How to pump gas OUT of pressure side (for chainsaws, ATV etc)

#61

I prefer to research a solution that uses the gas guage on my dash, the one fuel filler on the driverside of my truck, and cost of only a few fittings and some research time. Up to now I did not anticipate the aggravation of explaining it over and over again.

I don't understand why my decision needs to be debated. The assistance I need is with the truck fuel system. It's a complicated system and to get this right I would very much prefer to discuss this system with members who are familiar with it, rather than go back and forth on unrelated subjects with those who are afraid of it, and in some cases know NOTHING. And probably never carry anything in their truck either.

Or at least discuss it with those who are interested in success of a project rather than failing it because they are not interested.

It disappoints me that this kind of technical discussion can't be conducted on this F150forum. Can anybody suggest another F150 forum where the members participate not just entertain themselves? Jeeez

Last edited by Fyaboy; 12-18-2014 at 05:33 PM.

#62

Senior Member

It seems as though people are answering your question, just not how you WANT it answered. This forum is the most useful F150 forum you will find. Just because you are not getting the answer you WANT doesn't mean you are not getting your answer. There have been many alternatives to your method, but you are too hard headed to listen to what more experienced (that's what you are asking for right) people have to say.

The following users liked this post:

BCMIF150 (12-18-2014)

#63

Senior Member

I have done this with my 89 jeep and 2000 ranger, haven't looked to see if the fuel rail would work for connections....its slow and you may lose to much fuel psi with the bleed port and stall the engine running.. but for small amounts of fuel it would work and not to bad on the expense....

#64

Thanks Steve.

Pretty much starts to get useful if 2 gpm is available. 2 gpm would fill a 5gal can in 2.5 minutes. At this point I'm doubting that even 1gpm is available (at ~0psi).

Pretty much starts to get useful if 2 gpm is available. 2 gpm would fill a 5gal can in 2.5 minutes. At this point I'm doubting that even 1gpm is available (at ~0psi).

#65

Senior Member

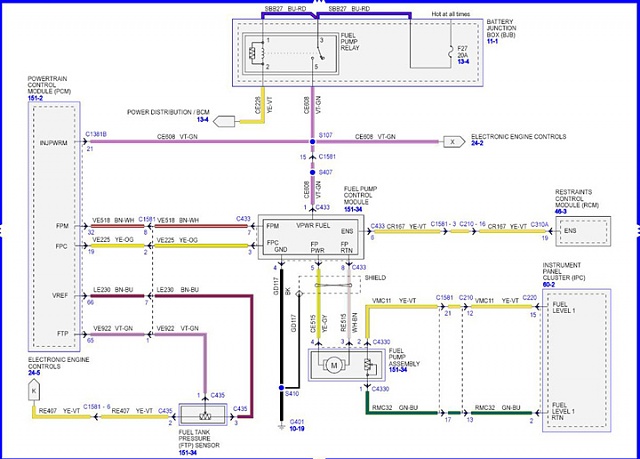

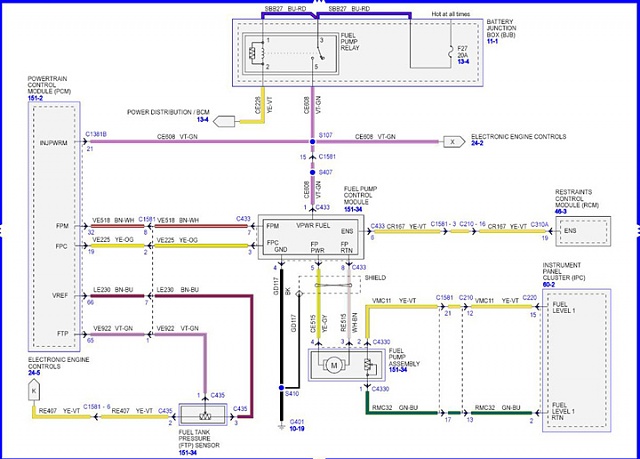

These aren't like the old return style systems where the pump was continuously running with a pressure regulator in line to manage the pressure at the rail. The pressure is managed by the driver signal to the pump which modulates the voltage to the pump through the FPDM.

(Again, these are assumptions based off of troubleshooting the system. I don't have access to their ladder logic and schematics)

#66

If you think he is trolling, Stay out of the thread. If you want to troll him, Stay out of the thread.

Help the guy, or move on.

If you come to post meme's, Stay out of the thread.

Help the guy, or move on.

If you come to post meme's, Stay out of the thread.

The following users liked this post:

Fyaboy (12-19-2014)

#67

Senior Member

I think it is a great idea with useful function but must be done properly to be safe.

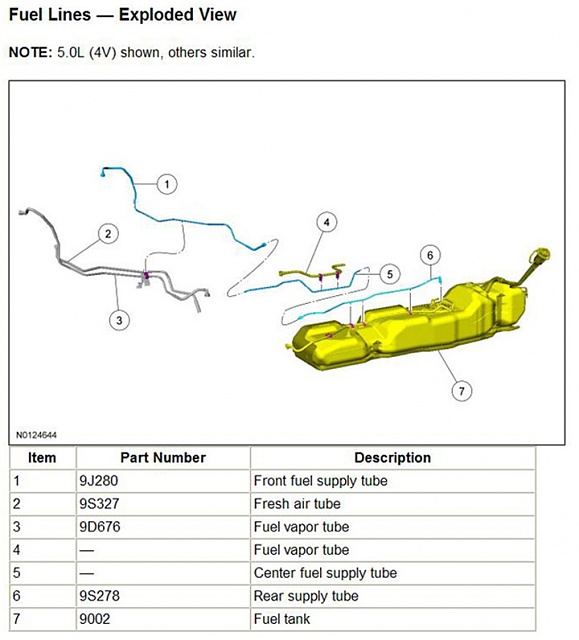

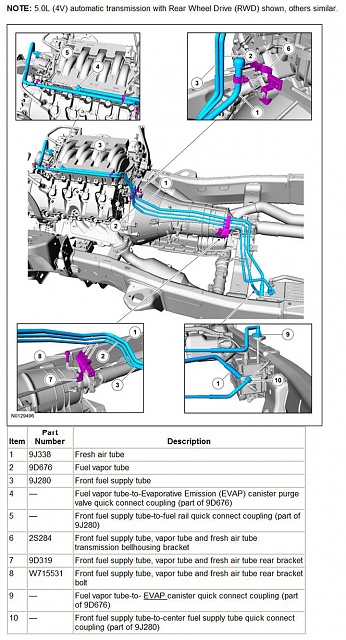

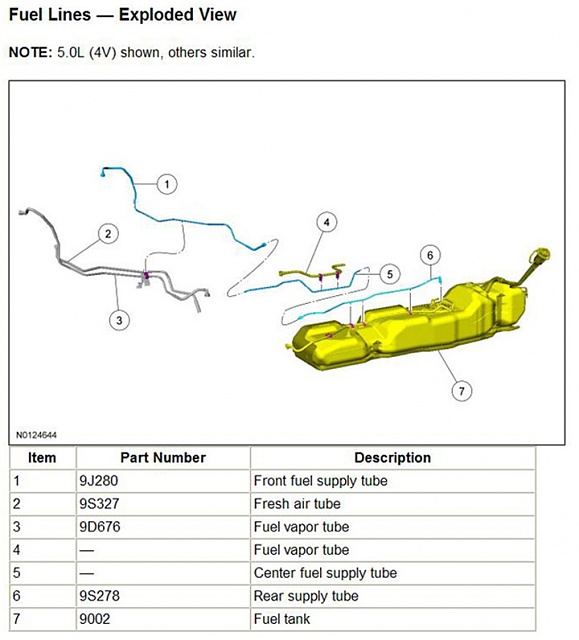

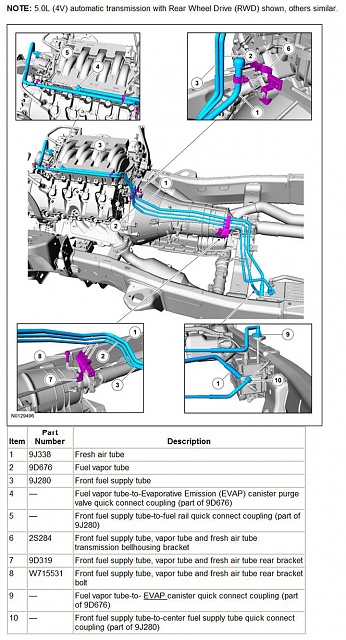

I'd be inclined to use a "3-way" valve to divert the flow from engine to fill function. That way you can't forget to turn it back to run position because the engine won't run. The hardest part will be plumbing because all connections are QD. You'll either have to adapt to them or cut lines. Cutting lines might be okay as long as you do it properly. Go buy a replacement tube and try it.

You'll have to "hot wire" the pump to get it to run. I'd have to hook up the o-scope to know for sure but I'm guessing the YE-GY wire is constant power and the WH-BN is modulated ground so grounding the WH-BN wire should run the pump full speed. But that might be totally wrong so it may be safer to hijack both wires. You could use a DPDT ON-NONE-(ON) to totally hijack the pump. Obviously the constant on is "engine run" position and the momentary on is the "fill" position.

I'd be inclined to use a "3-way" valve to divert the flow from engine to fill function. That way you can't forget to turn it back to run position because the engine won't run. The hardest part will be plumbing because all connections are QD. You'll either have to adapt to them or cut lines. Cutting lines might be okay as long as you do it properly. Go buy a replacement tube and try it.

You'll have to "hot wire" the pump to get it to run. I'd have to hook up the o-scope to know for sure but I'm guessing the YE-GY wire is constant power and the WH-BN is modulated ground so grounding the WH-BN wire should run the pump full speed. But that might be totally wrong so it may be safer to hijack both wires. You could use a DPDT ON-NONE-(ON) to totally hijack the pump. Obviously the constant on is "engine run" position and the momentary on is the "fill" position.

Last edited by depami; 12-19-2014 at 01:28 AM.

The following users liked this post:

Fyaboy (12-19-2014)

#68

Senior Member

DePami,

You wouldn't happen to have the flow rate of the pump handy, would you? That would help the OP figure out if modifying the fuel lines would be worth it.

I tried to find it, but came up with bubkus.

You wouldn't happen to have the flow rate of the pump handy, would you? That would help the OP figure out if modifying the fuel lines would be worth it.

I tried to find it, but came up with bubkus.

#69

Senior Member

I couldn't find it either but I didn't spend a lot of time searching. I'll look again.

The following users liked this post:

Fyaboy (12-19-2014)