About those "catch cans"

#11

Senior Member

I hear ya on the "...cheap and it can't hurt..." - but that's part of my concern too. Can it hurt? What if the can gets full or isnt draining? Is there a risk of tons of gunk flooding in all at once as opposed to small trickles over time? What else don't I/we know about these things?

In my line of work - and in life in general - I see/hear people with that mentality - and it's actually dangerous at times. It's like a chain letter you get in email or some alert or heart wrenching story someone sends on facebook. You're told to forward it at once! So many people don't bother to fact check and just pass it on - when 90% of the time - it's bunk! It wastes other people's time, sometimes costs them small and large amounts of money (the scams out there and the number of people that believe in them is mind blowing), causes virus and other problems to spread to computers, phones, and takes businesses and life essential medical equipment down. All because someone thought - "oh, what will it hurt?". They just had no idea.

Again - no disrespect - but I'd really like to see some actual proof of the benefits. Not anecdotal evidence based on the number of years and number of people who've used a product. God help us if we ALL started making decisions simple because other people did without doing our own due diligence.

I know you didn't bring this up, but I've heard some pretty "diverse" claims about this "cheap" little bit of "insurance". Including how it's been used by thousands and for years - but then the same person who makes that claim stresses how the EcoBoost is SOOOOO different and needs it so much more than other models and typed of engines. So, is that person saying the non-ecoboost people didn't need it then?

I dunno. I'm irked. I really want to get some straight answers. Do some eco's have carbon issues? Sure. And some of us had CAC issues while most did not (my 2013 was fixed by the updated intercooler btw). Some get flats for no good reason straight out of the factory. With this many units - there's going to be variances in product & material quality. Stuff happens.

I am not saying these cans aren't needed - yet. But so far - for what they claim to be doing for the ecoboost engine - I have seen ZERO proof.

1. There is gunk getting into the motor.

2. A can fills up with gunk.

Now - can ANYONE prove to me that #1 is no longer occurring because we have a can filling with gunk??? Simply because #2 exists does NOT MEAN #1 has been mitigated.

THAT is the proof I'm looking for on the EcoBoost engine. And then I'd gladly buy one to prevent gunk from getting to my engine and POSSIBLY getting to the point that it could foul my valve operation.

Ya know - what hurts this argument is when I hear that motors with 10k or 20k have experienced failures due to this. Yet - the vast majority of engines haven't had that problem and have way more miles...just doesn't add up.

In my line of work - and in life in general - I see/hear people with that mentality - and it's actually dangerous at times. It's like a chain letter you get in email or some alert or heart wrenching story someone sends on facebook. You're told to forward it at once! So many people don't bother to fact check and just pass it on - when 90% of the time - it's bunk! It wastes other people's time, sometimes costs them small and large amounts of money (the scams out there and the number of people that believe in them is mind blowing), causes virus and other problems to spread to computers, phones, and takes businesses and life essential medical equipment down. All because someone thought - "oh, what will it hurt?". They just had no idea.

Again - no disrespect - but I'd really like to see some actual proof of the benefits. Not anecdotal evidence based on the number of years and number of people who've used a product. God help us if we ALL started making decisions simple because other people did without doing our own due diligence.

I know you didn't bring this up, but I've heard some pretty "diverse" claims about this "cheap" little bit of "insurance". Including how it's been used by thousands and for years - but then the same person who makes that claim stresses how the EcoBoost is SOOOOO different and needs it so much more than other models and typed of engines. So, is that person saying the non-ecoboost people didn't need it then?

I dunno. I'm irked. I really want to get some straight answers. Do some eco's have carbon issues? Sure. And some of us had CAC issues while most did not (my 2013 was fixed by the updated intercooler btw). Some get flats for no good reason straight out of the factory. With this many units - there's going to be variances in product & material quality. Stuff happens.

I am not saying these cans aren't needed - yet. But so far - for what they claim to be doing for the ecoboost engine - I have seen ZERO proof.

1. There is gunk getting into the motor.

2. A can fills up with gunk.

Now - can ANYONE prove to me that #1 is no longer occurring because we have a can filling with gunk??? Simply because #2 exists does NOT MEAN #1 has been mitigated.

THAT is the proof I'm looking for on the EcoBoost engine. And then I'd gladly buy one to prevent gunk from getting to my engine and POSSIBLY getting to the point that it could foul my valve operation.

Ya know - what hurts this argument is when I hear that motors with 10k or 20k have experienced failures due to this. Yet - the vast majority of engines haven't had that problem and have way more miles...just doesn't add up.

#12

Brodozin' through life

iTrader: (3)

If you guys want a good laugh, go over to the BMW forum and look at how bad the valves look on a 335i turbo after 30k miles. 10x worse than that pic previously posted. Im not gonna put one of these catch cans on my truck, because i get a new car pretty much every year anyways. so its a waste

#13

Senior Member

I was going to say that if your truck needed it, Ford would've put them in there from the factory, but that would be wrong. They put an a/c unit in there and they sometimes don't work as advertised either. Kind of like back window defrosters that blow out, less mpg's than rated, CAC problems, drive line snap crackle pops, repeated dead batteries, etc.

I think I have enough potential problems to worry about. Catch can or not. If i thought i needed it, I'd buy one. I just don't think i need it. Just my .02

I think I have enough potential problems to worry about. Catch can or not. If i thought i needed it, I'd buy one. I just don't think i need it. Just my .02

#14

I've never heard of anyone installing a catch can to keep their valves clean, but in theory it should help.

Everyone I know that has installed them has done it to keep oil out of the combustion chamber. Oil causes detonation, not something you want when spraying or running forced induction.

Higher boost levels can easily increase crank case pressure enough to force oil through a stock pcv system instead of just vapor.

A vented crank case is a good thing, sealed pcv systems are an epa thing to keep oil out of the waterways.

Everyone I know that has installed them has done it to keep oil out of the combustion chamber. Oil causes detonation, not something you want when spraying or running forced induction.

Higher boost levels can easily increase crank case pressure enough to force oil through a stock pcv system instead of just vapor.

A vented crank case is a good thing, sealed pcv systems are an epa thing to keep oil out of the waterways.

#15

It's just sort of funny how some of the biggest catch can advocates on this forum...

happen to be guys that sell them.

What about magnets on the fuel line? They are reputed to double, even triple gas mileage. And, what about all those fuel tank additives? Autozone pushes them on me everytime I shop there! Clean those valves right up!

Heck, we'll get this truck to run so clean that medical experiments could be performed in the combustion chambers!

happen to be guys that sell them.

What about magnets on the fuel line? They are reputed to double, even triple gas mileage. And, what about all those fuel tank additives? Autozone pushes them on me everytime I shop there! Clean those valves right up!

Heck, we'll get this truck to run so clean that medical experiments could be performed in the combustion chambers!

#16

And this is where "your mileage may vary" comes from. I had one on my 5.0 stang and when I traded it in simply put it on the truck (JLT if you care). Does it catch ALL THE OILS? NO. Does it catch most? yeah. I plan to keep this truck and rebuild the motor when it won't last any longer, so to me its worth it. I don't mind having to empty it from time to time in the name of better maintenance. Ford didn't put on on it mostly because they don't want to induce a maintenance item that needs so much attention for "small" gain. (IMO) For the record I have about 6,000 miles on the truck and have filled up the can twice. (can is 2 oz capacity)

#17

There are several threads showing DI engines and the intake valves with and without a PROPER catchcan that actually catches all the oil. You must first understand 99% of the cans on the market sold as catching all the oil only catch 15-30% max, and only a few do 80% or better.

Here is an example:

https://www.f150forum.com/f70/5-0-up...s-test-254381/

This covers over 3 months and thousands of miles in the most exact independent test. Start from the beginning and see how drastic the difference is, and UPR has now greatly improved their offering as a result of this test.

So, unless you have a RX, SMC, EliteE2, Apex, or the latest to be released UPR, you have a can (no matter the brand, all have been tested like this) that only catches a fraction of the oil and gunk causing this coking. The rest allow most to pass right through the can.

Now, pictures can be food all over the internet from actual techs that work on DI engines...all makes and models:

https://www.google.com/search?q=Inta...ction&tbm=isch

The video by Brian, a Ford Master tech understands most of this and works with the Ford engineers at Detroit. No auto maker publicly acknowledges this is an issue to date, yet all have severe issues with this to one degree or another.

Good thread on those actually doing the intake valve cleaning:

https://www.f150forum.com/f70/2011-f...ild-up-266605/

If you have read and viewed the pictures of the difference between port injection and direct injection, it is easy to see why this is an issue, and the only way to prevent it is by installing a good effective catchcan system. The issue with the ecoboost is the PCV system used is one that can only work with a naturally aspirated engine, not a turbo charged engine like the EcoBoost, so ONLY the RX, Elite E2, and new yet to be released UPR system can accomplish this modification to ensure constant steady evacuation in both non-boost and boost. Here are some examples of what is caught with a properly designed system that addresses this:

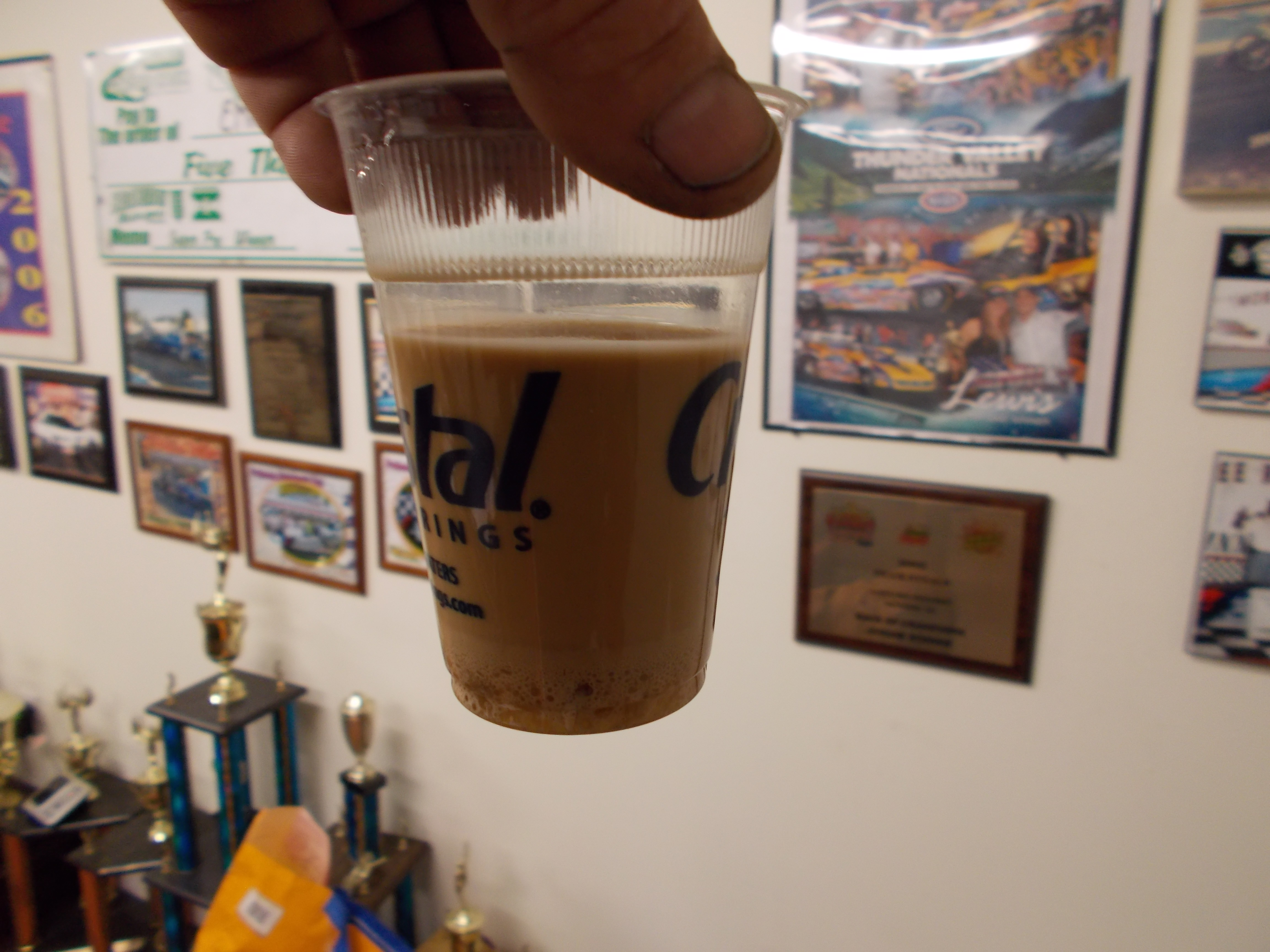

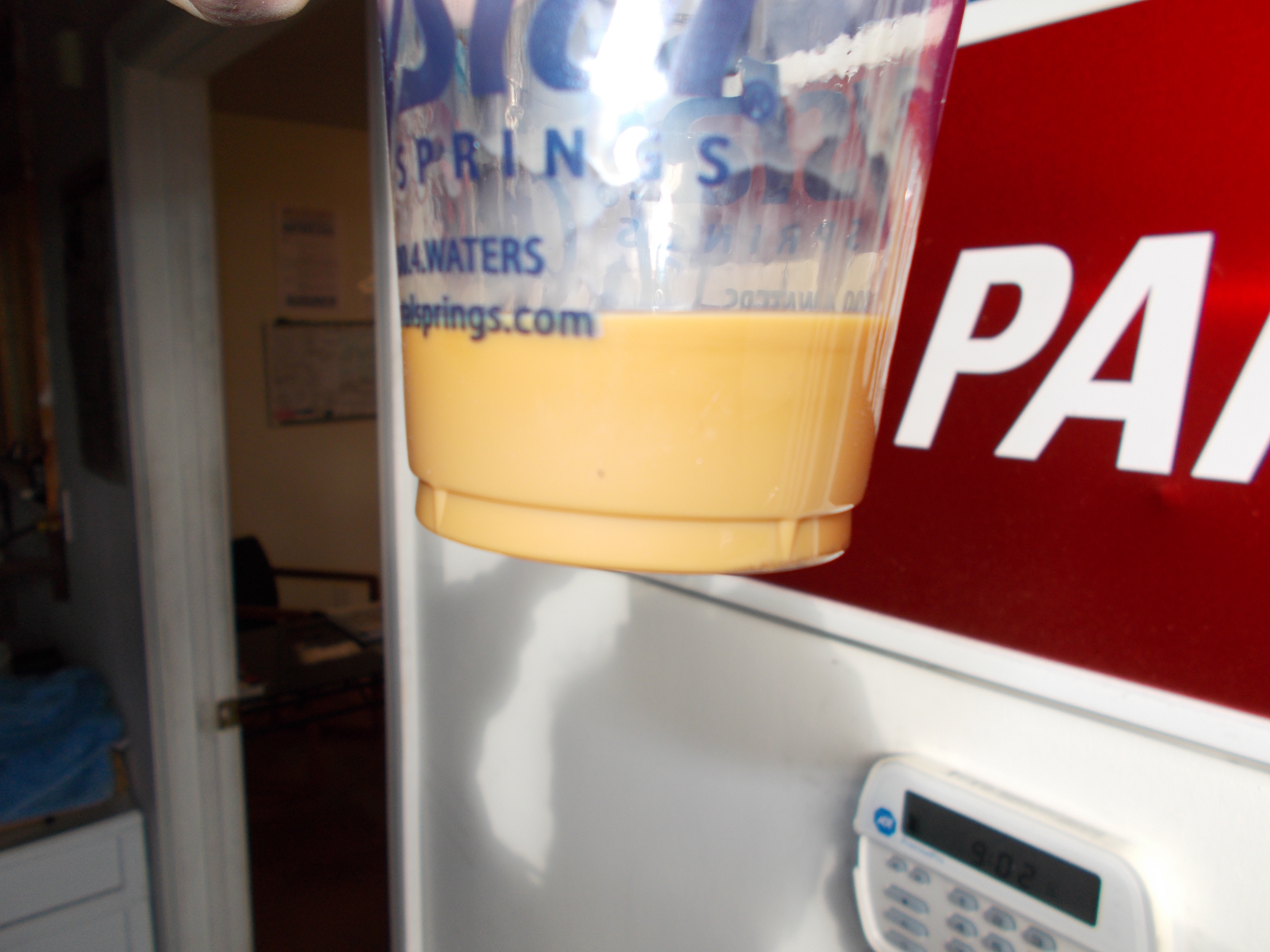

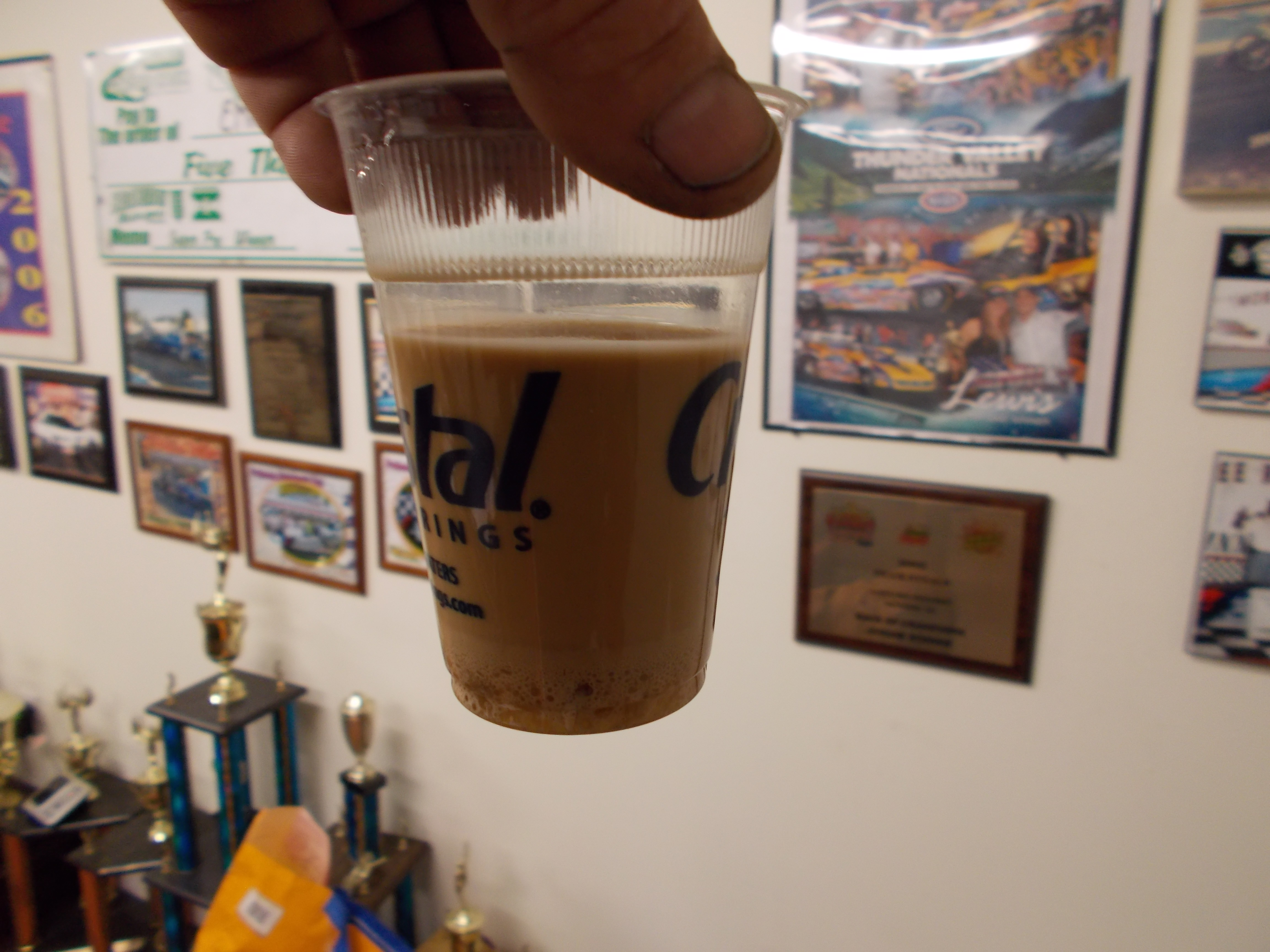

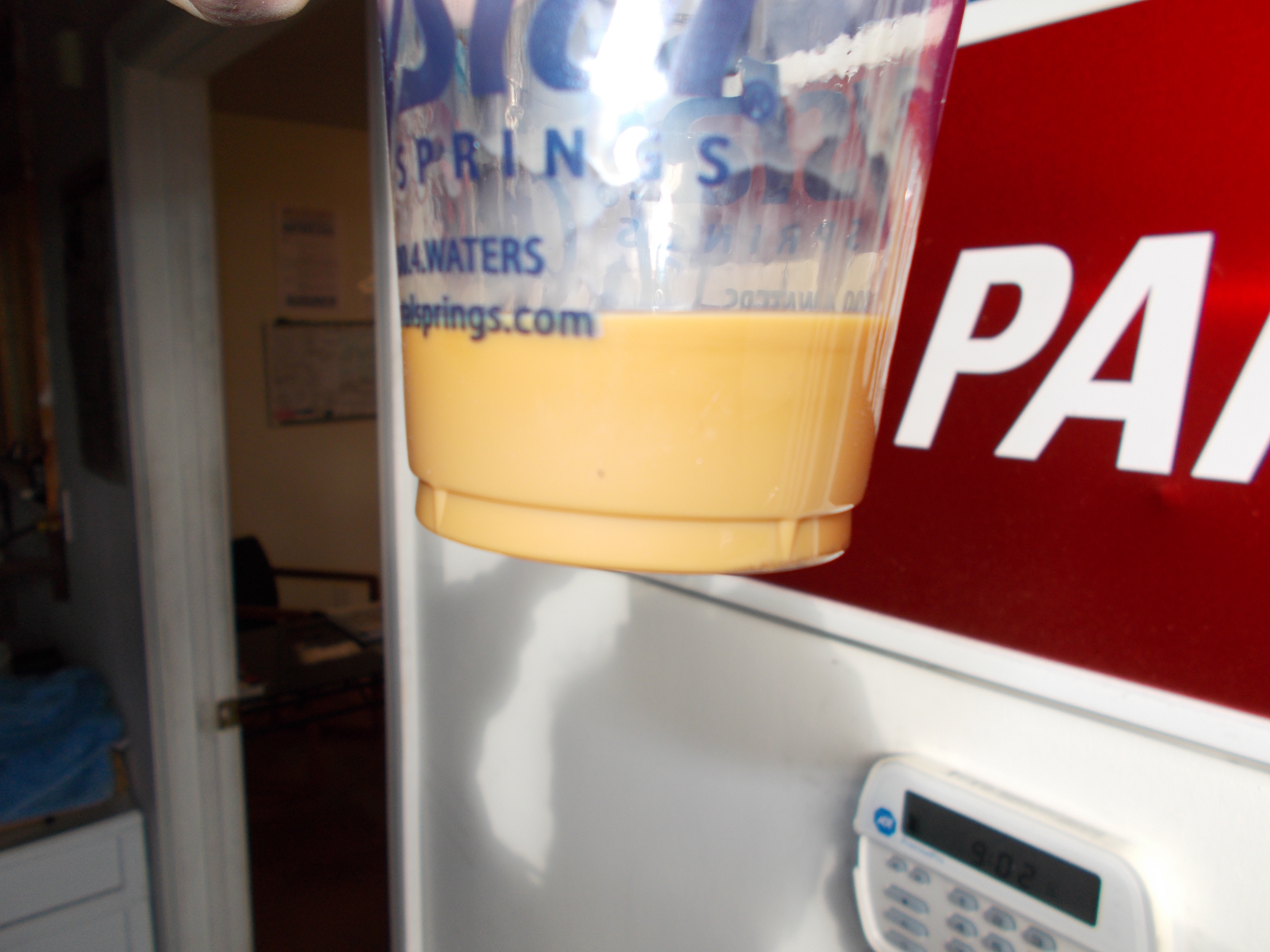

Winter and cold temps are far worse than summer:

where the average NA engine catches mainly oil and the other contaminates such as soot and carbon particles.

So, you are asking for before and after of engines with a can installed.....I can provide a test vehicle with 68,000 miles with the RX can from new (was 20-40 miles or so on it, brought it in day after picking it up from dealer) VS the same vehicle and V6 DI engine w/out, but it is the new GM DI V6, NOT the ecoboost. The effect is the same as your stopping the compounds that create the coking, but the GM is worse in rate of coking than the ecoboost. Still can give you an idea of the results:

Now this is alot of data, and some has been posted before, but this is the best we have so far (pics may not come through as I copied and pasted from another thread...if not I will try and edit and add them,):

This is 68,000 miles on one installed RX system next day after picking car up at dealer VS 55,000 miles w/now can on. Same engine, same vehicle, same year:

Intercooler at 15k miles w/no can....notice the amount of baked on residue has restricted the flow through the core already to a point, and is insulating it reducing the ability to transfer heat:

This image has been resized. Click this bar to view the full image. The original image is sized 640x326.

16k miles with RX system installed at less than 200 miles (new). Notice zero deposits or baked on residue...even on the SC rotors:

This image has been resized. Click this bar to view the full image. The original image is sized 640x359.

This image has been resized. Click this bar to view the full image. The original image is sized 640x359.

55,000 miles with no can:

This image has been resized. Click this bar to view the full image. The original image is sized 640x480.

This image has been resized. Click this bar to view the full image. The original image is sized 640x480.

Different vehicle at app 40k miles w/no can, same engine disassembled to do entire valve job as valve guides were worn excessively due to the deposits on the valve stems:

68,000 miles w/RX system installed at less than 100 miles (new)

This image has been resized. Click this bar to view the full image. The original image is sized 640x480.

Only a dry light coating without the clumped oily big flow obstructing deposits the without pictures show.

These would be the most accurate over an extended time. We would like to also have the vehicle back in at 100k miles to scope to see results at that time and hopefully longer. This has been over 4 years to get to the 68k mark and customer we hope keeps car longer.

Now here is a picture of the same engine, but the LY7 version that had Port Injection (same engine, same displacement but before DI was added) to show at app 114k miles zero deposits due to the old style port injection constantly showering the valves with detergent fuel preventing any deposits.....and note the spray pattern where it hit in the port as well no deposits:

Here is an example:

https://www.f150forum.com/f70/5-0-up...s-test-254381/

This covers over 3 months and thousands of miles in the most exact independent test. Start from the beginning and see how drastic the difference is, and UPR has now greatly improved their offering as a result of this test.

So, unless you have a RX, SMC, EliteE2, Apex, or the latest to be released UPR, you have a can (no matter the brand, all have been tested like this) that only catches a fraction of the oil and gunk causing this coking. The rest allow most to pass right through the can.

Now, pictures can be food all over the internet from actual techs that work on DI engines...all makes and models:

https://www.google.com/search?q=Inta...ction&tbm=isch

The video by Brian, a Ford Master tech understands most of this and works with the Ford engineers at Detroit. No auto maker publicly acknowledges this is an issue to date, yet all have severe issues with this to one degree or another.

Good thread on those actually doing the intake valve cleaning:

https://www.f150forum.com/f70/2011-f...ild-up-266605/

If you have read and viewed the pictures of the difference between port injection and direct injection, it is easy to see why this is an issue, and the only way to prevent it is by installing a good effective catchcan system. The issue with the ecoboost is the PCV system used is one that can only work with a naturally aspirated engine, not a turbo charged engine like the EcoBoost, so ONLY the RX, Elite E2, and new yet to be released UPR system can accomplish this modification to ensure constant steady evacuation in both non-boost and boost. Here are some examples of what is caught with a properly designed system that addresses this:

Winter and cold temps are far worse than summer:

where the average NA engine catches mainly oil and the other contaminates such as soot and carbon particles.

So, you are asking for before and after of engines with a can installed.....I can provide a test vehicle with 68,000 miles with the RX can from new (was 20-40 miles or so on it, brought it in day after picking it up from dealer) VS the same vehicle and V6 DI engine w/out, but it is the new GM DI V6, NOT the ecoboost. The effect is the same as your stopping the compounds that create the coking, but the GM is worse in rate of coking than the ecoboost. Still can give you an idea of the results:

Now this is alot of data, and some has been posted before, but this is the best we have so far (pics may not come through as I copied and pasted from another thread...if not I will try and edit and add them,):

This is 68,000 miles on one installed RX system next day after picking car up at dealer VS 55,000 miles w/now can on. Same engine, same vehicle, same year:

Intercooler at 15k miles w/no can....notice the amount of baked on residue has restricted the flow through the core already to a point, and is insulating it reducing the ability to transfer heat:

This image has been resized. Click this bar to view the full image. The original image is sized 640x326.

16k miles with RX system installed at less than 200 miles (new). Notice zero deposits or baked on residue...even on the SC rotors:

This image has been resized. Click this bar to view the full image. The original image is sized 640x359.

This image has been resized. Click this bar to view the full image. The original image is sized 640x359.

55,000 miles with no can:

This image has been resized. Click this bar to view the full image. The original image is sized 640x480.

This image has been resized. Click this bar to view the full image. The original image is sized 640x480.

Different vehicle at app 40k miles w/no can, same engine disassembled to do entire valve job as valve guides were worn excessively due to the deposits on the valve stems:

68,000 miles w/RX system installed at less than 100 miles (new)

This image has been resized. Click this bar to view the full image. The original image is sized 640x480.

Only a dry light coating without the clumped oily big flow obstructing deposits the without pictures show.

These would be the most accurate over an extended time. We would like to also have the vehicle back in at 100k miles to scope to see results at that time and hopefully longer. This has been over 4 years to get to the 68k mark and customer we hope keeps car longer.

Now here is a picture of the same engine, but the LY7 version that had Port Injection (same engine, same displacement but before DI was added) to show at app 114k miles zero deposits due to the old style port injection constantly showering the valves with detergent fuel preventing any deposits.....and note the spray pattern where it hit in the port as well no deposits:

#18

On the effects of intake valve coking, there are SAE papers, Patents, etc. Here are just a few, and they go back quite away's so this is studied, and studied, and studied:

In the box is all the reference info for the entire study, etc.

Publication number US4811701 A

Publication type Grant

Application number US 07/201,894

Publication date Mar 14, 1989

Filing date Jun 3, 1988

Priority date Jun 6, 1987

Fee status Lapsed

Also published as DE3719077A1, DE3719077C2

Inventors Horst Buhl, Wolfgang Kleinekathofer, Eggert Tank

Original Assignee Daimler-Benz Aktiengesellschaft

Export Citation BiBTeX, EndNote, RefMan

Patent Citations (6), Referenced by (11), Classifications (11),Legal Events (5)

External Links: USPTO, USPTO Assignment, Espacenet

The coking of valves is a problem which has long been known, in particular in the case of inlet valves of Otto engines. Coking is understood to mean black, hard deposits which are produced mainly by combustion and decomposition residues of the fuel.

The requirements, which have been increasing for some years, imposed on the emission behavior, higher power outputs and lower fuel consumption, result in engines which are operated with a leaner fuel/air mixture. These requirements, as well as the use of unleaded fuel, result in the valves being more easily coked, and a coking of the valves manifests itself in a more troublesome manner than before.

The negative effects of inlet valve coking include poor cold running, poor gas admission, particularly in the warming-up phase, an increase in the fuel consumption and pollutant emission associated therewith, as well as a drop in power due to interference in the inlet air passage and out-of-true engine running. In addition, coke particles may damage the valve seating surfaces, which results in leaky valves.

Attempts to prevent coking of the inlet valves have included adding additives to the fuel, and also providing the valves with a layer which prevents deposits. Thus, it is shown in German Unpublished Patent Application No. 3,517,914 to provide inlet valves with a polytetrafluoroethylene layer. However, in practice such layers have not resulted in success.

References from the Audi engines and the studies, effects, attempted solutions, etc.:

A5/S5:

S5 FSI engines doomed due to intake manifold carbon build-up ? CONCERN

Audi A5 3.2 v6 FSI - carbon issues? CONCERN EXTERNAL

Carbon Build up at 35K PICS

A6 3.2:

Carbon buildup CEL TSB Update EXPERIENCE EXTERNAL

RS4:

RS4: Intake Manifold Carbon Build-Up & Clean Up PICS

RS4: ** PART 2 ** Intake Manifold Carbon Build-Up & Clean U PICS

RS4 only 263whp flat from 6k rpm ?!?! PICS

Sea Foam useage? CONCERN

Cost to Clean Carbon? CONCERN

My RS4 under the knife... PICS

Fuel adatives.... PICS EXTERNAL

RS4 owners READ this! CONCERN

RS4 Owners Step in. What I feel to be very important. It's a long read. CONCERN

Need help, RS4 in shop for MILs, how does valve cleaning get authorized? CONCERN

Dyno after port, polish, manifold flap removal PICS EXTERNAL

Dyno info for the day... PICS EXTERNAL

***** Official Carbon Build-Up Thread ***** POLL

Carbon Build-up 101? CONCERN

KryptoniK's RS4 PES S/C Build PICS

2008 RS4 Carbon buildup EXPERIENCE EXTERNAL

FSI Engines - Audi RS4 Engine Oil-Related Deposits PICS EXTERNAL

RS4 B7 Carbon Buildup CONCERN EXTERNAL

Update on carbon cleaning.... EXPERIENCE EXTERNAL

My RS4 Carbon Build-up Story PICS

RS4 Supercharger Project Has Started Pics PICS

RS4 carbon cleaning finished !!!!!!! EXPERIENCE PICS

RS4 Piston Damage from Carbon Build-up PICS

RS4 : to prevent carbon build up, i think this product will work. CONCERN

RS4 inspected by AOA for CB EXPERIENCE

my RS4 needs help CONCERN

Throwin' Codes at 9900 miles - 2008 RS4 EXPERIENCE

Thinking of buying an RSs4. Does it have carbon problems CONCERN

B6 S4 paid off... 20K to put down on used Rs4 with lower miles.. Cant do it! CONCERN

My RS4 dyno numbers... PICS

R8 4.2:

FSI Carbon Buildup CONCERN

TT Mk2:

carbon buildup problem with TFSI - serious worry CONCERN EXTERNAL

Problem Synopsis

The general consensus is that the build-up that forms under normal operation can decrease engine power within a relatively low amount of milage. Most anecdotal evidence shows that when theintake valves are cleaned, engine returns to spec-rated horsepower and torque. This build-up is thought to affect power in as little as 10,000 miles though few people have routinely removed their intake manifolds to document the build-up progress.

Variables

A wide-range of variables have been included in reports of build-up. A common theme is that this occurs despite tier 1 fuel and Audi recommended oils. Reports have also come in from all over the world, suggesting it's not localized to any particular region's fuel, environment or emission standards.

Indicators

Severe cases of build-up can potentially trip misfire CEL codes though in most cases, the car simply produces less power and does not indicate malfunction. Those that have cleaned their intake manifolds explain a burst of acceleration under WOT at 6k RPMs (2nd gear)(applies to RS4/R8 4.2). Dyno results for affected cars seem to be anywhere up to 40hp below quoted stock HP on the 4.2 V8 FSI engine.

Solutions

To remove build-up, only a manual physical cleaning of the intake valves and vanes has shown to be able to completely remove the carbon of which Audi will not warrant unless there are continual misfires occuring. To prevent the issue from reoccurring, oil catch cans are the most frequently raised potential solution in addition to methanol injection. At least one thread has cited both of these systems were in-use and build-up still occurred.

There are a number of temporary cleaning solutions that are available. The effectiveness of these has not been discussed. Some of these include: BG 44k and Direct Injection Power 3. Audi's solution is a fuel additive to clean the injector ports, though this has been shown to have little to no effect on carbon build-up on the intake valves.

In the box is all the reference info for the entire study, etc.

Publication number US4811701 A

Publication type Grant

Application number US 07/201,894

Publication date Mar 14, 1989

Filing date Jun 3, 1988

Priority date Jun 6, 1987

Fee status Lapsed

Also published as DE3719077A1, DE3719077C2

Inventors Horst Buhl, Wolfgang Kleinekathofer, Eggert Tank

Original Assignee Daimler-Benz Aktiengesellschaft

Export Citation BiBTeX, EndNote, RefMan

Patent Citations (6), Referenced by (11), Classifications (11),Legal Events (5)

External Links: USPTO, USPTO Assignment, Espacenet

The coking of valves is a problem which has long been known, in particular in the case of inlet valves of Otto engines. Coking is understood to mean black, hard deposits which are produced mainly by combustion and decomposition residues of the fuel.

The requirements, which have been increasing for some years, imposed on the emission behavior, higher power outputs and lower fuel consumption, result in engines which are operated with a leaner fuel/air mixture. These requirements, as well as the use of unleaded fuel, result in the valves being more easily coked, and a coking of the valves manifests itself in a more troublesome manner than before.

The negative effects of inlet valve coking include poor cold running, poor gas admission, particularly in the warming-up phase, an increase in the fuel consumption and pollutant emission associated therewith, as well as a drop in power due to interference in the inlet air passage and out-of-true engine running. In addition, coke particles may damage the valve seating surfaces, which results in leaky valves.

Attempts to prevent coking of the inlet valves have included adding additives to the fuel, and also providing the valves with a layer which prevents deposits. Thus, it is shown in German Unpublished Patent Application No. 3,517,914 to provide inlet valves with a polytetrafluoroethylene layer. However, in practice such layers have not resulted in success.

References from the Audi engines and the studies, effects, attempted solutions, etc.:

A5/S5:

S5 FSI engines doomed due to intake manifold carbon build-up ? CONCERN

Audi A5 3.2 v6 FSI - carbon issues? CONCERN EXTERNAL

Carbon Build up at 35K PICS

A6 3.2:

Carbon buildup CEL TSB Update EXPERIENCE EXTERNAL

RS4:

RS4: Intake Manifold Carbon Build-Up & Clean Up PICS

RS4: ** PART 2 ** Intake Manifold Carbon Build-Up & Clean U PICS

RS4 only 263whp flat from 6k rpm ?!?! PICS

Sea Foam useage? CONCERN

Cost to Clean Carbon? CONCERN

My RS4 under the knife... PICS

Fuel adatives.... PICS EXTERNAL

RS4 owners READ this! CONCERN

RS4 Owners Step in. What I feel to be very important. It's a long read. CONCERN

Need help, RS4 in shop for MILs, how does valve cleaning get authorized? CONCERN

Dyno after port, polish, manifold flap removal PICS EXTERNAL

Dyno info for the day... PICS EXTERNAL

***** Official Carbon Build-Up Thread ***** POLL

Carbon Build-up 101? CONCERN

KryptoniK's RS4 PES S/C Build PICS

2008 RS4 Carbon buildup EXPERIENCE EXTERNAL

FSI Engines - Audi RS4 Engine Oil-Related Deposits PICS EXTERNAL

RS4 B7 Carbon Buildup CONCERN EXTERNAL

Update on carbon cleaning.... EXPERIENCE EXTERNAL

My RS4 Carbon Build-up Story PICS

RS4 Supercharger Project Has Started Pics PICS

RS4 carbon cleaning finished !!!!!!! EXPERIENCE PICS

RS4 Piston Damage from Carbon Build-up PICS

RS4 : to prevent carbon build up, i think this product will work. CONCERN

RS4 inspected by AOA for CB EXPERIENCE

my RS4 needs help CONCERN

Throwin' Codes at 9900 miles - 2008 RS4 EXPERIENCE

Thinking of buying an RSs4. Does it have carbon problems CONCERN

B6 S4 paid off... 20K to put down on used Rs4 with lower miles.. Cant do it! CONCERN

My RS4 dyno numbers... PICS

R8 4.2:

FSI Carbon Buildup CONCERN

TT Mk2:

carbon buildup problem with TFSI - serious worry CONCERN EXTERNAL

Problem Synopsis

The general consensus is that the build-up that forms under normal operation can decrease engine power within a relatively low amount of milage. Most anecdotal evidence shows that when theintake valves are cleaned, engine returns to spec-rated horsepower and torque. This build-up is thought to affect power in as little as 10,000 miles though few people have routinely removed their intake manifolds to document the build-up progress.

Variables

A wide-range of variables have been included in reports of build-up. A common theme is that this occurs despite tier 1 fuel and Audi recommended oils. Reports have also come in from all over the world, suggesting it's not localized to any particular region's fuel, environment or emission standards.

Indicators

Severe cases of build-up can potentially trip misfire CEL codes though in most cases, the car simply produces less power and does not indicate malfunction. Those that have cleaned their intake manifolds explain a burst of acceleration under WOT at 6k RPMs (2nd gear)(applies to RS4/R8 4.2). Dyno results for affected cars seem to be anywhere up to 40hp below quoted stock HP on the 4.2 V8 FSI engine.

Solutions

To remove build-up, only a manual physical cleaning of the intake valves and vanes has shown to be able to completely remove the carbon of which Audi will not warrant unless there are continual misfires occuring. To prevent the issue from reoccurring, oil catch cans are the most frequently raised potential solution in addition to methanol injection. At least one thread has cited both of these systems were in-use and build-up still occurred.

There are a number of temporary cleaning solutions that are available. The effectiveness of these has not been discussed. Some of these include: BG 44k and Direct Injection Power 3. Audi's solution is a fuel additive to clean the injector ports, though this has been shown to have little to no effect on carbon build-up on the intake valves.

#19

Audi has not yet acknowledged the extent of the carbon build-up problem. There is a letter that has been created by a forum member to Audi in this thread:

Official Letter to Audi of America Executive Vice President...Thoughts?

Publikasjonsnummer US6786433 B2

Publikasjonstype Tildeling

Søknadsnummer US 10/111,249

PCT-nummer PCT/DE2001/002710

Publiseringsdato 7. sep 2004

Arkivdato 19. jul 2001

Prioritetsdato 4. aug 2000

Gebyrstatus Forfalt

Også publisert som CN1237268C, 8 flere »

Oppfinnere Martin Maier, Joerg Heyse

Opprinnelig patentinnehaver Robert Bosch Gmbh

Eksporter sitat BiBTeX, EndNote, RefMan

Patentsiteringer (5), Klassifiseringer (26), Juridisk aktivitet (4)

Eksterne linker: USPTO, USPTO-tildeling, Espacenet

BACKGROUND INFORMATIONDuring operation of an engine, a problem generally occurs in the case of direct injection of a fuel into the combustion chamber of an internal combustion engine, particularly in the case of direct gasoline injection or the injection of diesel fuel, that the downstream tip of the injection valve projecting into the combustion chamber is coked by fuel deposits or that soot particles formed in the flame front are deposited on the valve tip. Therefore, in the conventional arrangement of injection valves projecting into the combustion chamber, there is the danger during its lifetime of a negative influence on the spray parameter (e.g., static flow quantity, spray angle, drop size, skeining) that can lead to operational disturbances of the internal combustion engine or to a malfunction of the injection valve.

And from VW engineering:

"Gasoline engines with direct injection of the fuel into the combustion chamber, i.e., not into the intake port, suffer especially from the problem of the formation of carbon deposits on components. Carbon deposits form especially in the neck region of intake valves. A more exact analysis of how these carbon deposits form leads to the following result: Oil and fuel constituents first form a sticky coating on the components. These constituents are chiefly long-chain and branched-chain hydrocarbons, i.e., the low-volatility components of oil and fuel. Aromatic compounds adhere especially well. This sticky base coating serves as a base for the deposition of soot particles. This results in a porous surface, in which oil and fuel particles in turn become embedded. This process is a circular process, by which the coating thickness of the carbon deposits continuously increases. Especially in the area of the intake valves, the deposits originate from blowby gases and from internal and external exhaust gas recirculation, and in this process, the blowby gasses and the recirculated exhaust gas come into direct contact with the intake valve.

Especially in the area of the neck of the intake valves, excessive carbon deposits have extremely negative effects for the following reasons: In the case of Otto direct injectors, the successful ignition of the stratified charge depends to a great extent on the correct development of the internal cylinder flow, which ensures reliable transport of the injected fuel to the spark plug to guarantee reliable ignition at the spark plug. However, a coating of carbon deposits in the neck region of the intake valve may interfere so strongly with the tumble flow that ignition failures may occur there as a result. Under certain circumstances, however, ignition failures can lead to irreversible damage of a catalytic converter installed in the exhaust gas tract for purifying the exhaust gas. Furthermore, the coating of carbon deposits in the neck region of the intake valve causes flow resistance, which can lead to significant performance losses due to insufficient cylinder filling, especially in the upper load and speed range of the internal combustion engine. In addition, the carbon deposits in the neck region of the intake valve may prevent correct valve closing, which leads to compression losses and thus sporadic ignition failures. This in turn could irreversibly damage the catalytic converter. There is the potential for small particles to break away from the coating of carbon deposits in the neck region of the intake valve and get into the catalytic converter. These hot particles may then cause secondary reaction and corresponding local damage of the catalytic converter. For example, a hole may be burned in the structure of the catalytic converter.

Globular deposits are found especially on the valve stem downstream from a partition plate in the intake port. Due to the dripping of high-boiling hydrocarbons from the partition plate towards the valve neck or valve stem, globular carbon deposits eventually form there by the sequence of events explained above. These deposits on the valve stem can result in flow deficits due to undesired swirling and turbulent flow around the globular carbon deposits. This may persistently interfere with the formation of stable tumble flow from cycle to cycle.

A possible solution would be to keep these sources of deposits away, for example, from the intake valve, by completely eliminating exhaust gas recirculation and the introduction of blowby gases into the intake port. However with the combustion behavior of modern reciprocating internal combustion engines, at least external exhaust gas recirculation and the introduction of blowby gases into the intake port are absolutely necessary for reasons of emission control and fuel consumption, so that this approach is not possible.

And from the site AutoGuide.com:

It’s the next generation of fuel injection, which replaced the carburetor somewhere back in the ‘80s. By result of squirting fuel right into the individual cylinder, the engine gets a higher quality of combustion and an increase in combustion efficiency. This means that a smaller engine with direct-injection can make as much power as a bigger engine without direct injection. By precisely timing and placing the injection of the fuel into the cylinder, engineers have managed to ensure a more efficient combustion. Therefore, it pollutes less too.

NEW TECH, NEW PROBLEMS?

However, direct injection isn’t without its critics. “There is a process of getting the technology to not only work but to be durable and cost effective,” Says Brauer. “The latter always takes time when a new technology first enters mainstream production.”

There are many longevity concerns with direct injection equipped engines. For example, the high pressure injection used in these engines causes a lot of stress on the fuel pumps. Regular fuel pumps in non-direct injected applications operate at much lower pressure than the high-pressure fuel pumps in direct-injected power-plants. The difference is in thousands of PSI.

Some high-pressure fuel pumps, like those used with BMW’s twin-turbo direct injection engine in the 2007-2010 335i, the 2008–2010 135i, 535i and X6 xDrive35i, as well as the 2009–2010 Z4 Roadster sDrive35i have been known to fail prematurely.

Another problem with direct injection is with ethanol fuel. Ethanol is known to speed up the corrosion rate of some metals that are used in an engine. With the higher pressure of a direct injection engine, and thanks to the fuel injector being exposed to in-cylinder explosions, there’s a higher chance of a problem or failure. Because of this, it’s more important to use higher quality fuels.

Finally, the biggest concern with direct-injection technology is with carbon buildup. In a direct injection engine, oil droplets tend to get ‘baked’ on the valve. Carbon buildup can create a lot of headaches in the long-term, with build-up being bad enough to make extra noise during operation and damage the engine. At the very least it can reduce fuel mileage, and affect performance.

Official Letter to Audi of America Executive Vice President...Thoughts?

Publikasjonsnummer US6786433 B2

Publikasjonstype Tildeling

Søknadsnummer US 10/111,249

PCT-nummer PCT/DE2001/002710

Publiseringsdato 7. sep 2004

Arkivdato 19. jul 2001

Prioritetsdato 4. aug 2000

Gebyrstatus Forfalt

Også publisert som CN1237268C, 8 flere »

Oppfinnere Martin Maier, Joerg Heyse

Opprinnelig patentinnehaver Robert Bosch Gmbh

Eksporter sitat BiBTeX, EndNote, RefMan

Patentsiteringer (5), Klassifiseringer (26), Juridisk aktivitet (4)

Eksterne linker: USPTO, USPTO-tildeling, Espacenet

BACKGROUND INFORMATIONDuring operation of an engine, a problem generally occurs in the case of direct injection of a fuel into the combustion chamber of an internal combustion engine, particularly in the case of direct gasoline injection or the injection of diesel fuel, that the downstream tip of the injection valve projecting into the combustion chamber is coked by fuel deposits or that soot particles formed in the flame front are deposited on the valve tip. Therefore, in the conventional arrangement of injection valves projecting into the combustion chamber, there is the danger during its lifetime of a negative influence on the spray parameter (e.g., static flow quantity, spray angle, drop size, skeining) that can lead to operational disturbances of the internal combustion engine or to a malfunction of the injection valve.

And from VW engineering:

"Gasoline engines with direct injection of the fuel into the combustion chamber, i.e., not into the intake port, suffer especially from the problem of the formation of carbon deposits on components. Carbon deposits form especially in the neck region of intake valves. A more exact analysis of how these carbon deposits form leads to the following result: Oil and fuel constituents first form a sticky coating on the components. These constituents are chiefly long-chain and branched-chain hydrocarbons, i.e., the low-volatility components of oil and fuel. Aromatic compounds adhere especially well. This sticky base coating serves as a base for the deposition of soot particles. This results in a porous surface, in which oil and fuel particles in turn become embedded. This process is a circular process, by which the coating thickness of the carbon deposits continuously increases. Especially in the area of the intake valves, the deposits originate from blowby gases and from internal and external exhaust gas recirculation, and in this process, the blowby gasses and the recirculated exhaust gas come into direct contact with the intake valve.

Especially in the area of the neck of the intake valves, excessive carbon deposits have extremely negative effects for the following reasons: In the case of Otto direct injectors, the successful ignition of the stratified charge depends to a great extent on the correct development of the internal cylinder flow, which ensures reliable transport of the injected fuel to the spark plug to guarantee reliable ignition at the spark plug. However, a coating of carbon deposits in the neck region of the intake valve may interfere so strongly with the tumble flow that ignition failures may occur there as a result. Under certain circumstances, however, ignition failures can lead to irreversible damage of a catalytic converter installed in the exhaust gas tract for purifying the exhaust gas. Furthermore, the coating of carbon deposits in the neck region of the intake valve causes flow resistance, which can lead to significant performance losses due to insufficient cylinder filling, especially in the upper load and speed range of the internal combustion engine. In addition, the carbon deposits in the neck region of the intake valve may prevent correct valve closing, which leads to compression losses and thus sporadic ignition failures. This in turn could irreversibly damage the catalytic converter. There is the potential for small particles to break away from the coating of carbon deposits in the neck region of the intake valve and get into the catalytic converter. These hot particles may then cause secondary reaction and corresponding local damage of the catalytic converter. For example, a hole may be burned in the structure of the catalytic converter.

Globular deposits are found especially on the valve stem downstream from a partition plate in the intake port. Due to the dripping of high-boiling hydrocarbons from the partition plate towards the valve neck or valve stem, globular carbon deposits eventually form there by the sequence of events explained above. These deposits on the valve stem can result in flow deficits due to undesired swirling and turbulent flow around the globular carbon deposits. This may persistently interfere with the formation of stable tumble flow from cycle to cycle.

A possible solution would be to keep these sources of deposits away, for example, from the intake valve, by completely eliminating exhaust gas recirculation and the introduction of blowby gases into the intake port. However with the combustion behavior of modern reciprocating internal combustion engines, at least external exhaust gas recirculation and the introduction of blowby gases into the intake port are absolutely necessary for reasons of emission control and fuel consumption, so that this approach is not possible.

And from the site AutoGuide.com:

It’s the next generation of fuel injection, which replaced the carburetor somewhere back in the ‘80s. By result of squirting fuel right into the individual cylinder, the engine gets a higher quality of combustion and an increase in combustion efficiency. This means that a smaller engine with direct-injection can make as much power as a bigger engine without direct injection. By precisely timing and placing the injection of the fuel into the cylinder, engineers have managed to ensure a more efficient combustion. Therefore, it pollutes less too.

NEW TECH, NEW PROBLEMS?

However, direct injection isn’t without its critics. “There is a process of getting the technology to not only work but to be durable and cost effective,” Says Brauer. “The latter always takes time when a new technology first enters mainstream production.”

There are many longevity concerns with direct injection equipped engines. For example, the high pressure injection used in these engines causes a lot of stress on the fuel pumps. Regular fuel pumps in non-direct injected applications operate at much lower pressure than the high-pressure fuel pumps in direct-injected power-plants. The difference is in thousands of PSI.

Some high-pressure fuel pumps, like those used with BMW’s twin-turbo direct injection engine in the 2007-2010 335i, the 2008–2010 135i, 535i and X6 xDrive35i, as well as the 2009–2010 Z4 Roadster sDrive35i have been known to fail prematurely.

Another problem with direct injection is with ethanol fuel. Ethanol is known to speed up the corrosion rate of some metals that are used in an engine. With the higher pressure of a direct injection engine, and thanks to the fuel injector being exposed to in-cylinder explosions, there’s a higher chance of a problem or failure. Because of this, it’s more important to use higher quality fuels.

Finally, the biggest concern with direct-injection technology is with carbon buildup. In a direct injection engine, oil droplets tend to get ‘baked’ on the valve. Carbon buildup can create a lot of headaches in the long-term, with build-up being bad enough to make extra noise during operation and damage the engine. At the very least it can reduce fuel mileage, and affect performance.

#20

Direct Injection Could Be Maintenance Nightmare

June 29th, 2011Goto commentsLeave a comment

Cars with direct injection: Trouble waiting to happen?

Writers across the automotive blogosphere are guilty of using the words “direct injected” as an adjective meant to give some punch to the description of a new engine. I am no exception:

Buick will offer a no-extra-cost 3.6-liter direct-injected V6…

But what does “direct injected” really mean? Many readers of this blog are enthusiasts and know exactly what the term describes, but for others, it’s just more techie jargon that sounds cool in front of the term “V6.”

I’ll briefly describe what it means, but more importantly, ask if direct injection is the savior some automakers believe. Some evidence is beginning to crop up that could translate to future maintenance disasters.

First, for the uninitiated:

A direct-injected engine injects pressurized fuel directly into the combustion chamber, rather than into an intake manifold where it gets mixed with air and then enters the combustion chamber.

The results of direct injection are improved fuel economy and cleaner emissions due to a leaner fuel burn, which Ford, GM, Volkswagen, Hyundai and others love to tout in advertisements and press releases.

The problem, though, is pretty dirty.

Auto Observer reports that the issue lies in the tendency of direct-injected engines to build up a layer of carbon around the intake valves that can significantly affect the performance and economy of the engines over time. The dirty grime builds up in a DI engine because, unlike a port-injected engine, there is no constant spray of fuel to keep the deposits washed off the valves.

The repair can be quite expensive, though some guys at a BMW forumswear that “giving the car a good flogging” once in a while burns the deposits off. Maybe… but that’s probably not a substitute for dropping the bucks and having the valves cleaned.

Volkswagen has known about the DI problem for quite some time, saying in a patent application that the carbon deposits can have extremely negative effects on performance.

Owners of Cadillac’s direct-injected V6 have also reportedly started to complain, though GM remains adamant that it has engineered around the problem.

Whether the problem exists only in the Caddy owners’ heads or not, it’s becoming quite clear that direct injection still has some hurdles to clear before automakers roll out the technology across the board.

This article quotes auto maker PR reps claiming "we have no issues with this problem" (they all claim the same) but as the dyno graphs, etc. show the auto makers PR spin has been shown to un-true:

Direct Injection Fouls Some Early Adopters

By AUTOOBSERVER STAFF June 15, 2011

Comments (4)

This image has been resized. Click this bar to view the full image. The original image is sized 620x347.

In their efforts to wring more power and efficiency from the internal combustion engine, automakers are increasingly turning to gasoline direct-injection technology – also known as GDI or DI. Originally developed to produce more economical and quieter combustion for diesel engines, DI is inherently more efficient and helps generate more power than port injection. And advances in engineering and engine management, fueled by fierce industry competition and consumer demand, are making DI technology more cost-effective than ever for manufacturers: gasoline DI engines are appearing in entry-level models from Ford Motor Co., General Motors Co.’s Chevrolet and Hyundai Motors. Currently, more than 60 2011 and 2012 models in the U.S. offer DI engines as standard equipment.

But there has been a dark side to the technology: carbon build-up around intake valves that, over time, can degrade power and efficiency, eroding the bonus DI is supposed to provide. While there’s evidence that the most recent designs and technical enhancements have greatly reduced the issue, carbon buildup has been a distinct and well-documented issue in some DI engines from a variety of manufacturers over the last few years.

Known Problems

A U.S. patent application filed in 2002 by Volkswagen AG explains the DI-engine carbon-deposit dilemma this way: “Gasoline engines with direct injection of the fuel into the combustion chamber…suffer especially from the problem of the formation of carbon deposits…especially in the neck region of the intake valves.”

The document describes these deposits as a sticky coating of oil and fuel constituents that, once formed, serves as a base for further deposits, creating “a circular process, by which the coating thickness of the carbon deposits continuously increases.” Excessive carbon deposits “have extremely negative effects,” the patent application concludes, citing significant performance losses, sporadic ignition failures and, potentially, holes burned in the structure of the catalytic converter (should bits of carbon break from the valves and pass though the combustion chamber).

Ameer Haider, GM’s assistant chief engineer for V6 engines, certainly knows the problem, tellingAutoObserver, “DI engines are prone to forming oily deposits on the intake valves, unlike in port fuel-injected engines, where a constant spray of fuel into the port allows any deposits to wash away. With DI engines, the fuel gets injected directly into the combustion chamber, so there isn't a chance for the deposits to wash away. Typically, deposits form when soot – which is an end-product of combustion – adheres to the valve stem.”

The main purpose of VW’s patent application was to propose a fix for DI engine carbon deposits: specifically, applying “a catalytic surface” to the engine valves that “counteracts the formation of carbon deposits.” But nearly 10 years later, there’s ample evidence that this and other potential solutions have failed.

June 29th, 2011Goto commentsLeave a comment

Cars with direct injection: Trouble waiting to happen?

Writers across the automotive blogosphere are guilty of using the words “direct injected” as an adjective meant to give some punch to the description of a new engine. I am no exception:

Buick will offer a no-extra-cost 3.6-liter direct-injected V6…

But what does “direct injected” really mean? Many readers of this blog are enthusiasts and know exactly what the term describes, but for others, it’s just more techie jargon that sounds cool in front of the term “V6.”

I’ll briefly describe what it means, but more importantly, ask if direct injection is the savior some automakers believe. Some evidence is beginning to crop up that could translate to future maintenance disasters.

First, for the uninitiated:

A direct-injected engine injects pressurized fuel directly into the combustion chamber, rather than into an intake manifold where it gets mixed with air and then enters the combustion chamber.

The results of direct injection are improved fuel economy and cleaner emissions due to a leaner fuel burn, which Ford, GM, Volkswagen, Hyundai and others love to tout in advertisements and press releases.

The problem, though, is pretty dirty.

Auto Observer reports that the issue lies in the tendency of direct-injected engines to build up a layer of carbon around the intake valves that can significantly affect the performance and economy of the engines over time. The dirty grime builds up in a DI engine because, unlike a port-injected engine, there is no constant spray of fuel to keep the deposits washed off the valves.

The repair can be quite expensive, though some guys at a BMW forumswear that “giving the car a good flogging” once in a while burns the deposits off. Maybe… but that’s probably not a substitute for dropping the bucks and having the valves cleaned.

Volkswagen has known about the DI problem for quite some time, saying in a patent application that the carbon deposits can have extremely negative effects on performance.

Owners of Cadillac’s direct-injected V6 have also reportedly started to complain, though GM remains adamant that it has engineered around the problem.

Whether the problem exists only in the Caddy owners’ heads or not, it’s becoming quite clear that direct injection still has some hurdles to clear before automakers roll out the technology across the board.

This article quotes auto maker PR reps claiming "we have no issues with this problem" (they all claim the same) but as the dyno graphs, etc. show the auto makers PR spin has been shown to un-true:

Direct Injection Fouls Some Early Adopters

By AUTOOBSERVER STAFF June 15, 2011

Comments (4)

This image has been resized. Click this bar to view the full image. The original image is sized 620x347.

In their efforts to wring more power and efficiency from the internal combustion engine, automakers are increasingly turning to gasoline direct-injection technology – also known as GDI or DI. Originally developed to produce more economical and quieter combustion for diesel engines, DI is inherently more efficient and helps generate more power than port injection. And advances in engineering and engine management, fueled by fierce industry competition and consumer demand, are making DI technology more cost-effective than ever for manufacturers: gasoline DI engines are appearing in entry-level models from Ford Motor Co., General Motors Co.’s Chevrolet and Hyundai Motors. Currently, more than 60 2011 and 2012 models in the U.S. offer DI engines as standard equipment.

But there has been a dark side to the technology: carbon build-up around intake valves that, over time, can degrade power and efficiency, eroding the bonus DI is supposed to provide. While there’s evidence that the most recent designs and technical enhancements have greatly reduced the issue, carbon buildup has been a distinct and well-documented issue in some DI engines from a variety of manufacturers over the last few years.

Known Problems

A U.S. patent application filed in 2002 by Volkswagen AG explains the DI-engine carbon-deposit dilemma this way: “Gasoline engines with direct injection of the fuel into the combustion chamber…suffer especially from the problem of the formation of carbon deposits…especially in the neck region of the intake valves.”

The document describes these deposits as a sticky coating of oil and fuel constituents that, once formed, serves as a base for further deposits, creating “a circular process, by which the coating thickness of the carbon deposits continuously increases.” Excessive carbon deposits “have extremely negative effects,” the patent application concludes, citing significant performance losses, sporadic ignition failures and, potentially, holes burned in the structure of the catalytic converter (should bits of carbon break from the valves and pass though the combustion chamber).

Ameer Haider, GM’s assistant chief engineer for V6 engines, certainly knows the problem, tellingAutoObserver, “DI engines are prone to forming oily deposits on the intake valves, unlike in port fuel-injected engines, where a constant spray of fuel into the port allows any deposits to wash away. With DI engines, the fuel gets injected directly into the combustion chamber, so there isn't a chance for the deposits to wash away. Typically, deposits form when soot – which is an end-product of combustion – adheres to the valve stem.”

The main purpose of VW’s patent application was to propose a fix for DI engine carbon deposits: specifically, applying “a catalytic surface” to the engine valves that “counteracts the formation of carbon deposits.” But nearly 10 years later, there’s ample evidence that this and other potential solutions have failed.