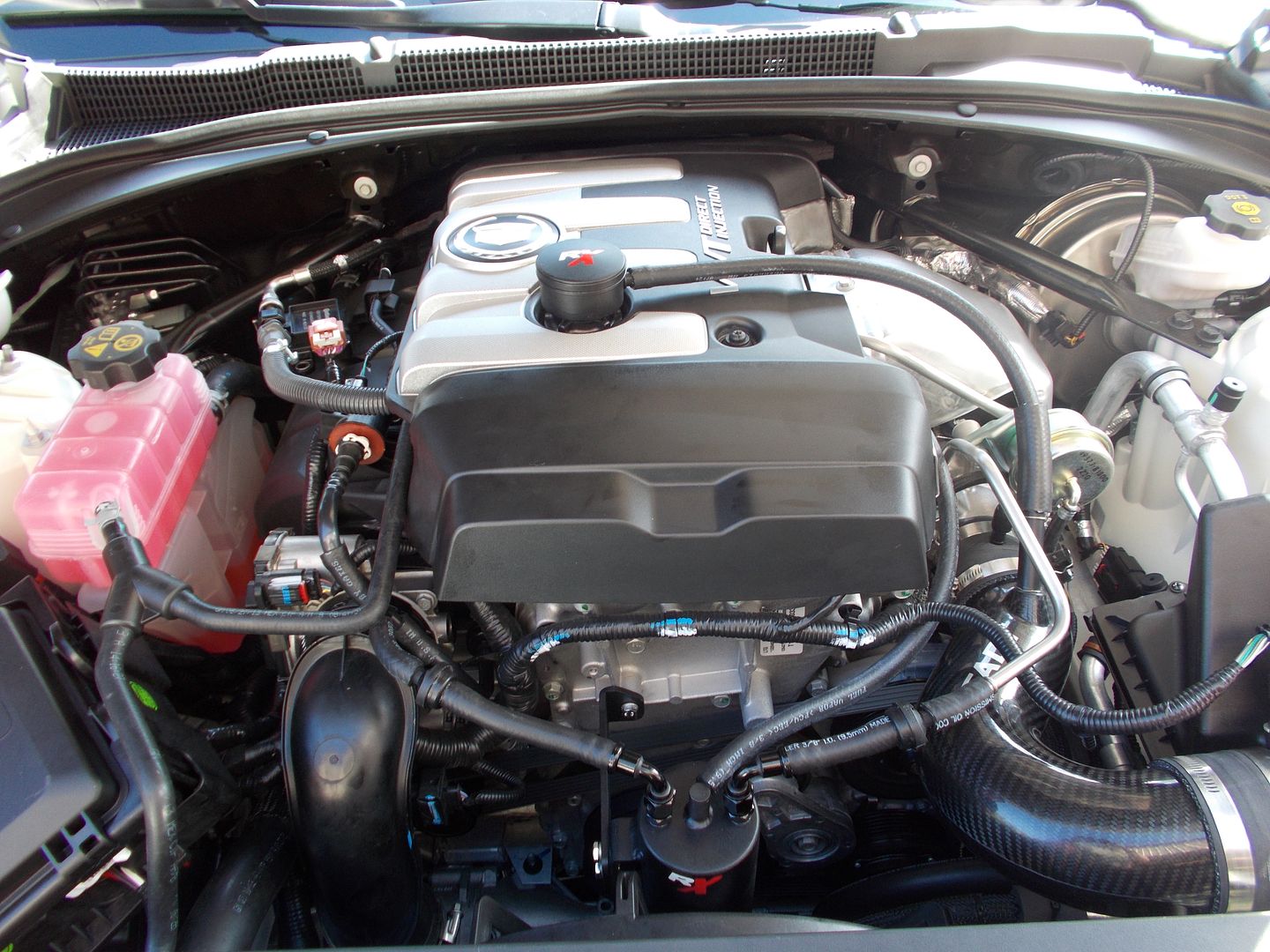

Current GM mid sized SUV V6 DI (Caddy SRX/GMC Acadia/Chev Traverse):

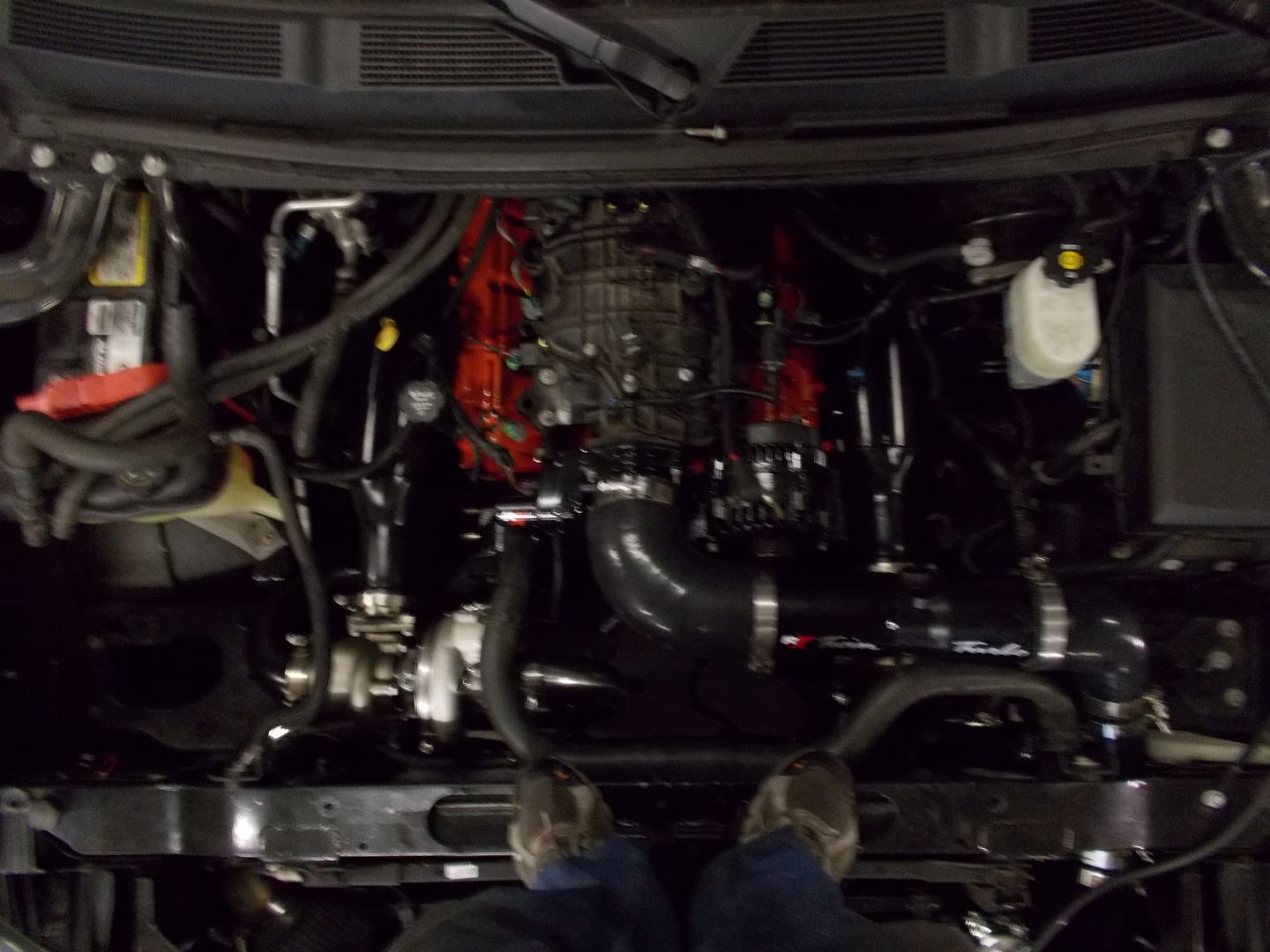

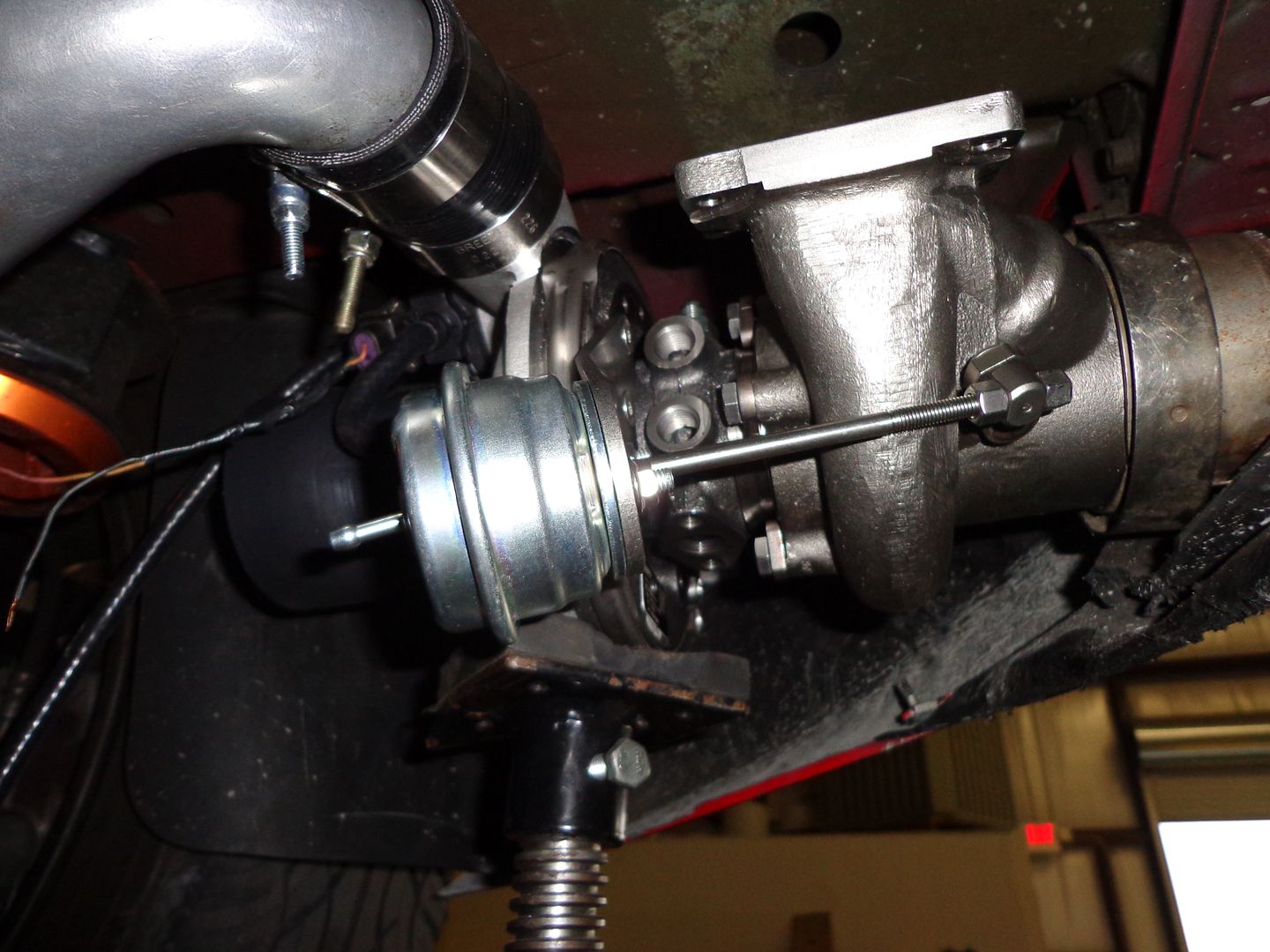

Current GM Camaro V6 and Caddilac CTS V6 DI: Single turbo

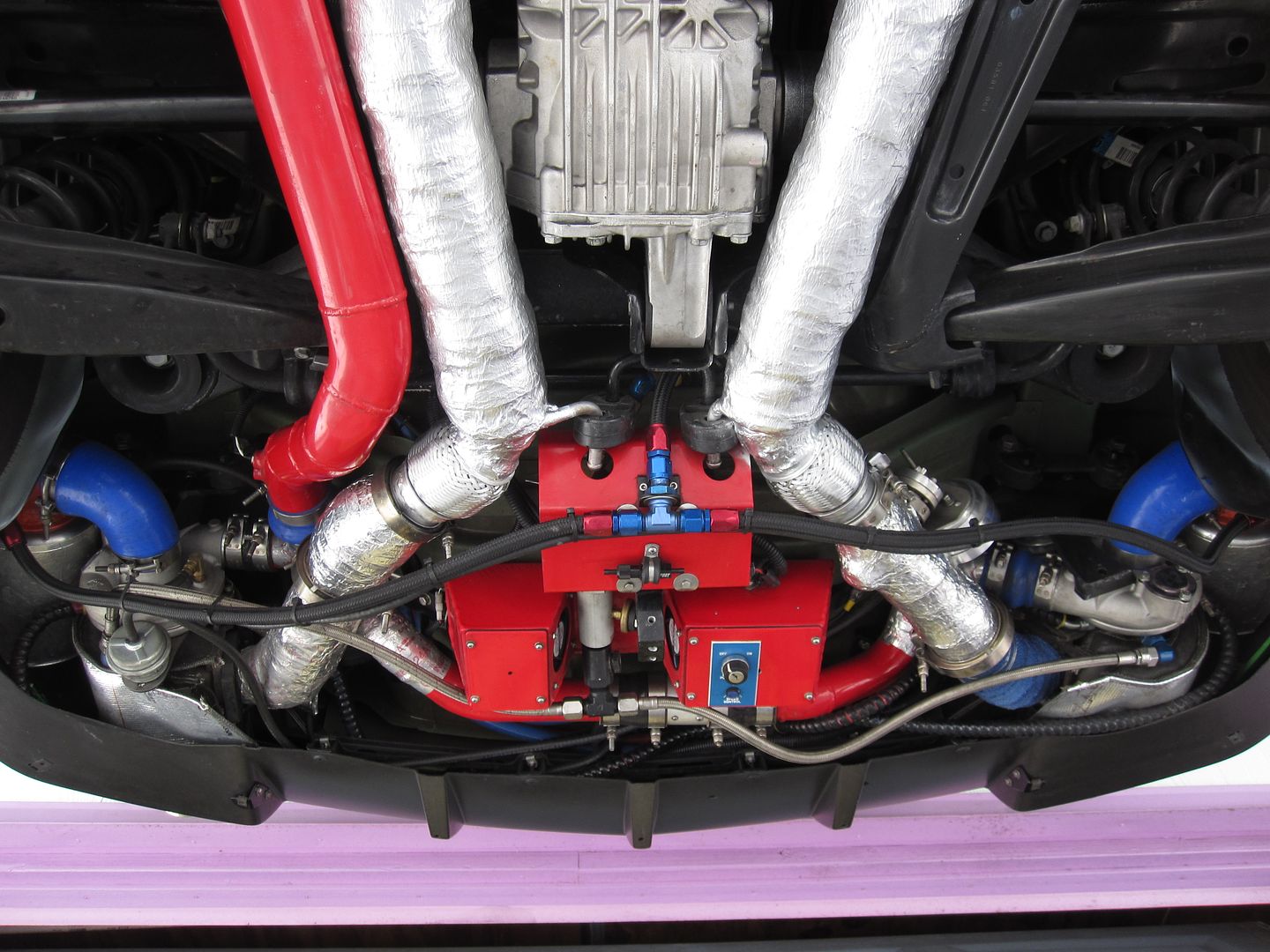

And twins:

Rear mount systems for most makes:

Single systems for GM V8's:

First and only top mount PD blower for the Gen5 Camaro V6 DI:

#70

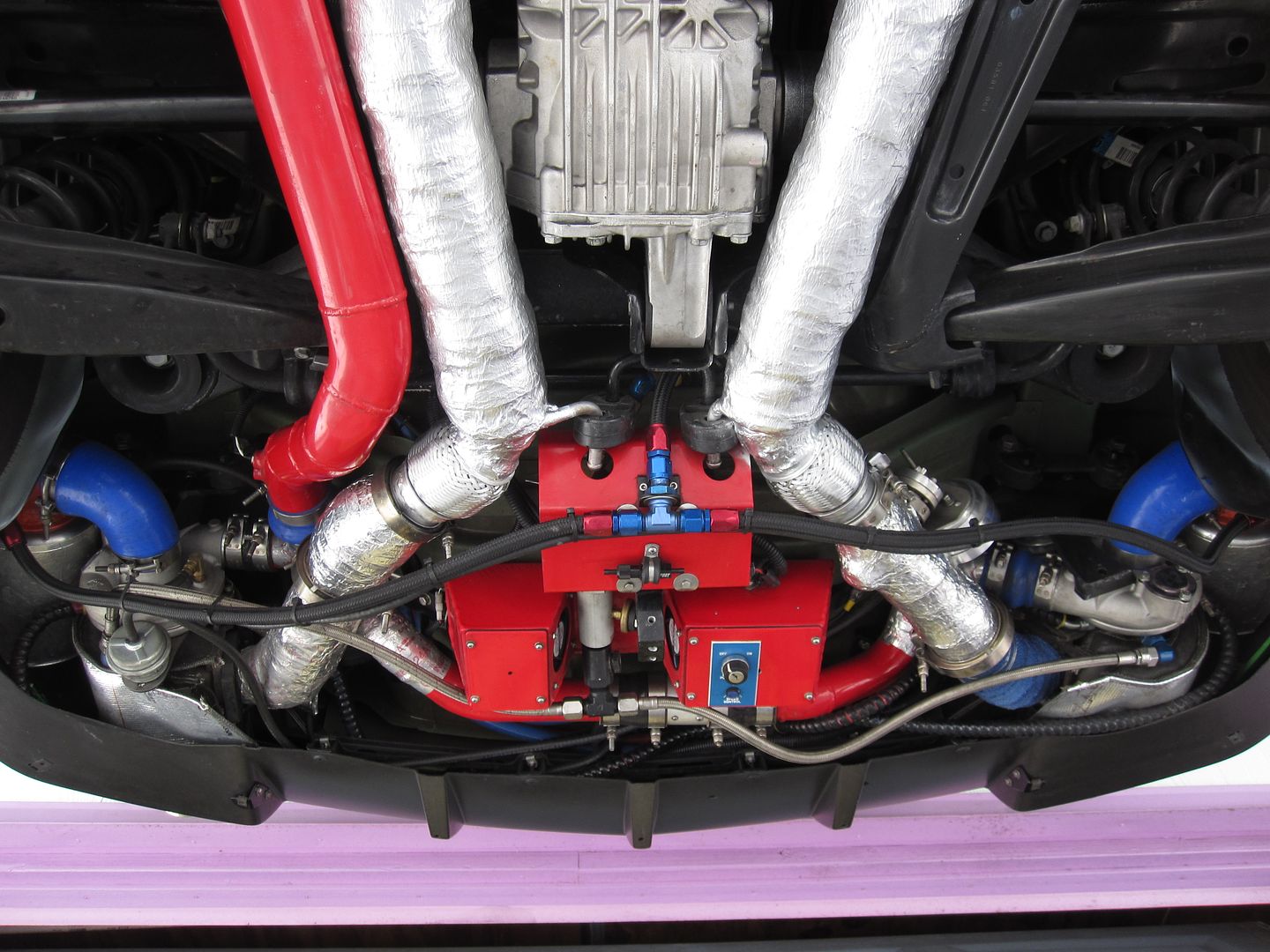

The most advanced and technically engineered GM 3.6L DI twin system in the world with all one off designs:

If your theory is correct, would we have experienced this with the hundreds of turbo systems and builds over the past 40 years? I would think at least to some extent....And here is one of our inventions that is taking intercooling to the extreme: (yes, this created some condensation, but with no ill effects)

And our centrifugal super chargers use the same systems as turbos:

So we have done more in turbo charging than most, yet have never experienced this with any other applications?

If your theory is correct, would we have experienced this with the hundreds of turbo systems and builds over the past 40 years? I would think at least to some extent....And here is one of our inventions that is taking intercooling to the extreme: (yes, this created some condensation, but with no ill effects)

And our centrifugal super chargers use the same systems as turbos:

So we have done more in turbo charging than most, yet have never experienced this with any other applications?