2005 KR 5.4 Rough Idle and Tick

#11

Well your profile doesn't give us much . Miles etc , location is canada but how cold --edmonton ??

The reason we ask is sludge is real bad up there .Valve trains look like chocolate cake frosting sometimes .Short trips going from 10f to 200f shorter than 30 minutes is not enough time to bake out moisture. Oil changes must be done in freezing cold more often and flushed ,three months or 5k won't do it plus you need a lighter oil in winter .

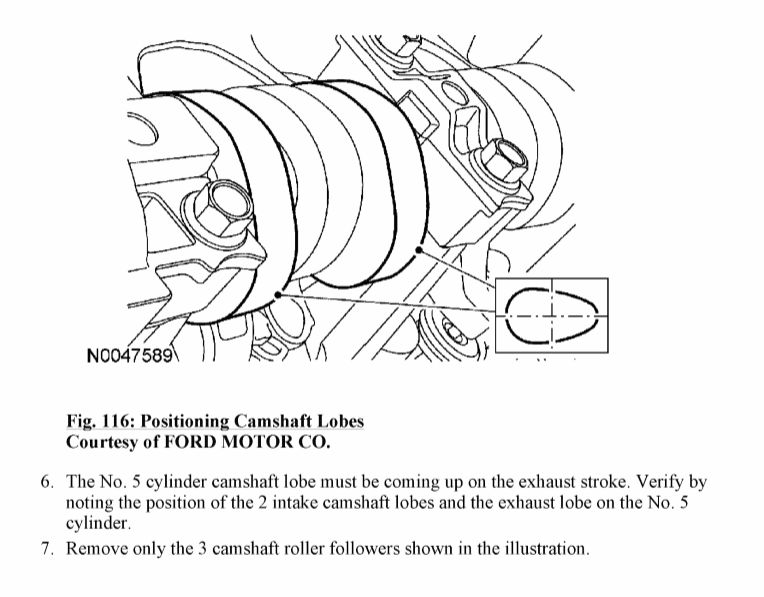

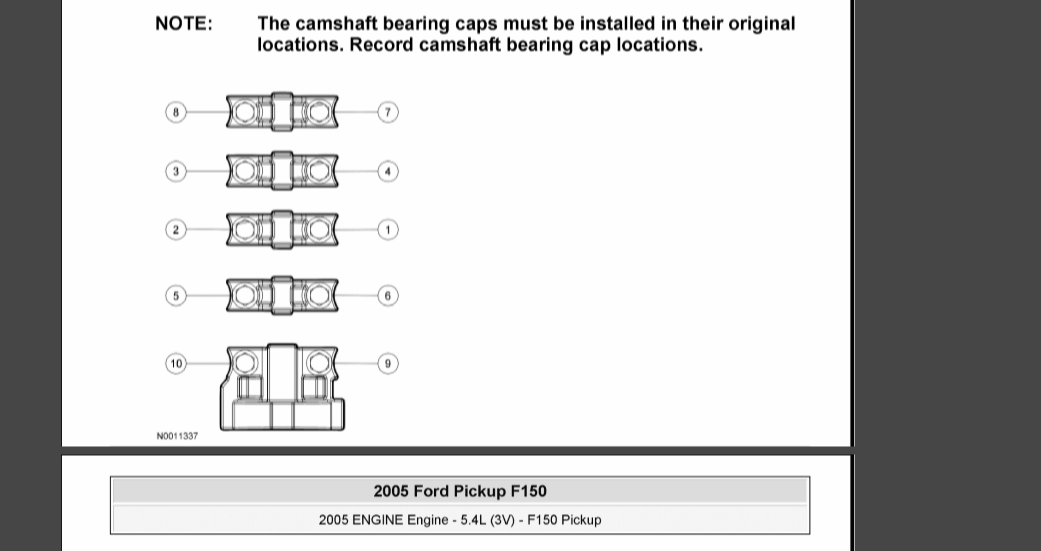

The most noise can come from rollers and lashs . Good news is you can change them from the top by jamming chain procedure and careful marking.Mine threw no 8 intake roller to the side and missed the cam . You must inspect the valve train .I replaced them all oem $265 , I would always recommend doing them during timing job .pulling cams not hard just have to follow a good procedure ,all parts must be ,marked as they have to go back exactly how they came out.

But to Be fair injectors need to be changed out on a maint schedule anyway. The are high duty cycle and to me 100k is enough .Esp the 05 era injectors ,considering their ability to hydro lock your engine and ruin it . So i agree with 150t lashs and rollers .Good luck we will help as needed .

The reason we ask is sludge is real bad up there .Valve trains look like chocolate cake frosting sometimes .Short trips going from 10f to 200f shorter than 30 minutes is not enough time to bake out moisture. Oil changes must be done in freezing cold more often and flushed ,three months or 5k won't do it plus you need a lighter oil in winter .

The most noise can come from rollers and lashs . Good news is you can change them from the top by jamming chain procedure and careful marking.Mine threw no 8 intake roller to the side and missed the cam . You must inspect the valve train .I replaced them all oem $265 , I would always recommend doing them during timing job .pulling cams not hard just have to follow a good procedure ,all parts must be ,marked as they have to go back exactly how they came out.

But to Be fair injectors need to be changed out on a maint schedule anyway. The are high duty cycle and to me 100k is enough .Esp the 05 era injectors ,considering their ability to hydro lock your engine and ruin it . So i agree with 150t lashs and rollers .Good luck we will help as needed .

I live in southern Ontario and it gets cold here. I changed the oil 1000km ago and it was like honey, not dark at all. I have the service records from Ford and previous owner treated the truck well. They did all the work trying to stop the tick but were unsuccessful.

#12

LightningRod

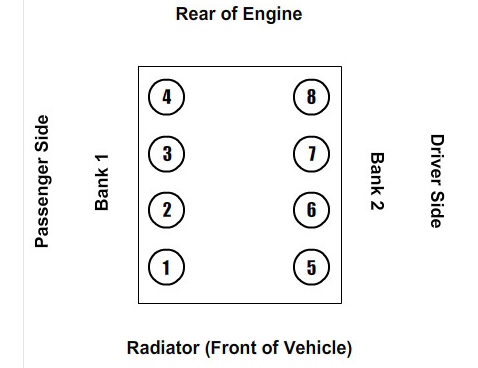

left side lifters?? looking from where? The 'passenger' side is more frequent problem for lash adjusters / rockers / and Phasers. Drivers side gets oil source from Front of block (before rod / main bearings / rear thrust bearing), Passenger side oil supply is feed from rear of block after other sources have consumed whatever flow/pressure they can.

Is your 'tick' more audible from beneath the right front wheel well? If it is, I would recommend biting the bullet and remove passenger V/C and inspect all rockers for lifter / roller pin slack while valve spring tension is relieved on each one.

Is your 'tick' more audible from beneath the right front wheel well? If it is, I would recommend biting the bullet and remove passenger V/C and inspect all rockers for lifter / roller pin slack while valve spring tension is relieved on each one.

#13

left side lifters?? looking from where? The 'passenger' side is more frequent problem for lash adjusters / rockers / and Phasers. Drivers side gets oil source from Front of block (before rod / main bearings / rear thrust bearing), Passenger side oil supply is feed from rear of block after other sources have consumed whatever flow/pressure they can.

Is your 'tick' more audible from beneath the right front wheel well? If it is, I would recommend biting the bullet and remove passenger V/C and inspect all rockers for lifter / roller pin slack while valve spring tension is relieved on each one.

Is your 'tick' more audible from beneath the right front wheel well? If it is, I would recommend biting the bullet and remove passenger V/C and inspect all rockers for lifter / roller pin slack while valve spring tension is relieved on each one.

How do you relieve valve spring tension?

The following users liked this post:

Roadblock007 (06-06-2019)

#15

05 5.4l 3v s.crew lariat

Oh heck I have to remember all that typing.You need to look at using wedge to replace phasors from the top. .When I remove cams I have them set up at the timing point at cly 1 and 5 . Using bolt sequence I slowly back off each cam bolt,the point is to not stress cam . You marked chain ,phasor ,cam with good marks . It goes back the same way ,89 inch pounds or about 7.5 foot pounds . All valve train parts must go back exactly how they came out . Mark them first .

When putting chains on it helps to have a guy on a socket on phaser bolt to move it and hold to line up while you put chain on . There are other ways to do it if you know what you are doing .

I don't use wedge ,I pull timing cover and do timing from scratch. Using vise and grips on cams with scribe marks when you don't know if it has jumped time is not my choice way of doing it .

When putting chains on it helps to have a guy on a socket on phaser bolt to move it and hold to line up while you put chain on . There are other ways to do it if you know what you are doing .

I don't use wedge ,I pull timing cover and do timing from scratch. Using vise and grips on cams with scribe marks when you don't know if it has jumped time is not my choice way of doing it .

The following users liked this post:

Roadblock007 (06-06-2019)

The following users liked this post:

Roadblock007 (06-06-2019)

#17

LightningRod

I agree with all that @redfishtd said - but seems like he is jumping the gun. We need to slow him down a notch or two. Heck, we're still in the diagnostic stage here.

To relieve valve spring tension --- just to 'Check' roller follower pin rollers bearings and lash adjusters, I'd just pull all the spark plugs and rotate the engine slowly (with socket on crank pulley) to put each roller on camshaft heel. If one has slack in it there - it WILL likely tick. If you crank it (cover chain/phaser gear oil splatter), touching one while it is jumping up and down - you can feel the tick.

If you got loose ones and proceed to the next step - follow @redfishtd advice - to the "T".

The following users liked this post:

Roadblock007 (06-06-2019)

#18

If you are familiar with adding custom gauges and importing custom sensors / parameters, You might check out THIS Torque Pro dashboard.

#19

LightningRod

"Any thoughts" you ask. Yea I'm seldom without an assortment on those - but most can't be posted on a site like this.

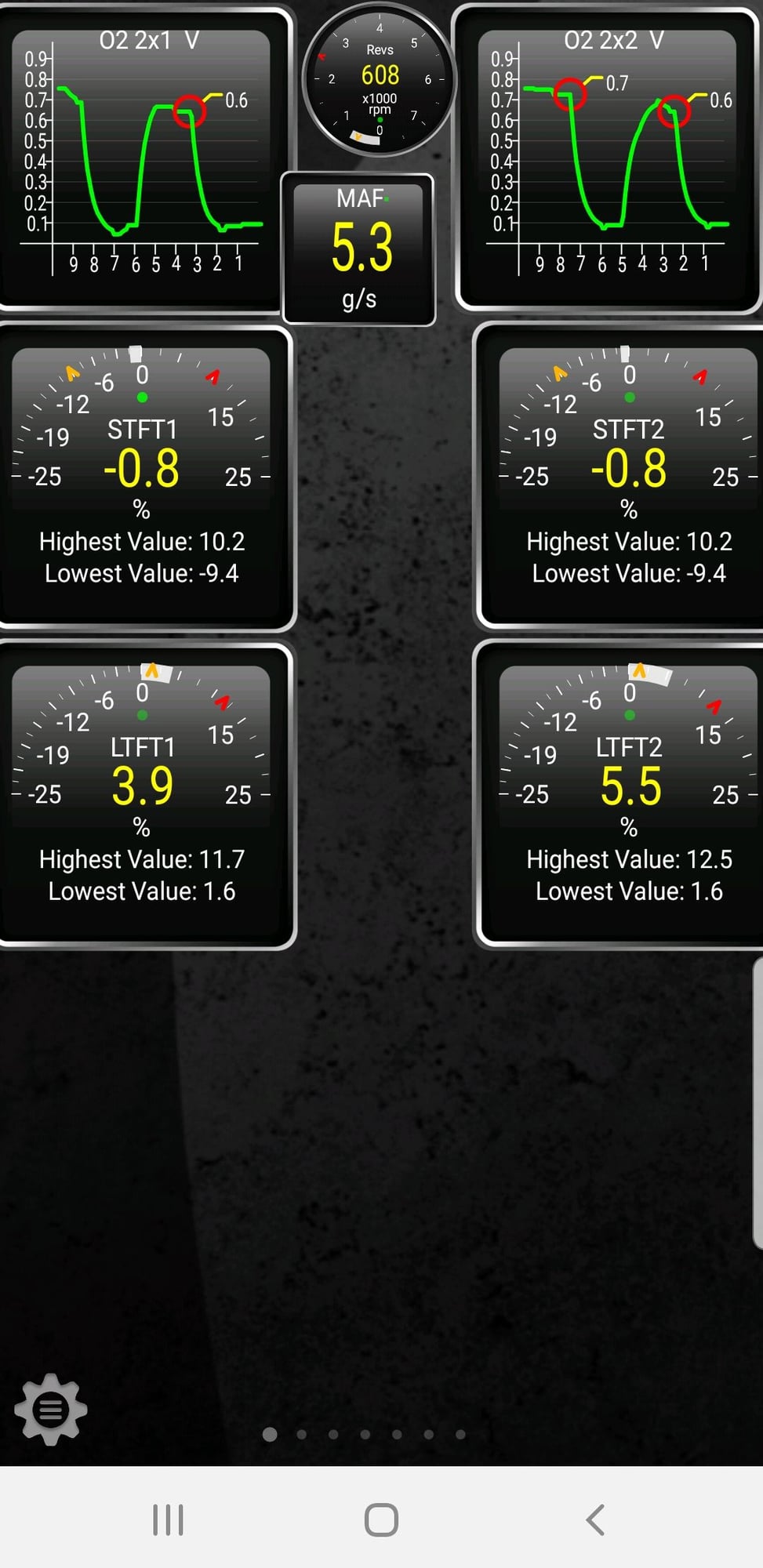

But with respect to your screenshots. You are clearly getting a handle on Torque Pro. My thoughts about them: """SWITCH SIDES WITH YOUR FUEL TRIM GAUGES TO ALIGN THEM WITH BANK 1 AND BANK 2.""" LOL

Seriously, GOOD WORK. Your O2 2x2 does NOT look good ----- IF, IF, IF. (consider the following)

Downstream O2s should not track upstream O2 sensor __UNLESS__ drive time has been insufficient to bring Cats up to operating temperature, OR under heavy engine load for an extended distance (pulling a trailer up a grade), OR after the PCM returns to closed loop after dropping into 'open loop' due to heavy acceleration. Under light cruise, or idle at full operating temperature - downstream O2's should idle along fairly smooth around .65 to .75 volts.

Your Fuel trims don't look BAD (to me) as they are well within limits (+25% LTFT, and +10% STFT) necessary to trigger lean codes. PCM is able to compensate for all component variations and maintain its calculated fuel / air mixture at upstream O2s. Although, they are 'slightly' elevated - would deserve ONLY keeping in close consideration with other related symptoms. Consider the following: Short Term trims indicate the 'trend' for LTFT's. STFT's being at or near zero means all the necessary adjustment has already migrated into the LTFT number. It's a longer term average. Trim values are maintained in a multi-dimensional table based on RPM and Engine Load (IDK specific boundaries). Elevated numbers indicate SOLELY increased injector pulse width is required. Not POSITIVELY that more fuel is being delivered. (Could be dirty 'injectors', or low fuel pressure requires longer open times. You might check Fuel Rail Pressure for ~ 39-40 psi. I am an advocate of replacing injectors if > 100k to 150K miles on them.

I do not suspect vacuum leak --- because vacuum leak affects STFT greater at lower RPMs (ie idle).

See there! I have thoughts. LOL

But with respect to your screenshots. You are clearly getting a handle on Torque Pro. My thoughts about them: """SWITCH SIDES WITH YOUR FUEL TRIM GAUGES TO ALIGN THEM WITH BANK 1 AND BANK 2.""" LOL

Seriously, GOOD WORK. Your O2 2x2 does NOT look good ----- IF, IF, IF. (consider the following)

Downstream O2s should not track upstream O2 sensor __UNLESS__ drive time has been insufficient to bring Cats up to operating temperature, OR under heavy engine load for an extended distance (pulling a trailer up a grade), OR after the PCM returns to closed loop after dropping into 'open loop' due to heavy acceleration. Under light cruise, or idle at full operating temperature - downstream O2's should idle along fairly smooth around .65 to .75 volts.

Your Fuel trims don't look BAD (to me) as they are well within limits (+25% LTFT, and +10% STFT) necessary to trigger lean codes. PCM is able to compensate for all component variations and maintain its calculated fuel / air mixture at upstream O2s. Although, they are 'slightly' elevated - would deserve ONLY keeping in close consideration with other related symptoms. Consider the following: Short Term trims indicate the 'trend' for LTFT's. STFT's being at or near zero means all the necessary adjustment has already migrated into the LTFT number. It's a longer term average. Trim values are maintained in a multi-dimensional table based on RPM and Engine Load (IDK specific boundaries). Elevated numbers indicate SOLELY increased injector pulse width is required. Not POSITIVELY that more fuel is being delivered. (Could be dirty 'injectors', or low fuel pressure requires longer open times. You might check Fuel Rail Pressure for ~ 39-40 psi. I am an advocate of replacing injectors if > 100k to 150K miles on them.

I do not suspect vacuum leak --- because vacuum leak affects STFT greater at lower RPMs (ie idle).

See there! I have thoughts. LOL

#20

"Any thoughts" you ask. Yea I'm seldom without an assortment on those - but most can't be posted on a site like this.

But with respect to your screenshots. You are clearly getting a handle on Torque Pro. My thoughts about them: """SWITCH SIDES WITH YOUR FUEL TRIM GAUGES TO ALIGN THEM WITH BANK 1 AND BANK 2.""" LOL

Seriously, GOOD WORK. Your O2 2x2 does NOT look good ----- IF, IF, IF. (consider the following)

Downstream O2s should not track upstream O2 sensor __UNLESS__ drive time has been insufficient to bring Cats up to operating temperature, OR under heavy engine load for an extended distance (pulling a trailer up a grade), OR after the PCM returns to closed loop after dropping into 'open loop' due to heavy acceleration. Under light cruise, or idle at full operating temperature - downstream O2's should idle along fairly smooth around .65 to .75 volts.

Your Fuel trims don't look BAD (to me) as they are well within limits (+25% LTFT, and +10% STFT) necessary to trigger lean codes. PCM is able to compensate for all component variations and maintain its calculated fuel / air mixture at upstream O2s. Although, they are 'slightly' elevated - would deserve ONLY keeping in close consideration with other related symptoms. Consider the following: Short Term trims indicate the 'trend' for LTFT's. STFT's being at or near zero means all the necessary adjustment has already migrated into the LTFT number. It's a longer term average. Trim values are maintained in a multi-dimensional table based on RPM and Engine Load (IDK specific boundaries). Elevated numbers indicate SOLELY increased injector pulse width is required. Not POSITIVELY that more fuel is being delivered. (Could be dirty 'injectors', or low fuel pressure requires longer open times. You might check Fuel Rail Pressure for ~ 39-40 psi. I am an advocate of replacing injectors if > 100k to 150K miles on them.

I do not suspect vacuum leak --- because vacuum leak affects STFT greater at lower RPMs (ie idle).

See there! I have thoughts. LOL

But with respect to your screenshots. You are clearly getting a handle on Torque Pro. My thoughts about them: """SWITCH SIDES WITH YOUR FUEL TRIM GAUGES TO ALIGN THEM WITH BANK 1 AND BANK 2.""" LOL

Seriously, GOOD WORK. Your O2 2x2 does NOT look good ----- IF, IF, IF. (consider the following)

Downstream O2s should not track upstream O2 sensor __UNLESS__ drive time has been insufficient to bring Cats up to operating temperature, OR under heavy engine load for an extended distance (pulling a trailer up a grade), OR after the PCM returns to closed loop after dropping into 'open loop' due to heavy acceleration. Under light cruise, or idle at full operating temperature - downstream O2's should idle along fairly smooth around .65 to .75 volts.

Your Fuel trims don't look BAD (to me) as they are well within limits (+25% LTFT, and +10% STFT) necessary to trigger lean codes. PCM is able to compensate for all component variations and maintain its calculated fuel / air mixture at upstream O2s. Although, they are 'slightly' elevated - would deserve ONLY keeping in close consideration with other related symptoms. Consider the following: Short Term trims indicate the 'trend' for LTFT's. STFT's being at or near zero means all the necessary adjustment has already migrated into the LTFT number. It's a longer term average. Trim values are maintained in a multi-dimensional table based on RPM and Engine Load (IDK specific boundaries). Elevated numbers indicate SOLELY increased injector pulse width is required. Not POSITIVELY that more fuel is being delivered. (Could be dirty 'injectors', or low fuel pressure requires longer open times. You might check Fuel Rail Pressure for ~ 39-40 psi. I am an advocate of replacing injectors if > 100k to 150K miles on them.

I do not suspect vacuum leak --- because vacuum leak affects STFT greater at lower RPMs (ie idle).

See there! I have thoughts. LOL

Any other gages I should add to my logging screen?

Is there already a port on the fuel rail to attach a pressure gage?