Last edit by: IB Advertising

DIY ABS Module Rebuild - ABS Pump Won't Shut Off - Issue Solved

#101

So this weekend I had an interesting turn of events. I was rebuilding a module that goes to a 2000 Ford F-150 XLT Lariat edition. I tested the chip and it tested bad. Ok...too easy! I replaced the chip and tested the connections...everything ok so far. I decided to test it out on my 2000 F150 off road edition and guess what happened: as soon as I started my truck up the abs light came on. I shut off the truck to find the pump running constantly. I changed out the chip again and tested. Started it up...no light...no running pump on shutdown. I started it up two more times and on the last go my abs light came on and pump was running again. I'm thinking perhaps my abs assembly is more heavy duty and not compatible with this module. Thoughts??

#102

hey Chris, sorry to here you are having fits with that unit. Have you also checked the solder joints around the relay? Webbster found cracked joints and he was having a problem of ABS light on and The pump would sometimes run for a few minutes after he shut off the truck. He resoldered those relay joints and now all is good. I posted labeled photos of the relay pins. This goes only for the 4WABS that is on the 4x4 and all wheel drive versions but as far as I know the same basic ABS unit and controller is used on all models of the F-150, Expedition and Navigator . The difference is that the program in each controller version is fine tuned to the GWVR , Wheel base , and cab type ( ie standard cab , crew or SUV body ). I have the heaviest Duty version of the F-150, The 7700 pound payload edition with the heavy frame, bigger brakes and 7 lug wheels. I tested my problem using a 4WABS module of of a 2000 Expedition. The truck worked fine but I did not trust that the program in the Expedition module would be safe for my 7700 if I was loaded up and had to use ABS in a panic brake. That was why I repaired mine ( just finished test driving it, works great ) My controller module actually has Heavy F150 in the part number label so I know its unique to the 7700 but the Expedition version functioned normally at least in basic conditions of the system.

#103

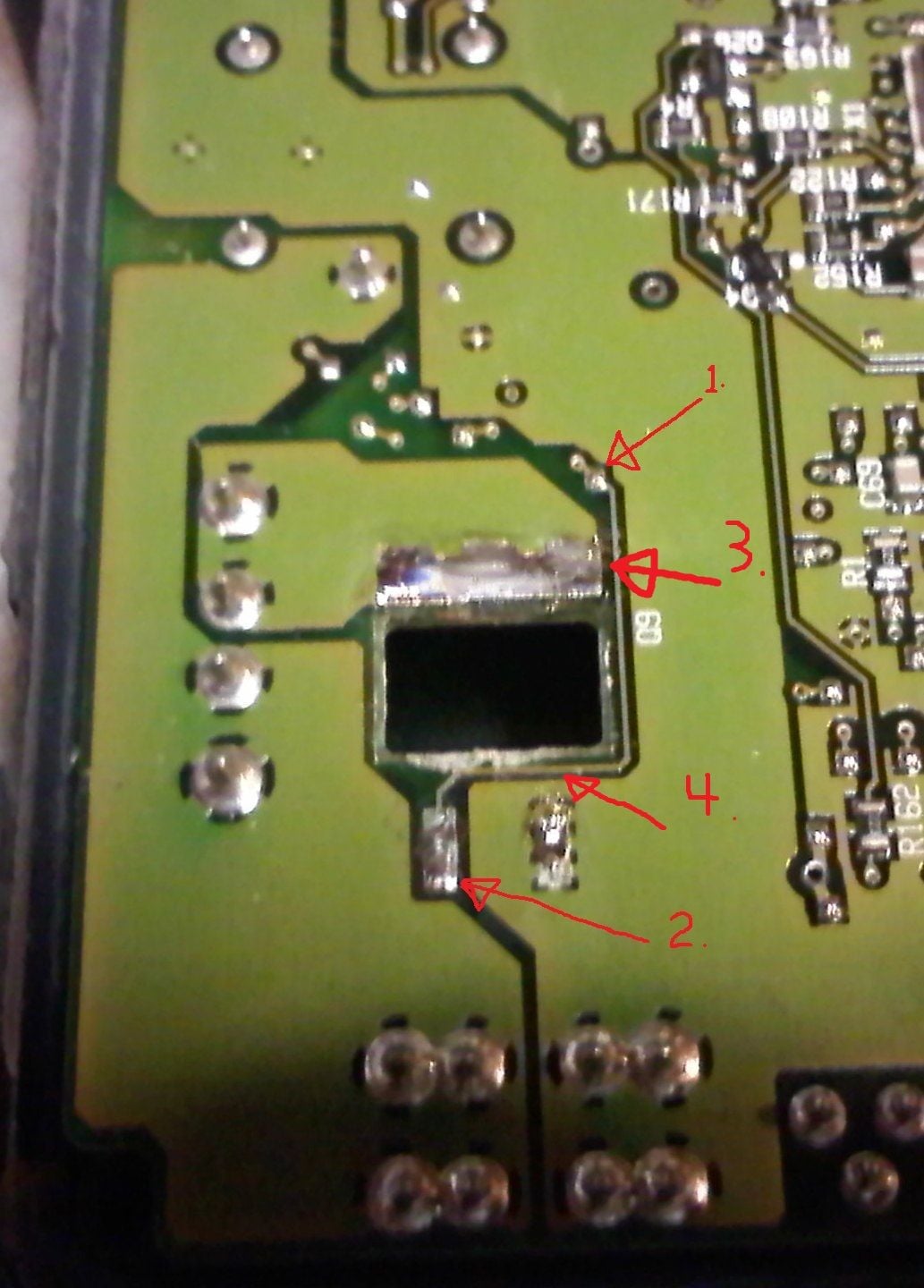

Another thing you might want to check again is for ether damage to the thin trace along the mosfet or a partial short to it. I'll throw up a photo of what I am talking about just in case.Hold on.

#104

I tested the traces and all was fine there. I also re-flowed all the solder joints on the relay last night and a few other joints that I wasn't pleased with. I haven't tested it since I re-flowed the joints. Figured I would see if you or anyone else had some other ideas before testing again.

#105

Here is a detail image of the thin trace. verify you have continuity from point 1 to 2 in photo and that its not shorted or partially shorted to the base of the mosfet at 3 or 4. I would also reflow the solder joints where the motor pins join the circuit board and where the 4 heavy pins of the front connector join it.

#107

I have been wielding a soldering iron for over 40 years and I still sometimes find on 2nd or 3rd inspection that I missed a little flash of solder or a bridge along the edge of something. Since my eyes have slowly gotten weaker, I have to inspect extra carefully, HEH, getting old can suck. Both of the modules you have should be virtually the same since they are both from 2000. The only likely difference is the program due to one having a standard cab vs a crew cab or long wheel vs short wheel base. There are also 2 different weight limit versions of the standard duty F-150, 6200 LB and 6700 lb. Kelsey-Hayes also ether used several suppliers of the mosfet in 2000 or did a production change during 2000 as the OP of this thread had one brand of mosfet in his 2000 controller and both of my controllers have a different mosfet. I also noticed slight differences in the circuit board layout from mine and a couple of the other photos in this thread. That's not uncommon during a several year run.

#108

I plan on testing my controller for a few days before I take it back off and silicone seal it shut. Its duct taped up for now. I will continue posting up the detailed photos and steps over the next day or so as well.

How much have you been cleaning out the case groove and rib joint before you re seal it? I scrapped out most of the old sealant and plan on going over it one last time before using new RTV high temp silicone. I also plan on using a scrap of high temp plastic from the junker Expedition to cover the hole in the bottom. During the summers here it can get very hot under the hood and standard plastics can start softening and warping in those temps.

How much have you been cleaning out the case groove and rib joint before you re seal it? I scrapped out most of the old sealant and plan on going over it one last time before using new RTV high temp silicone. I also plan on using a scrap of high temp plastic from the junker Expedition to cover the hole in the bottom. During the summers here it can get very hot under the hood and standard plastics can start softening and warping in those temps.

#109

Yeah...you have bout twice the solder time that I have under my belt. I have been soldering for about 22 years and I'm amazed at how many circuit boards I find with crappy solder joints. This is just frustrating because I have already shorted two brand new chips....(I tested them after removal as well and it was just the chip shorted...no issues I could find with the board traces or anything else). I'm apprehensive to test it out again on my truck. almost out of chips!

#110

one thing you might try as a last resort is to desolder each pin on the relay, one at a time and then resolder it with good rosin core solder, let cool then do another one. Always let them cool before going on to the next, trust me you don't want to know how I learned that part grrrr. I have seen a few times where arcing in a cracked solder joint contaminates the solder and the joint contacts enough to raise the resistance and cause issues. by removing all the old solder and flowing in fresh solder with good rosin flux it cleans the joint and gets rid of the arc contamination.