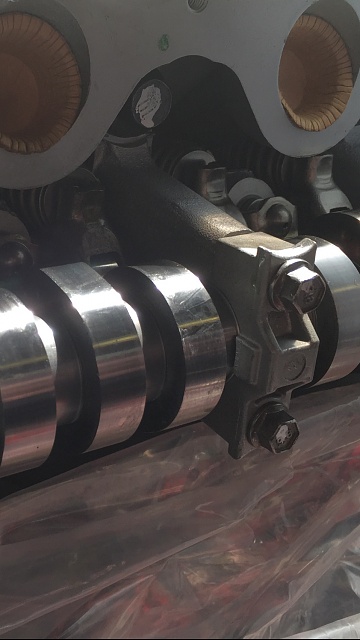

Should i be looking for a new head or is this repairable?

#11

Senior Member

iTrader: (1)

Originally Posted by Dirttracker18

I don't think you can align bore the heads as they do not use a bearing. If you do any boring it would become oversized with no way to take up the extra space, as an oversize bearing would.

It's the procedure that most of the reman manufacturers do on 3v heads to boost oil pressure in the hydraulic VCT system.

The OP's problem with the cam tower is not too uncommon. Although I doubt there's slag from a welder on the cam. I bet he could knock that bump down with a file, which would mean some wear causing particles were likely what caused his damage..

#12

Cycle For Fun and Health

My thought would be to take the bump off of the cam journal carefully and make sure it is smooth via some fine emery cloth. Also make sure the cam seat is smooth.

Put it back together and run.

I don't see this as being a major issue for oil pressure or longevity.

Put it back together and run.

I don't see this as being a major issue for oil pressure or longevity.

The following users liked this post:

Fx4Mark (03-06-2016)

#13

Senior Member

Fx4Mark,

Thanks for sharing the cam pics. What are you having the machine shop do? I'm not familiar enough with engine parts to know how much scoring is too much. My gut tells me you'll be okay by knocking the bump off the cam and smoothing out the journals as much as possible, but that's just my uneducated opinion. Let us know what the machine shop recommends.

Thanks for sharing the cam pics. What are you having the machine shop do? I'm not familiar enough with engine parts to know how much scoring is too much. My gut tells me you'll be okay by knocking the bump off the cam and smoothing out the journals as much as possible, but that's just my uneducated opinion. Let us know what the machine shop recommends.

#14

Senior Member

You can you just need to spec a custom cam bearing for the stock cam.

It's the procedure that most of the reman manufacturers do on 3v heads to boost oil pressure in the hydraulic VCT system.

The OP's problem with the cam tower is not too uncommon. Although I doubt there's slag from a welder on the cam. I bet he could knock that bump down with a file, which would mean some wear causing particles were likely what caused his damage..

It's the procedure that most of the reman manufacturers do on 3v heads to boost oil pressure in the hydraulic VCT system.

The OP's problem with the cam tower is not too uncommon. Although I doubt there's slag from a welder on the cam. I bet he could knock that bump down with a file, which would mean some wear causing particles were likely what caused his damage..

Correct me if I'm wrong but this configuration comes factory with no bearing, correct?

So there is a means in the aftermarket to put a bearing in?

To update this I looked around and answered my own question. There are aftermarket bearings available but you have to have a tang machined into the cap and it seems few shops do this.

#15

Junior Member

Thread Starter

Rick's 06,

I'm having them do valve jobs on both cylinders and plain the bottoms. For this head Im going to "attempt" to have them knock the bump, on the cam off and see if they can just clean up the seat. When it scratch it, the sides of the scratch moved up and made the clearence to tight and it doesn't turn very easy. This all started with a burnt valve on the other head. while i was in there i figured i would do both head gaskets, timing guides, chains tensioners (both had gaskets that were blown), VCT solenoids and phasers. and both manifolds. its just that now the engine bay is empty everything is easier to get at.

I'm having them do valve jobs on both cylinders and plain the bottoms. For this head Im going to "attempt" to have them knock the bump, on the cam off and see if they can just clean up the seat. When it scratch it, the sides of the scratch moved up and made the clearence to tight and it doesn't turn very easy. This all started with a burnt valve on the other head. while i was in there i figured i would do both head gaskets, timing guides, chains tensioners (both had gaskets that were blown), VCT solenoids and phasers. and both manifolds. its just that now the engine bay is empty everything is easier to get at.

#16

Senior Member

iTrader: (1)

Originally Posted by Dirttracker18

So you can get a bearing for this head?

Correct me if I'm wrong but this configuration comes factory with no bearing, correct?

So there is a means in the aftermarket to put a bearing in?

To update this I looked around and answered my own question. There are aftermarket bearings available but you have to have a tang machined into the cap and it seems few shops do this.

Correct me if I'm wrong but this configuration comes factory with no bearing, correct?

So there is a means in the aftermarket to put a bearing in?

To update this I looked around and answered my own question. There are aftermarket bearings available but you have to have a tang machined into the cap and it seems few shops do this.

My new heads got them.

I have no idea about machining the tang..

Old head did not.

#17

Junior Member

Thread Starter

UPDATE: Got the head to the machine shop said that it's nothing this isn't the first one like this they have seen. They have seen them that they were in pieces they are going to knock the burr off and flatten out the journal without changing the clearances i asked about the groove and they said it's just gonna get more oil, which can't be a bad thing.

#18

Cycle For Fun and Health

Good news.

How about posting progress as you get the work completed?

Hope everything goes back together good.

How about posting progress as you get the work completed?

Hope everything goes back together good.