Alternator charge cable

#31

Member

Join Date: Jan 2018

Location: Memphis, TN, Earth, Milky Way

Posts: 11,256

Received 1,731 Likes

on

1,487 Posts

Yeah, that's my point. If there's ever a problem at that frame bolt, you'll lose grounding to everything but the body. The block's grounding is dependent on 3 fasteners: the battery terminal, the frame bolt, AND the block bolt. Better to have only 2 critical connections: terminal & block.But everything is new & clean right now. When it gets a few thousand miles on it, and you've forgotten about this, that's when it'll creep up on you, and you'll wonder why so many electrical problems have appeared at once. Now's the time to reduce the potential for future problems. It's just one ring terminal being moved from the frame to the block. Electrical grease would make all these connections nearly worry-free.

(phone app link)

(phone app link)

The following users liked this post:

BLDTruth (03-18-2018)

#32

Senior Member

Thread Starter

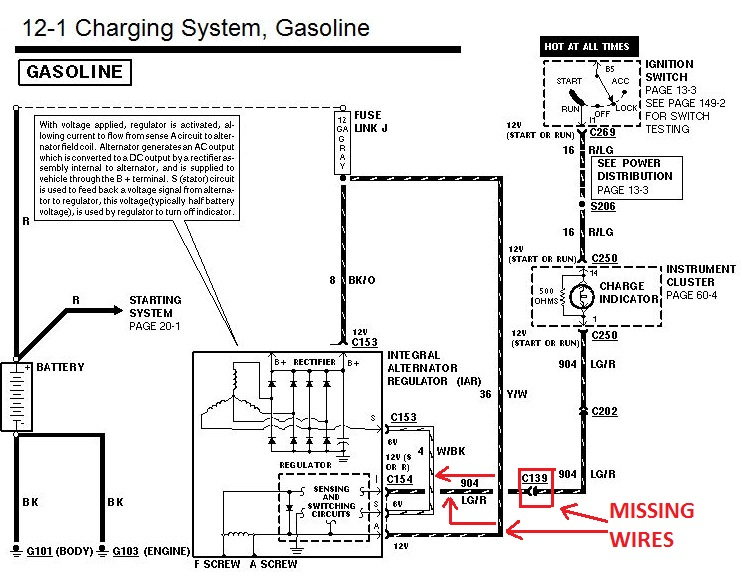

I'm revisiting this because I don't want to order another charge cable, and want to use my 4 gauge charge cable with 8 gauge fusible link. So I need to hack into the factory charge cable harness a little bit.

I think the solution is to cut wire 36 (the wire going into the A side of the alternator connector) and then just run that directly from the alternator plug to the alternator charge terminal via a small jumper wire with another ring terminal. I would also need to pull wire 904 out of the factory harness and makes sure it remains connected at C139 (the wire coming out of the I side of the alternator connector).

Thoughts?

I think the solution is to cut wire 36 (the wire going into the A side of the alternator connector) and then just run that directly from the alternator plug to the alternator charge terminal via a small jumper wire with another ring terminal. I would also need to pull wire 904 out of the factory harness and makes sure it remains connected at C139 (the wire coming out of the I side of the alternator connector).

Thoughts?

#33

Member

Join Date: Jan 2018

Location: Memphis, TN, Earth, Milky Way

Posts: 11,256

Received 1,731 Likes

on

1,487 Posts

You're talking about dismantling a good wiring harness to fix one that wasn't built right, and won't make your truck run better. I don't get it, but good luck.

The A wire is not simply a voltage connection to any nominal B+ circuit; its purpose is to send actual battery voltage (or as close as possible) to the VR. That's why the factory routing goes to the far end of the charge cable, close to the (+) battery post, instead of the short path to C153.

The A wire is not simply a voltage connection to any nominal B+ circuit; its purpose is to send actual battery voltage (or as close as possible) to the VR. That's why the factory routing goes to the far end of the charge cable, close to the (+) battery post, instead of the short path to C153.

#34

Senior Member

Thread Starter

You're talking about dismantling a good wiring harness to fix one that wasn't built right, and won't make your truck run better. I don't get it, but good luck.

The A wire is not simply a voltage connection to any nominal B+ circuit; its purpose is to send actual battery voltage (or as close as possible) to the VR. That's why the factory routing goes to the far end of the charge cable, close to the (+) battery post, instead of the short path to C153.

The A wire is not simply a voltage connection to any nominal B+ circuit; its purpose is to send actual battery voltage (or as close as possible) to the VR. That's why the factory routing goes to the far end of the charge cable, close to the (+) battery post, instead of the short path to C153.

So based on your comment, would it be better to run the "A" wire from the alternator plug all the way back to the starter relay (or battery) to get a more "true" reading of actual battery voltage? That would be easy enough to do and I can tuck it into the loom for my new charge cable.

#35

Senior Member

iTrader: (1)

I could be wrong of course, but I don't think you're going to be getting a reading of battery voltage so much as current charging - so when the alternator is working to charge the battery back up you'll see a higher voltage registering on your gauge and when your alternator freewheels because the battery is charged up you'll see a more normal voltage.

As I've always understood it anyway.

I think you can untape your harness and replace the light charge cable with the heavier one and you should be good.

For what you want I think you should consider a dual battery setup. That requires relocating your washer/overflow bottle but that's not impossible. The battery trays and wiring are readily available in any 9th gen diesel truck (bolt-in) and the wiring is simple enough - power from one battery to the other and ground to the block.

To get a little more trick with it you can break that power wire with a constant run solenoid; which looks just like the fender relay but is designed to handle steady power (fender relays burn out if used this way).

I set the one on my old camper truck up to be activated by the alternator; so if the engine was running the batteries were connected and if the motor was off the batteries were separated. That way you could totally drain the battery with the camper and still fire the truck up with the other battery.

Also had an override switch on the dash that would operate the c/r solenoid so that if you ever killed the main starting battery you could flip the switch and the auxiliary battery would "boost" the main battery.

It's simpler than it sounds to set up and it's the kind of thing you could get into doing.

As I've always understood it anyway.

I think you can untape your harness and replace the light charge cable with the heavier one and you should be good.

For what you want I think you should consider a dual battery setup. That requires relocating your washer/overflow bottle but that's not impossible. The battery trays and wiring are readily available in any 9th gen diesel truck (bolt-in) and the wiring is simple enough - power from one battery to the other and ground to the block.

To get a little more trick with it you can break that power wire with a constant run solenoid; which looks just like the fender relay but is designed to handle steady power (fender relays burn out if used this way).

I set the one on my old camper truck up to be activated by the alternator; so if the engine was running the batteries were connected and if the motor was off the batteries were separated. That way you could totally drain the battery with the camper and still fire the truck up with the other battery.

Also had an override switch on the dash that would operate the c/r solenoid so that if you ever killed the main starting battery you could flip the switch and the auxiliary battery would "boost" the main battery.

It's simpler than it sounds to set up and it's the kind of thing you could get into doing.

The following users liked this post:

BLDTruth (04-16-2018)

#36

Member

Join Date: Jan 2018

Location: Memphis, TN, Earth, Milky Way

Posts: 11,256

Received 1,731 Likes

on

1,487 Posts

I don't think so. I think it will easily handle more than the alt can ever put out. When I built my truck last time, I added a big e-fan (~35A), electric OBA, a 1KW inverter, a winch that can pull 400A at stall, another identical battery, seat heaters, RKE, HIDs, LEDs, incandescent lights, USB power adapters... The stock charge cable (from the original 95A alt) handled the 130A's output just fine, even when it ran at peak for hours.

Those will get most of their power from the battery - the alt will try to keep the battery charged, but nothing you do will ever "pull" more current through the charge cable than the alt is trying to put out (as controlled by the VR).Those draw less current than the stock headlights, so that's a reduction.

The VR is designed to work with the A voltage coming from the charge cable's fusible link at the starter relay. Moving it closer to the battery MIGHT result in overcharging; moving it closer to the alt MIGHT result in undercharging. I'd leave it where it is (either on the stock charge cable, or on anything you build).

That would retain all the safety & functionality of the charging circuit, but it would make the heavier wire pointless. Even though the new cable could carry more current, the fusible link can't, so it would still burn out at slightly LESS current than the original would have carried. If you mean to eliminate the fusible link too, that's not safe. If you mean to increase the size of the fusible link proportionally to the new cable, that wouldn't protect the battery from a short in the alternator like the original fusible link does. It would take vastly more current to blow the bigger fusible link than the alt would draw at its most-catastrophic failure.

"Require" is a strong word - relocating the reservoirs is one possible location, but it's not the only one. Mine is inside the frame behind the t-case on a new crossmember.

(phone app link)This shows how Ford did it (w/o the control switch), and an easy modification:

(phone app link)

This shows essentially the same thing, but with some clutter:

(phone app link)

(phone app link)This shows how Ford did it (w/o the control switch), and an easy modification:

(phone app link)

This shows essentially the same thing, but with some clutter:

(phone app link)

#37

Senior Member

Thread Starter

I don't think so. I think it will easily handle more than the alt can ever put out. When I built my truck last time, I added a big e-fan (~35A), electric OBA, a 1KW inverter, a winch that can pull 400A at stall, another identical battery, seat heaters, RKE, HIDs, LEDs, incandescent lights, USB power adapters... The stock charge cable (from the original 95A alt) handled the 130A's output just fine, even when it ran at peak for hours.

Those will get most of their power from the battery - the alt will try to keep the battery charged, but nothing you do will ever "pull" more current through the charge cable than the alt is trying to put out (as controlled by the VR).

Last edited by BLDTruth; 04-17-2018 at 10:00 AM.