Write up on how I made my not so great A/C a little better.

#131

While you think this is a good idea, I will have to disagree. Let me explain. Basically lets start at the compressor discharge. Hot high temperature gas is leaving and going into the top of the condenser, that large black coil in front of your radiator where that high temperature is rejected to the air with the help of the fans and moving air across this coil. As the heat is removed, the gaseous refrigerant is converted to a high pressure, lower temperature liquid. That liquid then travels through the small pipe to the expansion device which could be a TXV or an orifice tube where this HPL is sprayed (atomized) into the bottom of the evaporator, that is the part that removes heat from the cabin. In the evaporator HPL is converted to a low pressure gas as it absorbs heat causing the cooling effect. That LPG is then routed into the compressor via the large pipe. Sometimes there is a filter dryer( a large aluminum canister) installed. In the evaporator vaporized refrigerant is converted to a gas based on the amount of ambient heat across the coil. Lets say that at 70F the conversion is finished 2/3 of the way up the evap coil. As the cabin temperature comes down the conversion to a saturated gas happens later or farther up the coil which is effectively closer to the compressor. As the temp gets lower, the less heat is absorbed and the saturated refrigerant is allowed to travel closer to the compressor. Technically this is called superheat. Superheat is there to insure the evap is operating at capacity AND to make sure that all refrigerant is converted to a gas prior to entering the compressor. While the compressor is a pump, it does not like liquid refrigerant. It likes cool dry refrigerant gas. By adding insulation to the large suction pipe you have reduced the ability of the system to absorb heat from the engine compartment thereby assuring all liquid refrigerant is converted to a gas prior to entering the compressor. Bad idea, bad, bad, bad... Now, about the other side of the system, the hot high pressure liquid small pipe. That hot liquid is sprayed into the evap and absorbs heat, the lower that temperature the better as it will flash faster and absorb more heat sooner in the evaporator. Naturally there are all kinds of calculations and gauge readings that go on refrigerant systems, but you now have the basics. Insulate the small line and leave the large one alone.

Okay, I know, I know, The large pipe (suction) is insulated in my home unit. The reason for that is keep the suction line cool enough to allow low temperature gas to cool the compressor that is 25-45 feet from the evaporator. Super heat is calculated AT the evaporator, anything extra provides cooling for the compressor. Without insulation on the suction pipe at your house will the suction gas temperature rise and not cool the compressor which you will then soon replace. I do hope that I have helped someone here. The 3/8 copper liquid line at you house is not insulated where it can reject heat along its 25-45 foot run getting cooler as it gets closer to the evap.

HVAC/Refrigeration is a fascinating science

Okay, I know, I know, The large pipe (suction) is insulated in my home unit. The reason for that is keep the suction line cool enough to allow low temperature gas to cool the compressor that is 25-45 feet from the evaporator. Super heat is calculated AT the evaporator, anything extra provides cooling for the compressor. Without insulation on the suction pipe at your house will the suction gas temperature rise and not cool the compressor which you will then soon replace. I do hope that I have helped someone here. The 3/8 copper liquid line at you house is not insulated where it can reject heat along its 25-45 foot run getting cooler as it gets closer to the evap.

HVAC/Refrigeration is a fascinating science

So the bottom line is you're saying to insulate the small (hot) line to reduce the additional heat from the engine? And the large line should be left alone?

I just did the large line and got good results cooling wise. No need for Max Cool. While your earlier post suggested not to do this, I did see where Ford put 2 short, thin lengths of insulation on the 1/2" line that only covered about 90% of the circumference. What would you think of similar lengths of better insulation? Simply a compromise between full coverage and nothing or nearly nothing that Ford supplies.

Lastly, I'm toiling with the idea of insulating the 3/8" line. Doesn't this line get hotter than ambient Engine Compartment temps? If so then ambient temp would have a cooling effect, would it not?

Sadly, I'm going out right now and take most of this stuff off till further notice.

Sure enjoyed the 30 minutes of quiet cool air in yesterdays 95* temps.

#132

So the bottom line is you're saying to insulate the small (hot) line to reduce the additional heat from the engine? And the large line should be left alone?

I just did the large line and got good results cooling wise. No need for Max Cool. While your earlier post suggested not to do this, I did see where Ford put 2 short, thin lengths of insulation on the 1/2" line that only covered about 90% of the circumference. What would you think of similar lengths of better insulation? Simply a compromise between full coverage and nothing or nearly nothing that Ford supplies.

Lastly, I'm toiling with the idea of insulating the 3/8" line. Doesn't this line get hotter than ambient Engine Compartment temps? If so then ambient temp would have a cooling effect, would it not?

Sadly, I'm going out right now and take most of this stuff off till further notice.

Sure enjoyed the 30 minutes of quiet cool air in yesterdays 95* temps.

I just did the large line and got good results cooling wise. No need for Max Cool. While your earlier post suggested not to do this, I did see where Ford put 2 short, thin lengths of insulation on the 1/2" line that only covered about 90% of the circumference. What would you think of similar lengths of better insulation? Simply a compromise between full coverage and nothing or nearly nothing that Ford supplies.

Lastly, I'm toiling with the idea of insulating the 3/8" line. Doesn't this line get hotter than ambient Engine Compartment temps? If so then ambient temp would have a cooling effect, would it not?

Sadly, I'm going out right now and take most of this stuff off till further notice.

Sure enjoyed the 30 minutes of quiet cool air in yesterdays 95* temps.

#134

Simple answer is yes, insulate small and leave the large one alone. Personally, I think that those two short pieces of rubber do more to mitigate sound and vibration than they do insulating.

by insulating the suction line you would see an improvement in cooling, that is a fact; but there is a risk of flooding refrigerant back to the compressor if you completely insulate the large pipe. You want that pipe to be cool to warm (not hot) near the compressor to insure that all of the liquid in the suction pipe is converted to gas. That can really be a problem when some well intended individual connects one of those "Cold Shot" type devices and just adds refrigerant until the can is empty. BTW......too much refrigerant will cause the system to go warm also.

For slimcubby.... I'm not reading into anything here, just trying to educate some before they do something detremental to their machines. I may have a challenge with turbos and adaptive learning or posting a quote, but I have no problem with refrigeration

This all works in theory and in practice, HOWEVER, the automobile system may be too small to see or make a difference. It logically is not cost effective to add insulation to that 4 feet of pipe to realize only a 2-3 degree difference from one end to the other four feet away.

by insulating the suction line you would see an improvement in cooling, that is a fact; but there is a risk of flooding refrigerant back to the compressor if you completely insulate the large pipe. You want that pipe to be cool to warm (not hot) near the compressor to insure that all of the liquid in the suction pipe is converted to gas. That can really be a problem when some well intended individual connects one of those "Cold Shot" type devices and just adds refrigerant until the can is empty. BTW......too much refrigerant will cause the system to go warm also.

For slimcubby.... I'm not reading into anything here, just trying to educate some before they do something detremental to their machines. I may have a challenge with turbos and adaptive learning or posting a quote, but I have no problem with refrigeration

This all works in theory and in practice, HOWEVER, the automobile system may be too small to see or make a difference. It logically is not cost effective to add insulation to that 4 feet of pipe to realize only a 2-3 degree difference from one end to the other four feet away.

Last edited by hddude103; 08-30-2013 at 05:47 PM.

#135

I just re-read the post...

Lastly, I'm toiling with the idea of insulating the 3/8" line. Doesn't this line get hotter than ambient Engine Compartment temps? If so then ambient temp would have a cooling effect, would it not?

R134a will be about between 250 and 300 psi leaving the compressor. Those temperatures are 145 and 158 f respectively. the liquid at the bottom of the condenser SHOULD be 30-35 f cooler. Those temps are 115 and 123 f also respectively. The question is: How hot is the air under the hood only 10 inches from that operating engine and turbo. In my short time working on my 3.5 I realize that it is probably the hottest engine compartment that I have ever worked in.

As you can see the relatively short, four foot section of small 3/8 line is already 115-123 f. My guess that insulating it would have immeasurable value which is likely why FOMOCO and others do not insulate it......

Lastly, I'm toiling with the idea of insulating the 3/8" line. Doesn't this line get hotter than ambient Engine Compartment temps? If so then ambient temp would have a cooling effect, would it not?

R134a will be about between 250 and 300 psi leaving the compressor. Those temperatures are 145 and 158 f respectively. the liquid at the bottom of the condenser SHOULD be 30-35 f cooler. Those temps are 115 and 123 f also respectively. The question is: How hot is the air under the hood only 10 inches from that operating engine and turbo. In my short time working on my 3.5 I realize that it is probably the hottest engine compartment that I have ever worked in.

As you can see the relatively short, four foot section of small 3/8 line is already 115-123 f. My guess that insulating it would have immeasurable value which is likely why FOMOCO and others do not insulate it......

Last edited by hddude103; 08-30-2013 at 05:49 PM.

#136

Senior Member

hddude103 - While you bring up good points I strongly disagree (and to clarify I am not an automotive ac tech, but I am a commercial/residential/industrial ac tech, but I have worked on a few different vehicle ac's).

You assume/state your lineset from your home is insulated because it is "25-45 feet from the evaporator" to the compressor, yet it would be perfectly acceptable to install a condenser/compressor less than 5' from the evaporator and still insulate the lineset. The added distance makes a difference, but most manufacturer's for example have their ac units charged such that no refrigerant is needed with a lineset less than 15-20'. Over that one needs to add refrigerant. One doesn't need to insulate the line, but cooling isn't as effective and superheat back to the compressor gets higher, which means higher pressures and that the compressor has to work harder to provide cooling. Also all the condensation from an uninsulated lineset in your home can cause other issues (wet attic insulation, mold, wood root, etc. depending on location ran).

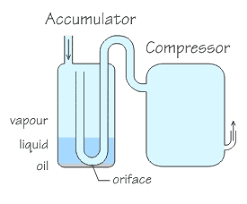

Next you mention the 'large aluminum canister' on the suction line being a filter drier, well while I am not 100% sure that is a false statement, I'd bet that is incorrect and that the 'large aluminum canister' you mention is actually a suction line accumulator. Well that device helps prevent liquid from coming back to the compressor by design. Liquid stays in the bottom, the return line to the compressor goes thru that like a horseshoe shape pulling gas off the top and a small hole on the bottom to pick up the needed return oil.

Typically (when installed) filter driers are installed upstream of the txv/orifice to catch any debris in the system that may cause a restriction here as this is the most 'sensitive' part of the system to any debris in the system. While there are suction line driers as well to protect the compressor it is very rare either are installed in smaller systems anymore, due to both added cost and better manufacturing/quality control of initial system build.

Next you mention TXV or orifice, but here if it is a TXV the TXV modulates as needed based on your suction line temperature to maintain the superheat as set by design at the TXV bulb, typically at the outlet of the evaporator. Too low of superheat sensed, the valve closes down to allow less refrigerant thru, in turn increasing the superheat. Too high of superheat the valve opens up allowing more refrigerant thru and in turn decreasing the superheat. Orifice just let's a fixed amount of refrigerant thru no matter what and given that and people run their ac/defrost even in the winter I am that much more confident the 'large aluminum canister' is a suction line accumulator. Now let's add fan speed into the mix, oh I have my ac set as cold as it can go and my ac fan set as slow as it can go, what kind of superheat you think you'll get then with/without insulating the suction line? While in this case it will be worse with insulating the suction line I just think one needs to be aware one probably shouldn't run the ac in such a manner with an insulated suction line (low temperature setting and low fan speed setting), but even at that I think it is very minor considering the way defrost works.

Next your saying the 134A will be between 250 and 300 psi leaving the compressor with a 30-35 deg F condenser Temp Delta (aka rise above ambient), well you are only running your ac when it is above 110 deg F outside aka condenser entering temperature. If not does your condenser fan have speed control to maintain that temperature when it's less than 110 deg F outside?

Again keep in mind this is only recommended for those who are complaining there ac isn't working well enough. If you ac is working fine then don't waste you time, but even at that with all things considered how often does anyone clean their evaporator coil? A dirty evaporator coil causes low superheat. Next is also the low pressure safety switches can also come into play if one does try to run the system too cold. While I am well aware a low pressure safety doesn't prevent low superheat/liquid back to the compressor, but depending on settings it can help prevent such in the case of a fan set low, dirty evap, etc.

You assume/state your lineset from your home is insulated because it is "25-45 feet from the evaporator" to the compressor, yet it would be perfectly acceptable to install a condenser/compressor less than 5' from the evaporator and still insulate the lineset. The added distance makes a difference, but most manufacturer's for example have their ac units charged such that no refrigerant is needed with a lineset less than 15-20'. Over that one needs to add refrigerant. One doesn't need to insulate the line, but cooling isn't as effective and superheat back to the compressor gets higher, which means higher pressures and that the compressor has to work harder to provide cooling. Also all the condensation from an uninsulated lineset in your home can cause other issues (wet attic insulation, mold, wood root, etc. depending on location ran).

Next you mention the 'large aluminum canister' on the suction line being a filter drier, well while I am not 100% sure that is a false statement, I'd bet that is incorrect and that the 'large aluminum canister' you mention is actually a suction line accumulator. Well that device helps prevent liquid from coming back to the compressor by design. Liquid stays in the bottom, the return line to the compressor goes thru that like a horseshoe shape pulling gas off the top and a small hole on the bottom to pick up the needed return oil.

Typically (when installed) filter driers are installed upstream of the txv/orifice to catch any debris in the system that may cause a restriction here as this is the most 'sensitive' part of the system to any debris in the system. While there are suction line driers as well to protect the compressor it is very rare either are installed in smaller systems anymore, due to both added cost and better manufacturing/quality control of initial system build.

Next you mention TXV or orifice, but here if it is a TXV the TXV modulates as needed based on your suction line temperature to maintain the superheat as set by design at the TXV bulb, typically at the outlet of the evaporator. Too low of superheat sensed, the valve closes down to allow less refrigerant thru, in turn increasing the superheat. Too high of superheat the valve opens up allowing more refrigerant thru and in turn decreasing the superheat. Orifice just let's a fixed amount of refrigerant thru no matter what and given that and people run their ac/defrost even in the winter I am that much more confident the 'large aluminum canister' is a suction line accumulator. Now let's add fan speed into the mix, oh I have my ac set as cold as it can go and my ac fan set as slow as it can go, what kind of superheat you think you'll get then with/without insulating the suction line? While in this case it will be worse with insulating the suction line I just think one needs to be aware one probably shouldn't run the ac in such a manner with an insulated suction line (low temperature setting and low fan speed setting), but even at that I think it is very minor considering the way defrost works.

Next your saying the 134A will be between 250 and 300 psi leaving the compressor with a 30-35 deg F condenser Temp Delta (aka rise above ambient), well you are only running your ac when it is above 110 deg F outside aka condenser entering temperature. If not does your condenser fan have speed control to maintain that temperature when it's less than 110 deg F outside?

Again keep in mind this is only recommended for those who are complaining there ac isn't working well enough. If you ac is working fine then don't waste you time, but even at that with all things considered how often does anyone clean their evaporator coil? A dirty evaporator coil causes low superheat. Next is also the low pressure safety switches can also come into play if one does try to run the system too cold. While I am well aware a low pressure safety doesn't prevent low superheat/liquid back to the compressor, but depending on settings it can help prevent such in the case of a fan set low, dirty evap, etc.

Last edited by gwpfan; 08-31-2013 at 01:56 AM. Reason: grammar/clarification

#137

Senior Member

Here's more details about the accumulator

Also to quote from a previous comment you simply click on Quote in the lower right hand corner of the post you want to quote. If you want to quote from multiple posts then you use the " button to the right of the Quote button on each post you want to quote.

Also this looks a lot like it...

Murray® Climate Control - A/C Accumulator With Hose Assembly

Also this looks a lot like it...

Murray® Climate Control - A/C Accumulator With Hose Assembly

Last edited by gwpfan; 08-31-2013 at 01:54 AM. Reason: ADD O'Reilly link & photo

#138

We can disagree on some points here and that's ok. I will start off by saying that you are correct, the aluminum canister is an accumulator and not a filter dryer as I stated. and as the name implies it holds refrigerant in the larger systems that usually have a TXV that can change the amount of refrigerant in the evaporator based on heat load and fan speed. Unfortunately, most automobiles us a fixed orifice tube as a metering device. You know that the charging procedure is different for each of these devices; Because the TXV will adjust to maintain a given superheat, you use subcooling to determine the system charge. In the non-TXV system (orifice, capillary tube) adjust charge by measured superheat. With regard to SH, you stated "You assume/state your lineset from your home is insulated because it is "25-45 feet from the evaporator" to the compressor, yet it would be perfectly acceptable to install a condenser/compressor less than 5' from the evaporator and still insulate the lineset". Because of the previous statement about the pre-charged lineset, I'm not sure that on the same page. Yes, when using a PCLS, you can place the compressor anywhere within the length of the LS and it will need to be insulated so cool vapor in the suction line can provide adequate comp cooling. But, if I build a system where the compressor is 4-5 feet (as it is in an auto) from the evap, you would not need to insulate to provide compressor cooling. The goal is to protect the compressor by providing adequate cooling, lubrication and minimizing floodback. Your comment about the LPS confirms the goal to protect the compressor.

Most of the other info you provided is correct but it applies to res/comm HVAC.

You stated, Next your saying the 134A will be between 250 and 300 psi leaving the compressor with a 30-35 deg F condenser Temp Delta (aka rise above ambient), well you are only running your ac when it is above 110 deg F outside aka condenser entering temperature. If not does your condenser fan have speed control to maintain that temperature when it's less than 110 deg F outside?

We again are not on the same page. You are talking about the "low ambient controls" on a residential unit. Some vehicles use a head pressure control switch to start the electric fans when equipped. The difference in the refrigerant gas temperature at the top of the condenser and the liquid temp at the bottom of the condenser is known as "sub-cooling". It should be 15F for a home unit; in an auto there are other variables which include: are the electric supplemental fans running, is the vehicle moving providing air across the cond, is the system fully charged, what are the temp and humidity of ambient air.

Most of the other info you provided is correct but it applies to res/comm HVAC.

You stated, Next your saying the 134A will be between 250 and 300 psi leaving the compressor with a 30-35 deg F condenser Temp Delta (aka rise above ambient), well you are only running your ac when it is above 110 deg F outside aka condenser entering temperature. If not does your condenser fan have speed control to maintain that temperature when it's less than 110 deg F outside?

We again are not on the same page. You are talking about the "low ambient controls" on a residential unit. Some vehicles use a head pressure control switch to start the electric fans when equipped. The difference in the refrigerant gas temperature at the top of the condenser and the liquid temp at the bottom of the condenser is known as "sub-cooling". It should be 15F for a home unit; in an auto there are other variables which include: are the electric supplemental fans running, is the vehicle moving providing air across the cond, is the system fully charged, what are the temp and humidity of ambient air.

#139

Senior Member

Agreed

Keep in mind you brought up the details about a residential system and the TXV. No one mentioned a pre-charged lineset. I simply was stating that most units technically are slightly overcharged, aka less superheat so when only having a less than 15' lineset they don't have you pull out refrigerant, nor do they tell you to remove insulation from the suction line.

Agree and disagree. Just like tuning an engine, do you think FORD charges each unit for only the area it plans to ship the truck to?

No they charge it to maintain in all/most environments it'll run it. Way north it's likely overcharged a touch or charged just right and way south undercharged.

While you may not need to insulate the compressor to provide proper cooling for the compressor, you may need to insulate the line to help provide proper cooling for the driver and passengers. Also FORD saves thousands of dollars in man hours and materials by not insulating the suction line, where in many cases people won't notice the difference. Many will just have those hot days and accept the AC performance, chalking it up to the heat outside.

Again you mention the 4-5' the heat the engine bay will add to the line set, well again what about cold winter startup and defrost? The engine bay won't hardly add anything for quite awhile and actually insulating the suction line could help to add more superheat back in such conditions. The compressor runs during defrost to help pull the moisture out of the air.

Not exactly, the refrigeration cycle is the same for all systems and superheat and subcool is the same measurements. It applies to all. While TXV's are likely rare in an auto I am sure someone somewhere has put such in.

No I was using your example and I can break that out for you.

R-134A

250 psi = ~145 deg F saturation

300 psi = ~158 deg F saturation

Then you say "the liquid at the bottom of the condenser SHOULD be 30-35 f cooler.

"Those temps are 115 and 123 f also respectively"

So at 250 psi it can only do 30 deg cooler, but at 300 psi it can do 35 deg cooler than saturation in your example.

Well cooler than what? It has to reject the heat to the outside air so in order to do so it makes the condenser pressure and temperatures 30-35 deg warmer than the outside air. In my example in the other post I just used 35 deg for both values, thus I got 110 deg outside air.

At 80 deg outside temp using your 30-35 degree delta, R-134A would be 110-115 deg F condensing temp and ~147-159 psi on the high side pressure.

Also it is rare/almost never that a residential unit has low ambient controls. These are typically only installed in commercial/industrial applications where the need arises.

You are incorrect about it should be 15 deg for a home ac unit. While it can/may be 15 deg and be perfectly acceptable it all depends on ambient conditions across both the evaporator and the condenser. Subcool could be 2-25 degrees and all be fine. Extra high load/temps indoor and outdoor = low subcool. Low temps outside and no low ambient kit = high subcool.

A typical rule of thumb is 8-10 deg f subcool for a cap tube/fixed orifice system and 10-12 deg f subcool for TXV at design conditions and at least 10 minutes of continuous runtime. Above/below design conditions and less runtime those numbers change.

Most automotive tech's never get into these kind of details as they work on so many different components, not just A/C and since it's 100% factory built system they just go off of the factory recommendations. Also many shops have systems that basically they hook up and it does most of the work for them, evacuation, charging, etc.

Again this is about "How I made my not so great A/C a little better" not about "How I made my great A/C Excellent/that much better"

Unfortunately, most automobiles us a fixed orifice tube as a metering device. You know that the charging procedure is different for each of these devices; Because the TXV will adjust to maintain a given superheat, you use subcooling to determine the system charge. In the non-TXV system (orifice, capillary tube) adjust charge by measured superheat. With regard to SH, you stated "You assume/state your lineset from your home is insulated because it is "25-45 feet from the evaporator" to the compressor, yet it would be perfectly acceptable to install a condenser/compressor less than 5' from the evaporator and still insulate the lineset". Because of the previous statement about the pre-charged lineset, I'm not sure that on the same page.

Yes, when using a PCLS, you can place the compressor anywhere within the length of the LS and it will need to be insulated so cool vapor in the suction line can provide adequate comp cooling. But, if I build a system where the compressor is 4-5 feet (as it is in an auto) from the evap, you would not need to insulate to provide compressor cooling. The goal is to protect the compressor by providing adequate cooling, lubrication and minimizing floodback. Your comment about the LPS confirms the goal to protect the compressor.

No they charge it to maintain in all/most environments it'll run it. Way north it's likely overcharged a touch or charged just right and way south undercharged.

While you may not need to insulate the compressor to provide proper cooling for the compressor, you may need to insulate the line to help provide proper cooling for the driver and passengers. Also FORD saves thousands of dollars in man hours and materials by not insulating the suction line, where in many cases people won't notice the difference. Many will just have those hot days and accept the AC performance, chalking it up to the heat outside.

Again you mention the 4-5' the heat the engine bay will add to the line set, well again what about cold winter startup and defrost? The engine bay won't hardly add anything for quite awhile and actually insulating the suction line could help to add more superheat back in such conditions. The compressor runs during defrost to help pull the moisture out of the air.

You stated, Next your saying the 134A will be between 250 and 300 psi leaving the compressor with a 30-35 deg F condenser Temp Delta (aka rise above ambient), well you are only running your ac when it is above 110 deg F outside aka condenser entering temperature. If not does your condenser fan have speed control to maintain that temperature when it's less than 110 deg F outside?

No I was using your example and I can break that out for you.

R-134A

250 psi = ~145 deg F saturation

300 psi = ~158 deg F saturation

Then you say "the liquid at the bottom of the condenser SHOULD be 30-35 f cooler.

"Those temps are 115 and 123 f also respectively"

So at 250 psi it can only do 30 deg cooler, but at 300 psi it can do 35 deg cooler than saturation in your example.

Well cooler than what? It has to reject the heat to the outside air so in order to do so it makes the condenser pressure and temperatures 30-35 deg warmer than the outside air. In my example in the other post I just used 35 deg for both values, thus I got 110 deg outside air.

At 80 deg outside temp using your 30-35 degree delta, R-134A would be 110-115 deg F condensing temp and ~147-159 psi on the high side pressure.

Also it is rare/almost never that a residential unit has low ambient controls. These are typically only installed in commercial/industrial applications where the need arises.

Some vehicles use a head pressure control switch to start the electric fans when equipped. The difference in the refrigerant gas temperature at the top of the condenser and the liquid temp at the bottom of the condenser is known as "sub-cooling". It should be 15F for a home unit; in an auto there are other variables which include: are the electric supplemental fans running, is the vehicle moving providing air across the cond, is the system fully charged, what are the temp and humidity of ambient air.

You are incorrect about it should be 15 deg for a home ac unit. While it can/may be 15 deg and be perfectly acceptable it all depends on ambient conditions across both the evaporator and the condenser. Subcool could be 2-25 degrees and all be fine. Extra high load/temps indoor and outdoor = low subcool. Low temps outside and no low ambient kit = high subcool.

A typical rule of thumb is 8-10 deg f subcool for a cap tube/fixed orifice system and 10-12 deg f subcool for TXV at design conditions and at least 10 minutes of continuous runtime. Above/below design conditions and less runtime those numbers change.

Most automotive tech's never get into these kind of details as they work on so many different components, not just A/C and since it's 100% factory built system they just go off of the factory recommendations. Also many shops have systems that basically they hook up and it does most of the work for them, evacuation, charging, etc.

Again this is about "How I made my not so great A/C a little better" not about "How I made my great A/C Excellent/that much better"

Last edited by gwpfan; 08-31-2013 at 02:09 PM. Reason: clarifications and Ford cost savings, made not mad

#140

Well, I must admit that this thread is getting a bit (ok, way too) technical for me to understand...

That said, I did insulate my suction line this morning and wanted to offer a few practical tips for anyone that is planning to do this:

1. As some other folks have already mentioned, make sure you get the smaller of the two sizes of Armaflex at Home Depot/Lowes. I made the mistake of getting the bigger size originally...

2. You should only need one six foot section of Armaflex pipe insulation (for a 5.4L engine configuration, that is). I bought two as I wasn't sure but was able to insulate from the firewall to right before the compressor and have about 1 foot left over. Will be returning the other one to Home Depot today.

The whole project took about 2 hours, but that's only because I work slow and was methodical about wrapping the whole line in aluminum tape as well (in order to provide a better seal and alleviate any concerns of the Armalfex melting).

That said, I did insulate my suction line this morning and wanted to offer a few practical tips for anyone that is planning to do this:

1. As some other folks have already mentioned, make sure you get the smaller of the two sizes of Armaflex at Home Depot/Lowes. I made the mistake of getting the bigger size originally...

2. You should only need one six foot section of Armaflex pipe insulation (for a 5.4L engine configuration, that is). I bought two as I wasn't sure but was able to insulate from the firewall to right before the compressor and have about 1 foot left over. Will be returning the other one to Home Depot today.

The whole project took about 2 hours, but that's only because I work slow and was methodical about wrapping the whole line in aluminum tape as well (in order to provide a better seal and alleviate any concerns of the Armalfex melting).