Another Custom Center Console / Sub Box

#12

#14

Those terminals as long as he used sealant are perfectly fine.

I usually dont use screws and liquid nails is a no no in car audio. If you use wood glue the bond will be as secure as using screws. I screwed me last box together just because I didnt have an wood glue handy but make sure with MDF to drill pilot holes so the wood doesnt split.

Ok Im done with my lesson today lol.

I usually dont use screws and liquid nails is a no no in car audio. If you use wood glue the bond will be as secure as using screws. I screwed me last box together just because I didnt have an wood glue handy but make sure with MDF to drill pilot holes so the wood doesnt split.

Ok Im done with my lesson today lol.

#15

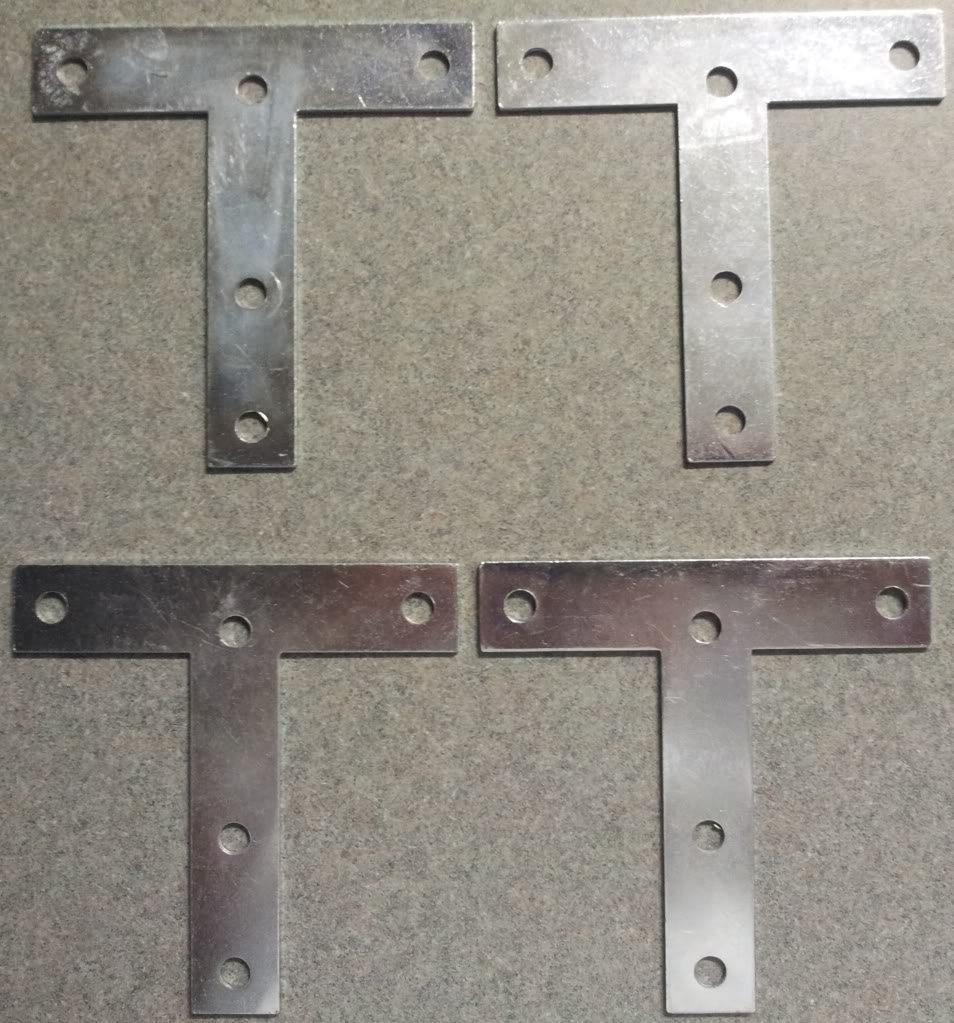

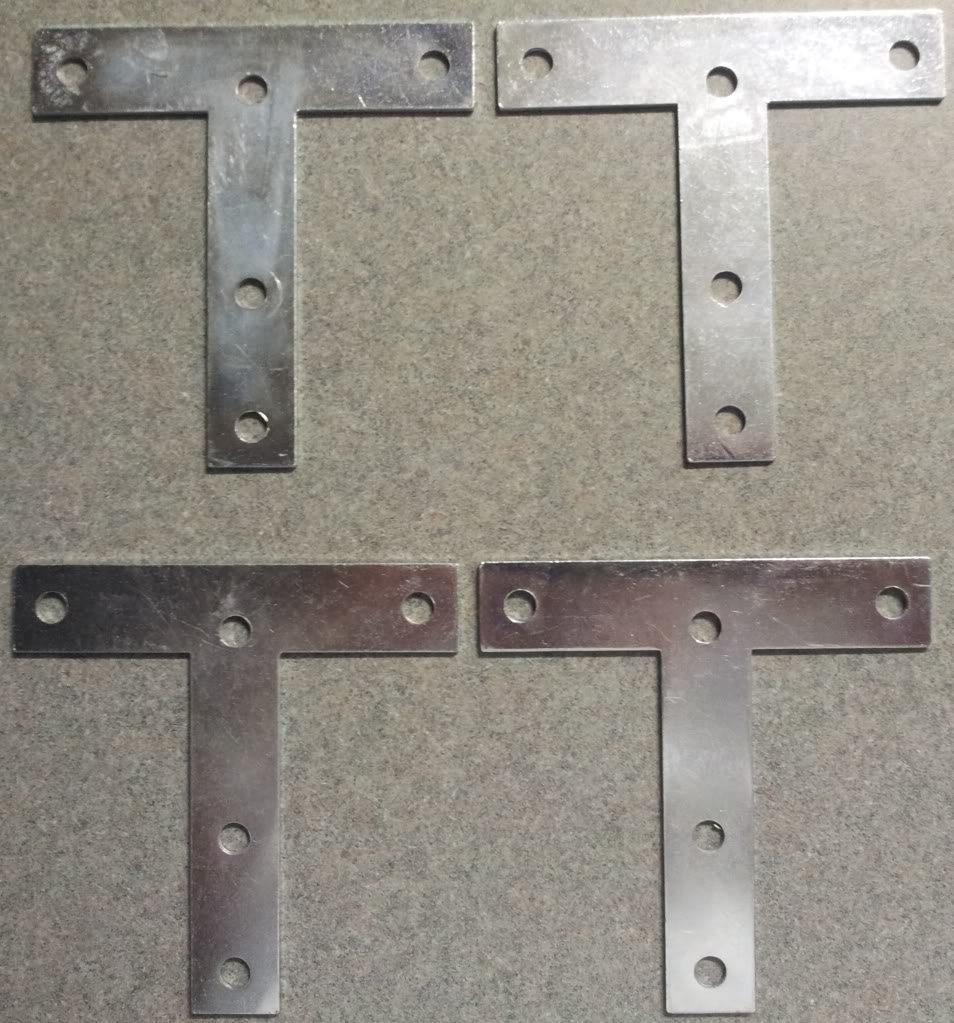

I had a few hours today to work on the mounting setup of the center console, before my power went out (bad storm). Tons of measuring and drilling today! I also made a trip to my local home improvement store. I picked of tons of stuff (brackets, bolts, nuts and washers). I plan on reusing my factory mounting holes / points for the factory console lid. I found some chrome replacement bolts (because the factory bolts.. omg!)

I measured and bent brackets at a 90 degree angle but I was not 100% sure that the 90 degree bend didn't somehow compromise the integrity of the metal. So, I welded / reinforced the 90 degree angle and filed it down a bit. Now I KNOW that will hold! After I test fit everything, the metal parts will be dropped off in the morning to my local powder coater and the console will be dropped off at my local upholstery shop. It's getting close!

I measured and bent brackets at a 90 degree angle but I was not 100% sure that the 90 degree bend didn't somehow compromise the integrity of the metal. So, I welded / reinforced the 90 degree angle and filed it down a bit. Now I KNOW that will hold! After I test fit everything, the metal parts will be dropped off in the morning to my local powder coater and the console will be dropped off at my local upholstery shop. It's getting close!

#16

How do I know??? I'm glad you asked.. haha. Obviously, looking at my screen name, you can guess what I do for a living. Well, among the few trades that I have knowledge of, I used to install TONS of electronics in "bait cars". I've hidden camera's, microphones, infared floods, wiring, brain modules, GPS units, etc.. I took 6 pieces of plastic. I glued each piece together with Omni-Stick. In the middle of the plastic "box", I had paper with black lines on it. It works wonders to "test" for moisture. I submerged the glued box under water for 6 weeks. At the end of 6 weeks, I had to cut the plastic box open to remove the paper.. not a single sign of moisture (if it can withstand a prolonged exposure to being under water and it still has an air tight seal for a hidden video camera, it can seal a speaker terminal post in a sub box).. hehe.

Last edited by officermartinez; 06-06-2012 at 07:19 PM.

#17

Those terminals as long as he used sealant are perfectly fine.

I usually dont use screws and liquid nails is a no no in car audio. If you use wood glue the bond will be as secure as using screws. I screwed me last box together just because I didnt have an wood glue handy but make sure with MDF to drill pilot holes so the wood doesnt split.

Ok Im done with my lesson today lol.

I usually dont use screws and liquid nails is a no no in car audio. If you use wood glue the bond will be as secure as using screws. I screwed me last box together just because I didnt have an wood glue handy but make sure with MDF to drill pilot holes so the wood doesnt split.

Ok Im done with my lesson today lol.

#18

I've got this setup on my dash but the cup holder is coming out. I spill tons of coffee or my cold drinks "sweat" and it would land on my newly upsholstered center console box..

So, I went down to a local Ford Dealer and ordered this ($52 dollars ugh) :

Problem solved.

Here's a rough view of the console mounting solution. Don't worry, everything will look nice and "purdy" when I send the metal off to be powder coated..

So, I went down to a local Ford Dealer and ordered this ($52 dollars ugh) :

Problem solved.

Here's a rough view of the console mounting solution. Don't worry, everything will look nice and "purdy" when I send the metal off to be powder coated..

#20

Senior Member

Cool project!

Per the screw and glue comments... I used course thread drywall screws without any problem. Pre-drill the holes. With glue, I recommend not using it. Glue hardens and has the potential to vibrate. Use silicon instead. It'll hold joints together (with screws) just fine, and it'll stay flexible in so that, it won't ever vibrate.

My two cents... Probably not worth even that.

Per the screw and glue comments... I used course thread drywall screws without any problem. Pre-drill the holes. With glue, I recommend not using it. Glue hardens and has the potential to vibrate. Use silicon instead. It'll hold joints together (with screws) just fine, and it'll stay flexible in so that, it won't ever vibrate.

My two cents... Probably not worth even that.