Stock 5.0L Piping Size?

#4

HOPEFUL

iTrader: (1)

as to WHY, I have no clue. but I have a resonator delete pipe for my 2012 5.0 sitting right next to me and I know for a fact the connection before the muffler is in fact a 2.5" pipe.

I am also going with a 3" pipe, but the onlty reason why is because I already had it in my garage for other plans that never panned out, so why spend $4-600 bux on an exhaust system when I have this already.

I think a lot of people just live by the false impression that bigger is always better when it comes to exhaust systems.

I am also going with a 3" pipe, but the onlty reason why is because I already had it in my garage for other plans that never panned out, so why spend $4-600 bux on an exhaust system when I have this already.

I think a lot of people just live by the false impression that bigger is always better when it comes to exhaust systems.

#5

Puppet King, Sock Master

#6

#7

Senior Member

Sock Puppet - Which, if not used with a corresponding performance upgrades, can have a negative effect.

ROT (Rule Of Thumb) for naturally aspirated, not highly modified ...

The following 2 users liked this post by gDMJoe:

08drenalin (03-25-2017),

bb123 (06-06-2017)

Trending Topics

#9

Senior Member

Ugh...I get so sick of the myth that a dual 3" exhaust is too big for a 300+hp engine

Back pressure, Exhaust velocity and scavenging.

The myth: “engines need some backpressure.”

One of the most misunderstood concepts in exhaust theory is backpressure. People love to talk about backpressure on message boards with no real understanding of what it is and what its consequences are. I'm sure many of you have heard or read the phrase "engines need some backpressure" when discussing exhaust upgrades. That phrase is in fact completely inaccurate and a wholly misguided notion.

How the myth came about:

It is easy to see how this misunderstanding arises. Lets’ say that Max puts a 3-inch system on his normally aspirated car. He soon realizes that he has lost power right through the power band. The connection is made in his throbbing brain….

Put on 3" pipe = loss of backpressure = loss of power.

Max erroneously concludes that you need backpressure to retain performance. He has ignored the need for exhaust gas velocity to get that scavenge effect.

The other myth: “engines can get burned valves from not enough backpressure”

How this myth came about:

The other reason why people say "backpressure is good" is because they hear that cars (or motorcycles) that have had performance exhaust work done to them would then go on to burn exhaust valves. Now, it is true that such valve burning has occurred as a result of the exhaust mods, but it isn't due merely to a lack of backpressure.

The internal combustion engine is a complex, dynamic collection of different systems working together to convert the stored power in gasoline into mechanical energy to push a car down the road. Anytime one of these systems are modified, that mod will also indirectly affect the other systems, as well.

Now, valve burning occurs as a result of a very lean-burning engine. In order to achieve a theoretical optimal combustion, an engine needs 14.7 parts of oxygen by mass to 1 part of gasoline (again, by mass). This is referred to as a stochiometric (chemically correct) mixture, and is commonly referred to as a 14.7:1 mix. If an engine burns with less oxygen present (13:1, 12:1, etc...), it is said to run rich. Conversely, if the engine runs with more oxygen present (16:1, 17:1, etc...), it is said to run lean. Today's engines are designed to run at 14.7:1 for normally cruising, with rich mixtures on acceleration or warm-up, and lean mixtures while decelerating.

Getting back to the discussion, the reason that exhaust valves burn is because the engine is burning lean. Normal engines will tolerate lean burning for a little bit, but not for sustained periods of time. The reason why the engine is burning lean to begin with is that the reduction in backpressure is causing more air to be drawn into the combustion chamber than before. Earlier cars (and motorcycles) with carburetion often could not adjust for his.

Once these vehicles received performance mods that reduced backpressure, they tended to burn valves because of the resulting over-lean condition. This, incidentally, also provides a basis for the "torque increase" seen if backpressure is maintained. As the fuel/air mixture becomes leaner, the resultant combustion will produce progressively less and less of the force needed to produce torque.

Some basic exhaust theory

Your exhaust system is designed to evacuate gases from the combustion chamber quickly and efficiently. Exhaust gases are not produced in a smooth stream; exhaust gases originate in pulses. A 4 cylinder motor will have 4 distinct pulses per complete engine cycle; a 6 cylinder has 6 pulses and so on. The more pulses that are produced, the more continuous the exhaust flow. Backpressure can be loosely defined as the resistance to positive flow - in this case, the resistance to positive flow of the exhaust stream.

Backpressure and velocity.

Some people operate under the misguided notion that wider pipes are more effective at clearing the combustion chamber than narrower pipes. It's not hard to see how this misconception is appealing - wider pipes have the capability to flow more than narrower pipes. So if they have the ability to flow more, why isn't "wider is better" a good rule of thumb for exhaust upgrading? In a word - VELOCITY. I'm sure that all of you have at one time used a garden hose w/o a spray nozzle on it. If you let the water just run unrestricted out of the house it flows at a rather slow rate. However, if you take your finger and cover part of the opening, the water will flow out at a much, much, faster rate.

The astute exhaust designer knows that you must balance flow capacity with velocity. You want the exhaust gases to exit the chamber and speed along at the highest velocity possible - you want a FAST exhaust stream. If you have two exhaust pulses of equal volume, one in a 2" pipe and one in a 3" pipe, the pulse in the 2" pipe will be traveling considerably FASTER than the pulse in the 3" pipe. While it is true that the narrower the pipe, the higher the velocity of the exiting gases, you want make sure the pipe is wide enough so that there is as little backpressure as possible while maintaining suitable exhaust gas velocity.

Backpressure in its most extreme form can lead to reversion of the exhaust stream - that is to say the exhaust flows backwards, which is not good. The trick is to have a pipe that that is as narrow as possible while having as close to zero backpressure as possible at the RPM range you want your power band to be located at. Exhaust pipe diameters are best suited to a particular RPM range. A smaller pipe diameter will produce higher exhaust velocities at a lower RPM but create unacceptably high amounts of backpressure at high rpm. Thus if your power band is located 2-3000 RPM you'd want a narrower pipe than if your power band is located at 8-9000RPM.

Many engineers try to work around the RPM specific nature of pipe diameters by using setups that are capable of creating a similar effect as a change in pipe diameter on the fly. The most advanced is Ferrari's which consists of two exhaust paths after the header - at low RPM only one path is open to maintain exhaust velocity, but as RPM climbs and exhaust volume increases, the second path is opened to curb backpressure - since there is greater exhaust volume there is no loss in flow velocity. BMW and Nissan use a simpler and less effective method - there is a single exhaust path to the muffler; the muffler has two paths; one path is closed at low RPM but both are open at high RPM.

So why is exhaust velocity so important?

The faster an exhaust pulse moves, the better it can scavenge out all of the spent gasses during valve overlap. The guiding principles of exhaust pulse scavenging are a bit beyond the scope of this doc but the general idea is a fast moving pulse creates a low pressure area behind it. This low pressure area acts as a vacuum and draws along the air behind it. A similar example would be a vehicle traveling at a high rate of speed on a dusty road. There is a low pressure area immediately behind the moving vehicle - dust particles get sucked into this low pressure area causing it to collect on the back of the vehicle. This effect is most noticeable on vans and hatchbacks which tend to create large trailing low pressure areas - giving rise to the numerous "wash me please" messages written in the thickly collected dust on the rear door(s).

Conclusion.

SO it turns out that engines don't need backpressure, they need as high a flow velocity as possible with as little backpressure as possible.

Cited from various diffrent website. If anyone notices anything i got wrong or did not include please send me a messege and i'll take care of it. -Poet.

http://www.tristatetuners.com/forum/.../t-116159.html

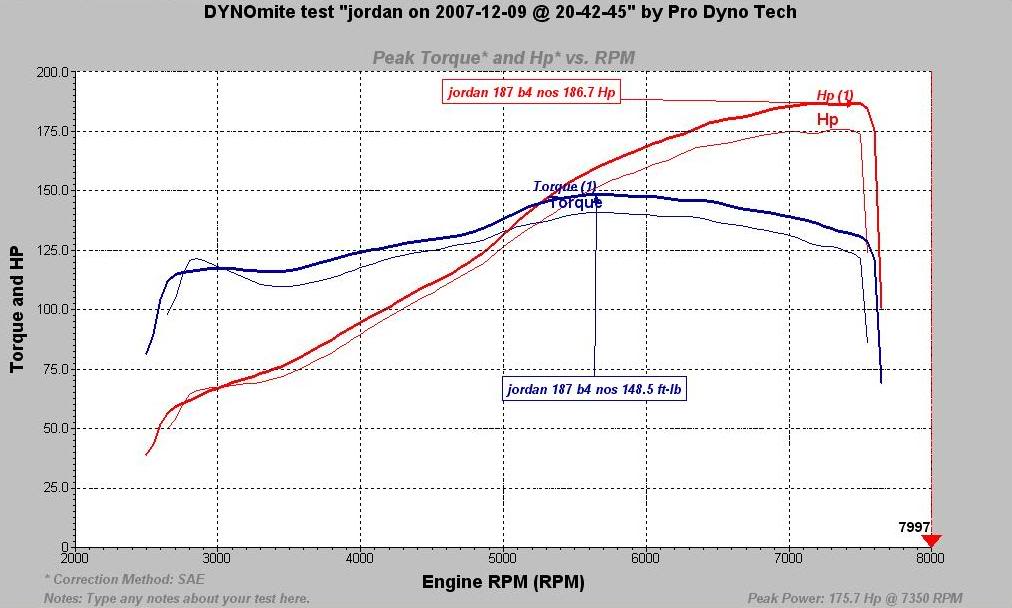

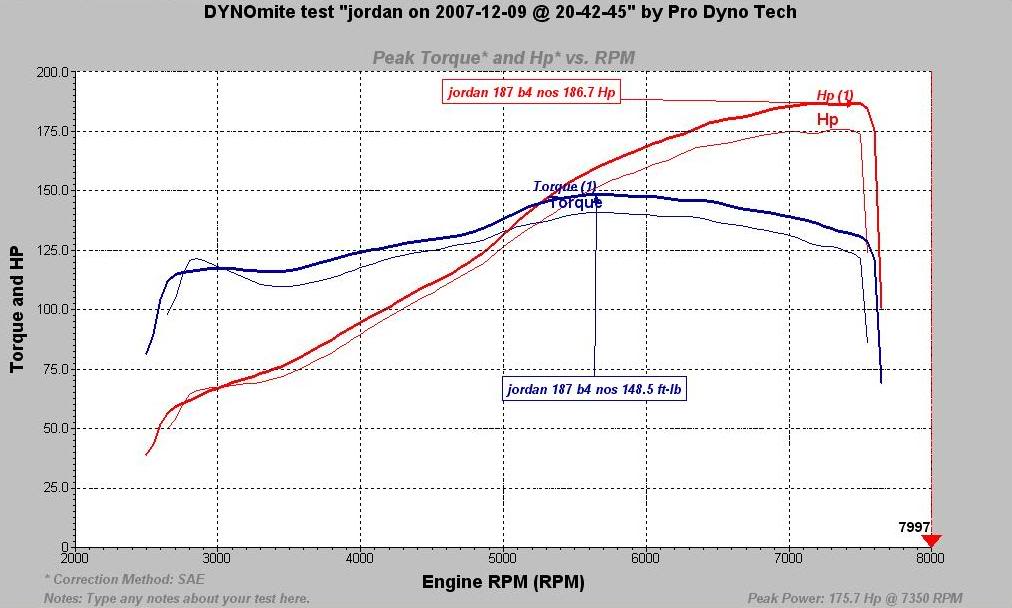

Don't you think if a little 2.2L 200hp 4 banger (below) can benefit from a 3" exhuast, a 5.0L V8 with a 360hp engine could too?

This engine below comes stock with 2.25" piping. The thin lines are it being upgraded to a 2.5" exhaust, and the thicker lines are 3". Yes, once again, it's a 2.2L 4 Cylinder (H22) running a 3" exhaust, and it didn't lose anything. In theory, our 5.0's with almost 400hp will benefit from either one 6" exhaust, or two 3" duals from the header back

It's all about TUNING AFTER the upgraded exhaust.

Back pressure, Exhaust velocity and scavenging.

The myth: “engines need some backpressure.”

One of the most misunderstood concepts in exhaust theory is backpressure. People love to talk about backpressure on message boards with no real understanding of what it is and what its consequences are. I'm sure many of you have heard or read the phrase "engines need some backpressure" when discussing exhaust upgrades. That phrase is in fact completely inaccurate and a wholly misguided notion.

How the myth came about:

It is easy to see how this misunderstanding arises. Lets’ say that Max puts a 3-inch system on his normally aspirated car. He soon realizes that he has lost power right through the power band. The connection is made in his throbbing brain….

Put on 3" pipe = loss of backpressure = loss of power.

Max erroneously concludes that you need backpressure to retain performance. He has ignored the need for exhaust gas velocity to get that scavenge effect.

The other myth: “engines can get burned valves from not enough backpressure”

How this myth came about:

The other reason why people say "backpressure is good" is because they hear that cars (or motorcycles) that have had performance exhaust work done to them would then go on to burn exhaust valves. Now, it is true that such valve burning has occurred as a result of the exhaust mods, but it isn't due merely to a lack of backpressure.

The internal combustion engine is a complex, dynamic collection of different systems working together to convert the stored power in gasoline into mechanical energy to push a car down the road. Anytime one of these systems are modified, that mod will also indirectly affect the other systems, as well.

Now, valve burning occurs as a result of a very lean-burning engine. In order to achieve a theoretical optimal combustion, an engine needs 14.7 parts of oxygen by mass to 1 part of gasoline (again, by mass). This is referred to as a stochiometric (chemically correct) mixture, and is commonly referred to as a 14.7:1 mix. If an engine burns with less oxygen present (13:1, 12:1, etc...), it is said to run rich. Conversely, if the engine runs with more oxygen present (16:1, 17:1, etc...), it is said to run lean. Today's engines are designed to run at 14.7:1 for normally cruising, with rich mixtures on acceleration or warm-up, and lean mixtures while decelerating.

Getting back to the discussion, the reason that exhaust valves burn is because the engine is burning lean. Normal engines will tolerate lean burning for a little bit, but not for sustained periods of time. The reason why the engine is burning lean to begin with is that the reduction in backpressure is causing more air to be drawn into the combustion chamber than before. Earlier cars (and motorcycles) with carburetion often could not adjust for his.

Once these vehicles received performance mods that reduced backpressure, they tended to burn valves because of the resulting over-lean condition. This, incidentally, also provides a basis for the "torque increase" seen if backpressure is maintained. As the fuel/air mixture becomes leaner, the resultant combustion will produce progressively less and less of the force needed to produce torque.

Some basic exhaust theory

Your exhaust system is designed to evacuate gases from the combustion chamber quickly and efficiently. Exhaust gases are not produced in a smooth stream; exhaust gases originate in pulses. A 4 cylinder motor will have 4 distinct pulses per complete engine cycle; a 6 cylinder has 6 pulses and so on. The more pulses that are produced, the more continuous the exhaust flow. Backpressure can be loosely defined as the resistance to positive flow - in this case, the resistance to positive flow of the exhaust stream.

Backpressure and velocity.

Some people operate under the misguided notion that wider pipes are more effective at clearing the combustion chamber than narrower pipes. It's not hard to see how this misconception is appealing - wider pipes have the capability to flow more than narrower pipes. So if they have the ability to flow more, why isn't "wider is better" a good rule of thumb for exhaust upgrading? In a word - VELOCITY. I'm sure that all of you have at one time used a garden hose w/o a spray nozzle on it. If you let the water just run unrestricted out of the house it flows at a rather slow rate. However, if you take your finger and cover part of the opening, the water will flow out at a much, much, faster rate.

The astute exhaust designer knows that you must balance flow capacity with velocity. You want the exhaust gases to exit the chamber and speed along at the highest velocity possible - you want a FAST exhaust stream. If you have two exhaust pulses of equal volume, one in a 2" pipe and one in a 3" pipe, the pulse in the 2" pipe will be traveling considerably FASTER than the pulse in the 3" pipe. While it is true that the narrower the pipe, the higher the velocity of the exiting gases, you want make sure the pipe is wide enough so that there is as little backpressure as possible while maintaining suitable exhaust gas velocity.

Backpressure in its most extreme form can lead to reversion of the exhaust stream - that is to say the exhaust flows backwards, which is not good. The trick is to have a pipe that that is as narrow as possible while having as close to zero backpressure as possible at the RPM range you want your power band to be located at. Exhaust pipe diameters are best suited to a particular RPM range. A smaller pipe diameter will produce higher exhaust velocities at a lower RPM but create unacceptably high amounts of backpressure at high rpm. Thus if your power band is located 2-3000 RPM you'd want a narrower pipe than if your power band is located at 8-9000RPM.

Many engineers try to work around the RPM specific nature of pipe diameters by using setups that are capable of creating a similar effect as a change in pipe diameter on the fly. The most advanced is Ferrari's which consists of two exhaust paths after the header - at low RPM only one path is open to maintain exhaust velocity, but as RPM climbs and exhaust volume increases, the second path is opened to curb backpressure - since there is greater exhaust volume there is no loss in flow velocity. BMW and Nissan use a simpler and less effective method - there is a single exhaust path to the muffler; the muffler has two paths; one path is closed at low RPM but both are open at high RPM.

So why is exhaust velocity so important?

The faster an exhaust pulse moves, the better it can scavenge out all of the spent gasses during valve overlap. The guiding principles of exhaust pulse scavenging are a bit beyond the scope of this doc but the general idea is a fast moving pulse creates a low pressure area behind it. This low pressure area acts as a vacuum and draws along the air behind it. A similar example would be a vehicle traveling at a high rate of speed on a dusty road. There is a low pressure area immediately behind the moving vehicle - dust particles get sucked into this low pressure area causing it to collect on the back of the vehicle. This effect is most noticeable on vans and hatchbacks which tend to create large trailing low pressure areas - giving rise to the numerous "wash me please" messages written in the thickly collected dust on the rear door(s).

Conclusion.

SO it turns out that engines don't need backpressure, they need as high a flow velocity as possible with as little backpressure as possible.

Cited from various diffrent website. If anyone notices anything i got wrong or did not include please send me a messege and i'll take care of it. -Poet.

http://www.tristatetuners.com/forum/.../t-116159.html

Don't you think if a little 2.2L 200hp 4 banger (below) can benefit from a 3" exhuast, a 5.0L V8 with a 360hp engine could too?

This engine below comes stock with 2.25" piping. The thin lines are it being upgraded to a 2.5" exhaust, and the thicker lines are 3". Yes, once again, it's a 2.2L 4 Cylinder (H22) running a 3" exhaust, and it didn't lose anything. In theory, our 5.0's with almost 400hp will benefit from either one 6" exhaust, or two 3" duals from the header back

It's all about TUNING AFTER the upgraded exhaust.

Last edited by jonbar87; 06-07-2012 at 09:57 PM.

The following 2 users liked this post by jonbar87:

08drenalin (03-11-2017),

aiobst (05-25-2014)

#10

Senior Member

I found it interesting that my stock system was 2.5" into the muffler, and 3" out. The Borla system I put on was 3" in and 2.5" out (duals). Numbers don't matter to me, so long as it sounds bad-*****.

I went for a 4" pipe instead

I went for a 4" pipe instead