High Milage 04 5.4 .. what would you do?

#21

LightningRod

Well Guys - I put in a quart of Kreen from Kano Labs last Tuesday (more about that later) and Thursday did the remove, clean, swap of VCTs and went back with full synthetic 5w30 Mobil 1. Started up and ran PERFECTLY, just as usual. Reset codes and off I go. Five drive cycles and couple hundred miles - got usual good oil pressure and getup-and-go, starts, pulls-passes good. Usual slight 2-3 sec chain noise on startup, "tick" at full EOT. So Friday, I go straight for that same ole long gradual uphill grade - at 60 mph, 4th gear OD. Tried to held her steady applying slight additional pedal. Crowned the hill about 43 mph in 3rd gear - WITH THE DAMN MIL LIT.  The two relative Torque reports follow:

The two relative Torque reports follow:

Fault log report generated by Torque for Android

=================================================

Vehicle VIN: 1FTPX12524NB61788

Vehicle Manufacturer: Ford

Vehicle Calibration ID: RXAQ1A5.HEX

Current Fault Log

------------------

P0022: "A" Camshaft Position - Timing Over-Retarded (Bank 2)

Pending Fault Log

------------------

ECU reports no pending faults

Historic Fault Log

------------------

ECU reports no historic faults

Other discovered fault codes

(possibly pending, current or manufacturer specific)

----------------------------------------------------

P1000: OBD-II Monitor Testing Incomplete

End of report.

--------------------------------------------------------------------------

Freeze frame report generated by Torque for Android

================================================== =======

Vehicle VIN: 1FTPX12524NB61788

Vehicle Manufacturer: Ford

Vehicle Calibration ID: RXAQ1A5.HEX

Freeze frame information:

------------------

Fuel Status = 0 byte

Engine Load = 89.804 %

Engine Coolant Temperature = 195.8 °F

Fuel Trim Bank 1 Short Term = 0.781 %

Fuel Trim Bank 1 Long Term = 17.188 %

Fuel Trim Bank 2 Short Term = 2.344 %

Fuel Trim Bank 2 Long Term = 0.781 %

Engine RPM = 2,488.25 rpm

Speed (OBD) = 45.981 mph

Timing Advance = 10.5 °

Intake Air Temperature = 91.4 °F

Mass Air Flow Rate = 726.738 cfm

Throttle Position(Manifold) = 76.471 %

Fuel trim bank 1 sensor 1 = 0.781 %

Fuel trim bank 2 sensor 1 = -0.781 %

Fuel Rail Pressure (relative to manifold vacuum) = 38.707 psi

Voltage (Control Module) = 13.966 V

Relative Throttle Position = 63.922 %

End of report.

------------------------------------------------------------------------

It may seem this thread has drifted too far off subject or been hi-jacked, but in a sense - not really. We are still talking about getting all the miles we can out of our great running 5.4s before having to do "SOMETHING?" about Phaser issues - quoting the OP by alsatropine:

It appears I am at the identical juncture. With 210,000 miles, she still runs great and has good pulling power. Has a little (2-3 sec) cold start chain rattle and the signature "tick" at hot idle, but the dieseling is mostly cured by running slightly heaver weight oils, but it's time to address the reoccurring P0022. I'm hoping I can do the job for considerably less than the $2900 suggested for a reman - even using OEM parts, a new water pump, idlers and ALL. With decent pressure running 5w30 (21-22 hot idle, 69-71 lbs cold idle) I think she's got plenty of life left. With a reman, I Would still have to buy some of those parts and pay shipping both ways. Although I think I will do a Melling racing pump for a little more volume looking for another 200K miles). And I will definitely take the skinned knuckles and aggravation over truck payments for the next five years or so!

I also think I will include new lash adjusters / followers hoping to address the "tick". I noticed something very informative (mentioned earlier) when preparing for my latest diagnostic effort ("VCT clean / swap") this week. It might help someone / somewhere / somehow. Short background: I have an aftermarket oil pressure gauge and have monitored pressures in conjunction with live scanner data from variable timing components, all while using different grades. I have been running 0w40 Mobil 1. Oil pressure stone cold runs around 70 with 0w40, which tells me the Zero weight is just fine - but the phasers seem to react sluggish on Torque Pro readings (which tells me 40 is too thick - that's why I went back to 5w30). NONE of this CURE my "tick" at hot idle, although it will purr like a kitten at cold idle with either.

I drained a quart out cold (what drains down your arm don't burn nearly as bad) before putting in the Kreen engine flush/cleaner. Don't know why but I had started it up and was idling when I poured the Kreen in - and I just DUMPED the whole damn quart of Kreen in all at once. I guess it hit the oil pan and, being thinner/lighter than oil, stayed generally on top of the oil and got picked up in the oil screen promptly, diluting the oil dramatically. HEAVEN TO BETSY! The lash adjusters on BOTH BANKS sounded like a "thrashing machine" instantly - (within 1 second of emptying the can of Kreen)- and the idle got ROUGH as hell. You would have thought I poured the stuff in the intake!. EVERY LAST lifter was "ticking" (clattering like hell), but begin to quiet down - and smooth out - right away. Within about 30 seconds, it had quieted completely down to its normal perfectly quiet -and smooth- cold idle. It just then hit me and I ran around and checked the Oil Pressure - and it was around 63 lbs, (wish I had known how low it dipped). The point being - I am convinced the ONLY thing I caused to happen was a dramatic, momentary dip in oil pressure, and as the Kreen mixed with the oil it came back up to normal. The "lifter" noise was directly proportional to the pressure - and the rough idle was directly related!

I am convinced the lash adjusters leak down to quickly at idle (even with 30 or 40 weight hot oil). A lash adjuster not pumping up fully (or leaking down) effects the lift height of its valve - which effects aspiration efficiency of the cylinder and this results in irregular combustion 'strength' across the cylinders (resulting in rough idle). I plan to replace all of them, and the followers with the timing components.

Sorry for the long windy post. But that's where I am. And I thank you guys for all your ideas and thoughts.

The two relative Torque reports follow:

The two relative Torque reports follow: Fault log report generated by Torque for Android

=================================================

Vehicle VIN: 1FTPX12524NB61788

Vehicle Manufacturer: Ford

Vehicle Calibration ID: RXAQ1A5.HEX

Current Fault Log

------------------

P0022: "A" Camshaft Position - Timing Over-Retarded (Bank 2)

Pending Fault Log

------------------

ECU reports no pending faults

Historic Fault Log

------------------

ECU reports no historic faults

Other discovered fault codes

(possibly pending, current or manufacturer specific)

----------------------------------------------------

P1000: OBD-II Monitor Testing Incomplete

End of report.

--------------------------------------------------------------------------

Freeze frame report generated by Torque for Android

================================================== =======

Vehicle VIN: 1FTPX12524NB61788

Vehicle Manufacturer: Ford

Vehicle Calibration ID: RXAQ1A5.HEX

Freeze frame information:

------------------

Fuel Status = 0 byte

Engine Load = 89.804 %

Engine Coolant Temperature = 195.8 °F

Fuel Trim Bank 1 Short Term = 0.781 %

Fuel Trim Bank 1 Long Term = 17.188 %

Fuel Trim Bank 2 Short Term = 2.344 %

Fuel Trim Bank 2 Long Term = 0.781 %

Engine RPM = 2,488.25 rpm

Speed (OBD) = 45.981 mph

Timing Advance = 10.5 °

Intake Air Temperature = 91.4 °F

Mass Air Flow Rate = 726.738 cfm

Throttle Position(Manifold) = 76.471 %

Fuel trim bank 1 sensor 1 = 0.781 %

Fuel trim bank 2 sensor 1 = -0.781 %

Fuel Rail Pressure (relative to manifold vacuum) = 38.707 psi

Voltage (Control Module) = 13.966 V

Relative Throttle Position = 63.922 %

End of report.

------------------------------------------------------------------------

It may seem this thread has drifted too far off subject or been hi-jacked, but in a sense - not really. We are still talking about getting all the miles we can out of our great running 5.4s before having to do "SOMETHING?" about Phaser issues - quoting the OP by alsatropine:

I have an 04 F150 Lariat 4x4 with the 5.4 3v. She has 221,000 miles on her which are mostly interstate miles. Engine runs like a champ, but does have the cam phaser sprocket issue. I will have the funds to purchase the phaser kit (Motorcraft) and I feel comfortable doing the repair myself. I replaced the chains about 20,000 miles ago but will replace them if I do the repair. My question is, would you go ahead and do the repair with the mileage on the engine? Need opinions folks. Thanks!

I also think I will include new lash adjusters / followers hoping to address the "tick". I noticed something very informative (mentioned earlier) when preparing for my latest diagnostic effort ("VCT clean / swap") this week. It might help someone / somewhere / somehow. Short background: I have an aftermarket oil pressure gauge and have monitored pressures in conjunction with live scanner data from variable timing components, all while using different grades. I have been running 0w40 Mobil 1. Oil pressure stone cold runs around 70 with 0w40, which tells me the Zero weight is just fine - but the phasers seem to react sluggish on Torque Pro readings (which tells me 40 is too thick - that's why I went back to 5w30). NONE of this CURE my "tick" at hot idle, although it will purr like a kitten at cold idle with either.

I drained a quart out cold (what drains down your arm don't burn nearly as bad) before putting in the Kreen engine flush/cleaner. Don't know why but I had started it up and was idling when I poured the Kreen in - and I just DUMPED the whole damn quart of Kreen in all at once. I guess it hit the oil pan and, being thinner/lighter than oil, stayed generally on top of the oil and got picked up in the oil screen promptly, diluting the oil dramatically. HEAVEN TO BETSY! The lash adjusters on BOTH BANKS sounded like a "thrashing machine" instantly - (within 1 second of emptying the can of Kreen)- and the idle got ROUGH as hell. You would have thought I poured the stuff in the intake!. EVERY LAST lifter was "ticking" (clattering like hell), but begin to quiet down - and smooth out - right away. Within about 30 seconds, it had quieted completely down to its normal perfectly quiet -and smooth- cold idle. It just then hit me and I ran around and checked the Oil Pressure - and it was around 63 lbs, (wish I had known how low it dipped). The point being - I am convinced the ONLY thing I caused to happen was a dramatic, momentary dip in oil pressure, and as the Kreen mixed with the oil it came back up to normal. The "lifter" noise was directly proportional to the pressure - and the rough idle was directly related!

I am convinced the lash adjusters leak down to quickly at idle (even with 30 or 40 weight hot oil). A lash adjuster not pumping up fully (or leaking down) effects the lift height of its valve - which effects aspiration efficiency of the cylinder and this results in irregular combustion 'strength' across the cylinders (resulting in rough idle). I plan to replace all of them, and the followers with the timing components.

Sorry for the long windy post. But that's where I am. And I thank you guys for all your ideas and thoughts.

#22

Senior Member

iTrader: (1)

Originally Posted by F150Torqued

Well Guys - I put in a quart of Kreen from Kano Labs last Tuesday (more about that later) and Thursday did the remove, clean, swap of VCTs and went back with full synthetic 5w30 Mobil 1. Started up and ran PERFECTLY, just as usual. Reset codes and off I go. Five drive cycles and couple hundred miles - got usual good oil pressure and getup-and-go, starts, pulls-passes good. Usual slight 2-3 sec chain noise on startup, "tick" at full EOT. So Friday, I go straight for that same ole long gradual uphill grade - at 60 mph, 4th gear OD. Tried to held her steady applying slight additional pedal. Crowned the hill about 43 mph in 3rd gear - WITH THE DAMN MIL LIT.  The two relative Torque reports follow:

The two relative Torque reports follow:

Fault log report generated by Torque for Android

=================================================

Vehicle VIN: 1FTPX12524NB61788

Vehicle Manufacturer: Ford

Vehicle Calibration ID: RXAQ1A5.HEX

Current Fault Log

------------------

P0022: "A" Camshaft Position - Timing Over-Retarded (Bank 2)

Pending Fault Log

------------------

ECU reports no pending faults

Historic Fault Log

------------------

ECU reports no historic faults

Other discovered fault codes

(possibly pending, current or manufacturer specific)

----------------------------------------------------

P1000: OBD-II Monitor Testing Incomplete

End of report.

--------------------------------------------------------------------------

Freeze frame report generated by Torque for Android

================================================== =======

Vehicle VIN: 1FTPX12524NB61788

Vehicle Manufacturer: Ford

Vehicle Calibration ID: RXAQ1A5.HEX

Freeze frame information:

------------------

Fuel Status = 0 byte

Engine Load = 89.804 %

Engine Coolant Temperature = 195.8 °F

Fuel Trim Bank 1 Short Term = 0.781 %

Fuel Trim Bank 1 Long Term = 17.188 %

Fuel Trim Bank 2 Short Term = 2.344 %

Fuel Trim Bank 2 Long Term = 0.781 %

Engine RPM = 2,488.25 rpm

Speed (OBD) = 45.981 mph

Timing Advance = 10.5 °

Intake Air Temperature = 91.4 °F

Mass Air Flow Rate = 726.738 cfm

Throttle Position(Manifold) = 76.471 %

Fuel trim bank 1 sensor 1 = 0.781 %

Fuel trim bank 2 sensor 1 = -0.781 %

Fuel Rail Pressure (relative to manifold vacuum) = 38.707 psi

Voltage (Control Module) = 13.966 V

Relative Throttle Position = 63.922 %

End of report.

------------------------------------------------------------------------

It may seem this thread has drifted too far off subject or been hi-jacked, but in a sense - not really. We are still talking about getting all the miles we can out of our great running 5.4s before having to do "SOMETHING?" about Phaser issues - quoting the OP by alsatropine:It appears I am at the identical juncture. With 210,000 miles, she still runs great and has good pulling power. Has a little (2-3 sec) cold start chain rattle and the signature "tick" at hot idle, but the dieseling is mostly cured by running slightly heaver weight oils, but it's time to address the reoccurring P0022. I'm hoping I can do the job for considerably less than the $2900 suggested for a reman - even using OEM parts, a new water pump, idlers and ALL. With decent pressure running 5w30 (21-22 hot idle, 69-71 lbs cold idle) I think she's got plenty of life left. With a reman, I Would still have to buy some of those parts and pay shipping both ways. Although I think I will do a Melling racing pump for a little more volume looking for another 200K miles). And I will definitely take the skinned knuckles and aggravation over truck payments for the next five years or so!

I also think I will include new lash adjusters / followers hoping to address the "tick". I noticed something very informative (mentioned earlier) when preparing for my latest diagnostic effort ("VCT clean / swap") this week. It might help someone / somewhere / somehow. Short background: I have an aftermarket oil pressure gauge and have monitored pressures in conjunction with live scanner data from variable timing components, all while using different grades. I have been running 0w40 Mobil 1. Oil pressure stone cold runs around 70 with 0w40, which tells me the Zero weight is just fine - but the phasers seem to react sluggish on Torque Pro readings (which tells me 40 is too thick - that's why I went back to 5w30). NONE of this CURE my "tick" at hot idle, although it will purr like a kitten at cold idle with either.

I drained a quart out cold (what drains down your arm don't burn nearly as bad) before putting in the Kreen engine flush/cleaner. Don't know why but I had started it up and was idling when I poured the Kreen in - and I just DUMPED the whole damn quart of Kreen in all at once. I guess it hit the oil pan and, being thinner/lighter than oil, stayed generally on top of the oil and got picked up in the oil screen promptly, diluting the oil dramatically. HEAVEN TO BETSY! The lash adjusters on BOTH BANKS sounded like a "thrashing machine" instantly - (within 1 second of emptying the can of Kreen)- and the idle got ROUGH as hell. You would have thought I poured the stuff in the intake!. EVERY LAST lifter was "ticking" (clattering like hell), but begin to quiet down - and smooth out - right away. Within about 30 seconds, it had quieted completely down to its normal perfectly quiet -and smooth- cold idle. It just then hit me and I ran around and checked the Oil Pressure - and it was around 63 lbs, (wish I had known how low it dipped). The point being - I am convinced the ONLY thing I caused to happen was a dramatic, momentary dip in oil pressure, and as the Kreen mixed with the oil it came back up to normal. The "lifter" noise was directly proportional to the pressure - and the rough idle was directly related!

I am convinced the lash adjusters leak down to quickly at idle (even with 30 or 40 weight hot oil). A lash adjuster not pumping up fully (or leaking down) effects the lift height of its valve - which effects aspiration efficiency of the cylinder and this results in irregular combustion 'strength' across the cylinders (resulting in rough idle). I plan to replace all of them, and the followers with the timing components.

Sorry for the long windy post. But that's where I am. And I thank you guys for all your ideas and thoughts.

The two relative Torque reports follow:

The two relative Torque reports follow: Fault log report generated by Torque for Android

=================================================

Vehicle VIN: 1FTPX12524NB61788

Vehicle Manufacturer: Ford

Vehicle Calibration ID: RXAQ1A5.HEX

Current Fault Log

------------------

P0022: "A" Camshaft Position - Timing Over-Retarded (Bank 2)

Pending Fault Log

------------------

ECU reports no pending faults

Historic Fault Log

------------------

ECU reports no historic faults

Other discovered fault codes

(possibly pending, current or manufacturer specific)

----------------------------------------------------

P1000: OBD-II Monitor Testing Incomplete

End of report.

--------------------------------------------------------------------------

Freeze frame report generated by Torque for Android

================================================== =======

Vehicle VIN: 1FTPX12524NB61788

Vehicle Manufacturer: Ford

Vehicle Calibration ID: RXAQ1A5.HEX

Freeze frame information:

------------------

Fuel Status = 0 byte

Engine Load = 89.804 %

Engine Coolant Temperature = 195.8 °F

Fuel Trim Bank 1 Short Term = 0.781 %

Fuel Trim Bank 1 Long Term = 17.188 %

Fuel Trim Bank 2 Short Term = 2.344 %

Fuel Trim Bank 2 Long Term = 0.781 %

Engine RPM = 2,488.25 rpm

Speed (OBD) = 45.981 mph

Timing Advance = 10.5 °

Intake Air Temperature = 91.4 °F

Mass Air Flow Rate = 726.738 cfm

Throttle Position(Manifold) = 76.471 %

Fuel trim bank 1 sensor 1 = 0.781 %

Fuel trim bank 2 sensor 1 = -0.781 %

Fuel Rail Pressure (relative to manifold vacuum) = 38.707 psi

Voltage (Control Module) = 13.966 V

Relative Throttle Position = 63.922 %

End of report.

------------------------------------------------------------------------

It may seem this thread has drifted too far off subject or been hi-jacked, but in a sense - not really. We are still talking about getting all the miles we can out of our great running 5.4s before having to do "SOMETHING?" about Phaser issues - quoting the OP by alsatropine:It appears I am at the identical juncture. With 210,000 miles, she still runs great and has good pulling power. Has a little (2-3 sec) cold start chain rattle and the signature "tick" at hot idle, but the dieseling is mostly cured by running slightly heaver weight oils, but it's time to address the reoccurring P0022. I'm hoping I can do the job for considerably less than the $2900 suggested for a reman - even using OEM parts, a new water pump, idlers and ALL. With decent pressure running 5w30 (21-22 hot idle, 69-71 lbs cold idle) I think she's got plenty of life left. With a reman, I Would still have to buy some of those parts and pay shipping both ways. Although I think I will do a Melling racing pump for a little more volume looking for another 200K miles). And I will definitely take the skinned knuckles and aggravation over truck payments for the next five years or so!

I also think I will include new lash adjusters / followers hoping to address the "tick". I noticed something very informative (mentioned earlier) when preparing for my latest diagnostic effort ("VCT clean / swap") this week. It might help someone / somewhere / somehow. Short background: I have an aftermarket oil pressure gauge and have monitored pressures in conjunction with live scanner data from variable timing components, all while using different grades. I have been running 0w40 Mobil 1. Oil pressure stone cold runs around 70 with 0w40, which tells me the Zero weight is just fine - but the phasers seem to react sluggish on Torque Pro readings (which tells me 40 is too thick - that's why I went back to 5w30). NONE of this CURE my "tick" at hot idle, although it will purr like a kitten at cold idle with either.

I drained a quart out cold (what drains down your arm don't burn nearly as bad) before putting in the Kreen engine flush/cleaner. Don't know why but I had started it up and was idling when I poured the Kreen in - and I just DUMPED the whole damn quart of Kreen in all at once. I guess it hit the oil pan and, being thinner/lighter than oil, stayed generally on top of the oil and got picked up in the oil screen promptly, diluting the oil dramatically. HEAVEN TO BETSY! The lash adjusters on BOTH BANKS sounded like a "thrashing machine" instantly - (within 1 second of emptying the can of Kreen)- and the idle got ROUGH as hell. You would have thought I poured the stuff in the intake!. EVERY LAST lifter was "ticking" (clattering like hell), but begin to quiet down - and smooth out - right away. Within about 30 seconds, it had quieted completely down to its normal perfectly quiet -and smooth- cold idle. It just then hit me and I ran around and checked the Oil Pressure - and it was around 63 lbs, (wish I had known how low it dipped). The point being - I am convinced the ONLY thing I caused to happen was a dramatic, momentary dip in oil pressure, and as the Kreen mixed with the oil it came back up to normal. The "lifter" noise was directly proportional to the pressure - and the rough idle was directly related!

I am convinced the lash adjusters leak down to quickly at idle (even with 30 or 40 weight hot oil). A lash adjuster not pumping up fully (or leaking down) effects the lift height of its valve - which effects aspiration efficiency of the cylinder and this results in irregular combustion 'strength' across the cylinders (resulting in rough idle). I plan to replace all of them, and the followers with the timing components.

Sorry for the long windy post. But that's where I am. And I thank you guys for all your ideas and thoughts.

LT fuel trims on bank 1 are awful, and not much better on bank 2.

This huge disparity does say that bank 1 is definitely the side to watch.. (Passenger side)

Makes me wonder about an injector on bank 1, or possibly an intake manifold issue gasket issue... Any cylinders on bank 1 throwing a miss code ever?

Your IAT's are 91 degrees, what was the temp that day of the freeze frame?

Now you said that dumping the kreen in caused a momentary aweful racket. Did you notice any racket or rough running beginning to happen as soon as the oil fill cap was removed, just prior to pouring kreen?

I'd be inclined to side with your idea that lash adjusters are causing valve lift issues.. Since VCT is only on the intake valves, than I would be wondering what the 02's are reporting via tourqe app.. Plus, how old are your front 02 sensors?

Stuck lash adjusters should not cause too much chaos considering the valve spring is doing all the "lifting".. The vct just alters the valves opening effect of overcoming the spring pressure. The valves ability to return is only subject to cam lobe placement on the cam follower. The lash adjuster is basically like spounge to absorb, cushion, and keep the cam follower resting securely with the valve stem. When seized in the up position, I'd say a lash adjusters affect on valve lift would be showing lean issues which you are certainly showing with BANK 1 LT FUEL TRIM.. I'd still diagnose further, because the trims are definitely saying something is not right with the air entering the bank 1 cylinders, and then fuels accordingly..

A lash adjuster is absolutely a wear item, and will not live forever or even nearly as long as a cam journal, or piston ring.. 200k is a good life span for lash adjusters.. They are essential to replace when rebuilding the timing set..

So other than this 1 replicable issue on a hill, the engine runs good and idles smooth? Has good stumble free power off the line, and revs up clean right to 4K+ rpms..

#23

LightningRod

Thanks 1,000,000 @Especial86 for the comments and discussion.

LT fuel trims on bank 1 are awful, and not much better on bank 2.

This huge disparity does say that bank 1 is definitely the side to watch.. (Passenger side)

Makes me wonder about an injector on bank 1, or possibly an intake manifold issue gasket issue... Any cylinders on bank 1 throwing a miss code ever?

I concur. Don't you think "over-retard" condition in Bank 2 speaks for this disparity (at least in part)? The IM was replaced some time ago and cured lean problems on both banks. NO MISFIRES AT ALL.

Your IAT's are 91 degrees, what was the temp that day of the freeze frame?

Hey man, I'm in South Texas! LOL. Actually, outside temp that day was probably in mid 80s. And I routinely see IAT that much above ambient temp when the vehicle is moving. Stop & Go traffic will make it 120 when ECT is 195. I've verified it's correctness against dashboard temp at morning startup.

Now you said that dumping the kreen in caused a momentary awful racket. Did you notice any racket or rough running beginning to happen as soon as the oil fill cap was removed, just prior to pouring kreen?

No. I've stuffed a stethoscope down the oil filler hole and listened to that freight train before. It wasn't that. The 'thrashing machine' noise blossomed within 2 seconds of my DUMPING the engine flush in the funnel. (And I think the result was a revelation.)

I'd be inclined to side with your idea that lash adjusters are causing valve lift issues.. Since VCT is only on the intake valves, than I would be wondering what the 02's are reporting via Torque App.. Plus, how old are your front 02 sensors?

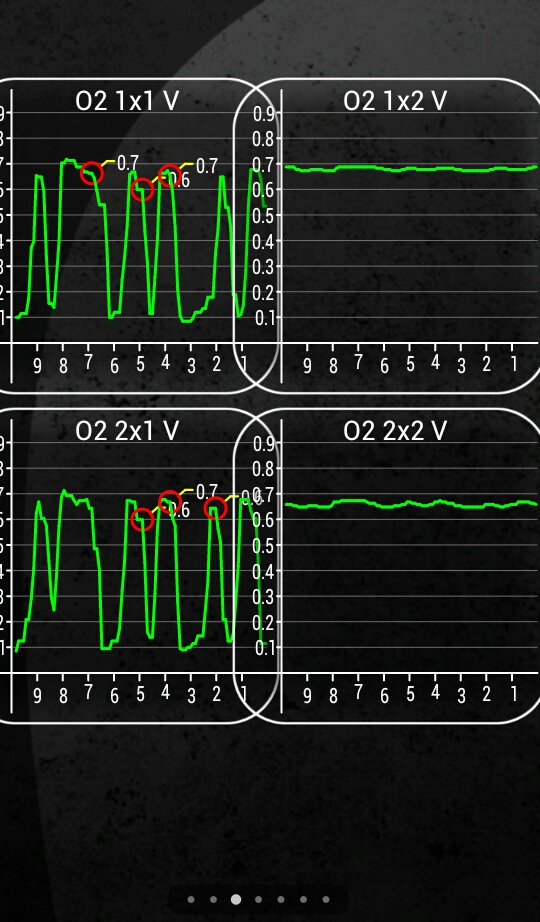

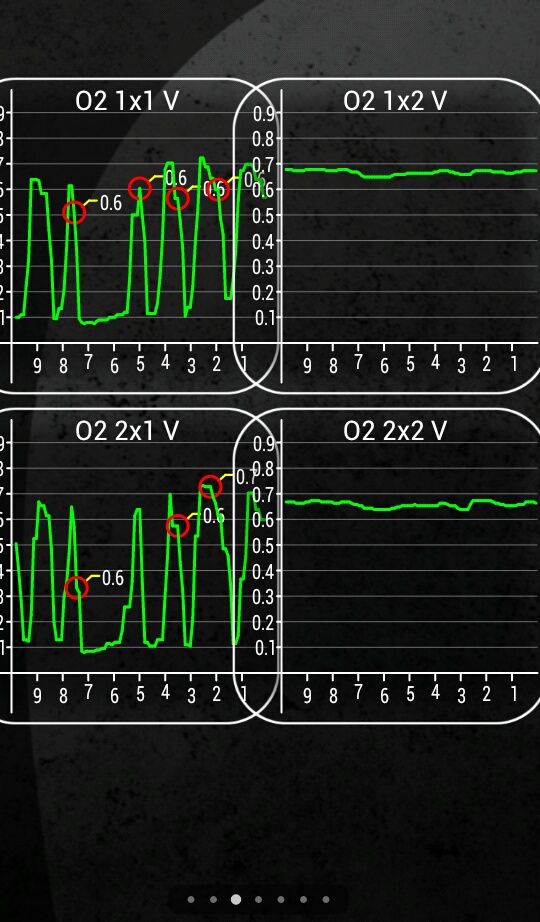

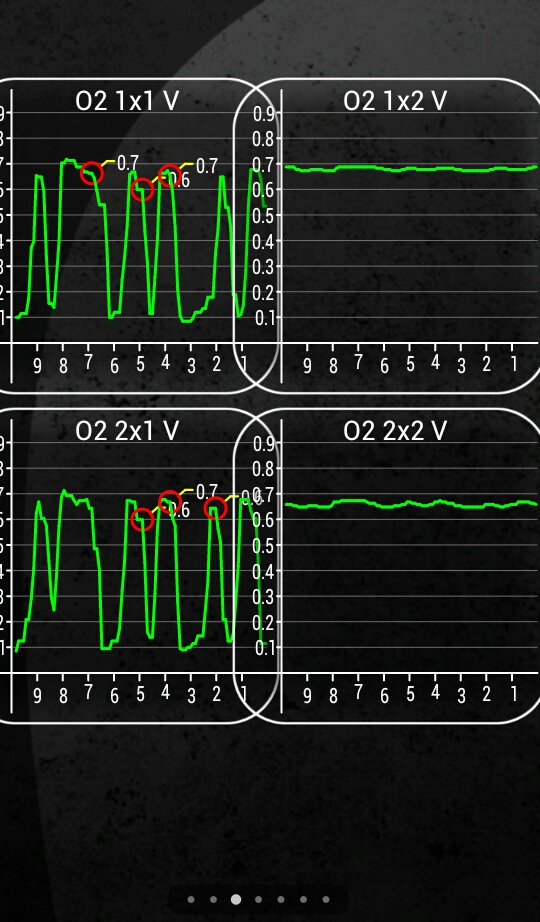

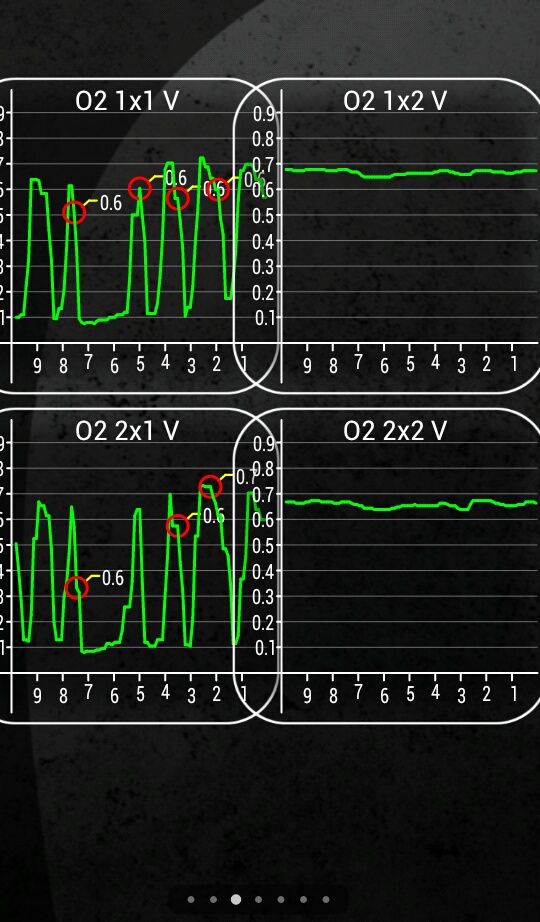

All four O2's have about 80k miles on them and seem to be functioning quiet well:

Screenshot of O2 sensor graphs @ idle

Screenshot of O2 sensor graphs @ gentle cruise

All continuous Emissions tests pass and Mode $06 emissions tests are within range (No P0340 code). This leads me to believe the disparity in LFT's is a result of Bank 1 just may be having to do more of the actual work pulling bank 2 along. [I respectfully disagree with "... Since VCT is only on the intake valves..."] VCT - on a SHOC retards both intake and exhaust together, and the over-retard condition would effect aspiration as well as regurgitating exhaust gases, cooling combustion and leading to a 'less robust' combustion. (You have my permission to discount all that as shade tree bull **** logic.)

Stuck lash adjusters should not cause too much chaos considering the valve spring is doing all the "lifting".. The vct just alters the valves opening effect of overcoming the spring pressure. The valves ability to return is only subject to cam lobe placement on the cam follower. The lash adjuster is basically like spounge to absorb, cushion, and keep the cam follower resting securely with the valve stem. When seized in the up position, I'd say a lash adjusters affect on valve lift would be showing lean issues which you are certainly showing with BANK 1 LT FUEL TRIM.. I'd still diagnose further, because the trims are definitely saying something is not right with the air entering the bank 1 cylinders, and then fuels accordingly..

I said it wrong, since the valve sits upside down. By 'lift' I was referring to its opening being dampened by leaky lash adjusters or their collapsing under pressure of the lobe / spring, and not pumping up quick enough. The reason I think this may be so significant is the "cantilever" effect of the design. It's a shorter distance from the lash adjuster to the follower roller than it is from the roller to the valve stem. Thus, any 'give' in the lash adjuster is amplified in the amount the valve is opened - by the cantilever ratio. (You have my permission to discount that one too! lol)

A lash adjuster is absolutely a wear item, and will not live forever or even nearly as long as a cam journal, or piston ring.. 200k is a good life span for lash adjusters.. They are essential to replace when rebuilding the timing set.

Agreed. I think they may be the culprit in rough idle complaints.

So other than this 1 replicable issue on a hill, the engine runs good and idles smooth? Has good stumble free power off the line, and revs up clean right to 4K+ rpms..

Yes. Other than the P0022, the engine is killer strong. Dieseling is non-existent with 0w40. Idles smooth except a slight roughness develops at 595-615 RPM idle at full EOT (coinciding with the emergence of the "tick"). And it will rev like a 283cu Chevy ----- well maybe not like that, --- but I've rapped it up to even 5K. And with my 4000 lb boat behind it, if you don't get rolling at least 3-4 miles per hour before floor boarding it - it'll burn rubber. BTW, that would be the same boat that mangled my tail gate when I didn't have it hitched correctly this fall. Now the tail gate AND the driver's seat cushion are the only things wrong with it!

LT fuel trims on bank 1 are awful, and not much better on bank 2.

This huge disparity does say that bank 1 is definitely the side to watch.. (Passenger side)

Makes me wonder about an injector on bank 1, or possibly an intake manifold issue gasket issue... Any cylinders on bank 1 throwing a miss code ever?

I concur. Don't you think "over-retard" condition in Bank 2 speaks for this disparity (at least in part)? The IM was replaced some time ago and cured lean problems on both banks. NO MISFIRES AT ALL.

Your IAT's are 91 degrees, what was the temp that day of the freeze frame?

Hey man, I'm in South Texas! LOL. Actually, outside temp that day was probably in mid 80s. And I routinely see IAT that much above ambient temp when the vehicle is moving. Stop & Go traffic will make it 120 when ECT is 195. I've verified it's correctness against dashboard temp at morning startup.

Now you said that dumping the kreen in caused a momentary awful racket. Did you notice any racket or rough running beginning to happen as soon as the oil fill cap was removed, just prior to pouring kreen?

No. I've stuffed a stethoscope down the oil filler hole and listened to that freight train before. It wasn't that. The 'thrashing machine' noise blossomed within 2 seconds of my DUMPING the engine flush in the funnel. (And I think the result was a revelation.)

I'd be inclined to side with your idea that lash adjusters are causing valve lift issues.. Since VCT is only on the intake valves, than I would be wondering what the 02's are reporting via Torque App.. Plus, how old are your front 02 sensors?

All four O2's have about 80k miles on them and seem to be functioning quiet well:

Screenshot of O2 sensor graphs @ idle

Screenshot of O2 sensor graphs @ gentle cruise

All continuous Emissions tests pass and Mode $06 emissions tests are within range (No P0340 code). This leads me to believe the disparity in LFT's is a result of Bank 1 just may be having to do more of the actual work pulling bank 2 along. [I respectfully disagree with "... Since VCT is only on the intake valves..."] VCT - on a SHOC retards both intake and exhaust together, and the over-retard condition would effect aspiration as well as regurgitating exhaust gases, cooling combustion and leading to a 'less robust' combustion. (You have my permission to discount all that as shade tree bull **** logic.)

Stuck lash adjusters should not cause too much chaos considering the valve spring is doing all the "lifting".. The vct just alters the valves opening effect of overcoming the spring pressure. The valves ability to return is only subject to cam lobe placement on the cam follower. The lash adjuster is basically like spounge to absorb, cushion, and keep the cam follower resting securely with the valve stem. When seized in the up position, I'd say a lash adjusters affect on valve lift would be showing lean issues which you are certainly showing with BANK 1 LT FUEL TRIM.. I'd still diagnose further, because the trims are definitely saying something is not right with the air entering the bank 1 cylinders, and then fuels accordingly..

I said it wrong, since the valve sits upside down. By 'lift' I was referring to its opening being dampened by leaky lash adjusters or their collapsing under pressure of the lobe / spring, and not pumping up quick enough. The reason I think this may be so significant is the "cantilever" effect of the design. It's a shorter distance from the lash adjuster to the follower roller than it is from the roller to the valve stem. Thus, any 'give' in the lash adjuster is amplified in the amount the valve is opened - by the cantilever ratio. (You have my permission to discount that one too! lol)

A lash adjuster is absolutely a wear item, and will not live forever or even nearly as long as a cam journal, or piston ring.. 200k is a good life span for lash adjusters.. They are essential to replace when rebuilding the timing set.

Agreed. I think they may be the culprit in rough idle complaints.

So other than this 1 replicable issue on a hill, the engine runs good and idles smooth? Has good stumble free power off the line, and revs up clean right to 4K+ rpms..

Yes. Other than the P0022, the engine is killer strong. Dieseling is non-existent with 0w40. Idles smooth except a slight roughness develops at 595-615 RPM idle at full EOT (coinciding with the emergence of the "tick"). And it will rev like a 283cu Chevy ----- well maybe not like that, --- but I've rapped it up to even 5K. And with my 4000 lb boat behind it, if you don't get rolling at least 3-4 miles per hour before floor boarding it - it'll burn rubber. BTW, that would be the same boat that mangled my tail gate when I didn't have it hitched correctly this fall. Now the tail gate AND the driver's seat cushion are the only things wrong with it!

Last edited by F150Torqued; 11-24-2015 at 01:01 AM. Reason: spelling & corrected IMG display

#24

Senior Member

iTrader: (1)

Originally Posted by F150Torqued

Thanks 1,000,000 @Especial86 for the comments and discussion.

LT fuel trims on bank 1 are awful, and not much better on bank 2.

This huge disparity does say that bank 1 is definitely the side to watch.. (Passenger side)

Makes me wonder about an injector on bank 1, or possibly an intake manifold issue gasket issue... Any cylinders on bank 1 throwing a miss code ever?

I concur. Don't you think "over-retard" condition in Bank 2 speaks for this disparity (at least in part)? The IM was replaced some time ago and cured lean problems on both banks. NO MISFIRES AT ALL.

Your IAT's are 91 degrees, what was the temp that day of the freeze frame?

Hey man, I'm in South Texas! LOL. Actually, outside temp that day was probably in mid 80s. And I routinely see IAT that much above ambient temp when the vehicle is moving. Stop & Go traffic will make it 120 when ECT is 195. I've verified it's correctness against dashboard temp at morning startup.

Now you said that dumping the kreen in caused a momentary aweful racket. Did you notice any racket or rough running beginning to happen as soon as the oil fill cap was removed, just prior to pouring kreen?

No. I've stuffed a stethoscope down the oil filler hole and listened to that freight train before. It wasn't that. The 'thrashing machine' noise blossomed within 2 seconds of my DUMPING the engine flush in the funnel. (And I think the result was a revelation.)

I'd be inclined to side with your idea that lash adjusters are causing valve lift issues.. Since VCT is only on the intake valves, than I would be wondering what the 02's are reporting via tourqe app.. Plus, how old are your front 02 sensors?

All four O2's have about 80k miles on them and seem to be functioning quiet well: http://www.devoll.com/remote_images/Screenshot%2015-02-02%20O2s%20gentle%20cruise.jpg All continuous Emissions tests pass and Mode $06 emissions tests are within range (No P0340 code). This leads me to believe the disparity in LFT's is a result of Bank 1 just may be having to do more of the actual work pulling bank 2 along. [I respectfully disagree with "... Since VCT is only on the intake valves..."] VCT - on a SHOC retards both intake and exhaust together, and the over-retard condition would effect aspiration as well as regurgitating exhaust gases, cooling combustion and leading to a 'less robust' combustion. (You have my permission to discount all that as shade tree bull **** logic.)

Stuck lash adjusters should not cause too much chaos considering the valve spring is doing all the "lifting".. The vct just alters the valves opening effect of overcoming the spring pressure. The valves ability to return is only subject to cam lobe placement on the cam follower. The lash adjuster is basically like spounge to absorb, cushion, and keep the cam follower resting securely with the valve stem. When seized in the up position, I'd say a lash adjusters affect on valve lift would be showing lean issues which you are certainly showing with BANK 1 LT FUEL TRIM.. I'd still diagnose further, because the trims are definitely saying something is not right with the air entering the bank 1 cylinders, and then fuels accordingly..

I said it wrong, since the valve sits upside down. By 'lift' I was referring to its opening being dampened by leaky lash adjusters or their collapsing under pressure of the lobe / spring, and not pumping up quick enough. The reason I think this may be so significant is the "cantilever" effect of the design. It's a shorter distance from the lash adjuster to the follower roller than it is from the roller to the valve stem. Thus, any 'give' in the lash adjuster is amplified in the amount the valve is opened - by the cantilever ratio. (You have my permission to discount that one too! lol)

A lash adjuster is absolutely a wear item, and will not live forever or even nearly as long as a cam journal, or piston ring.. 200k is a good life span for lash adjusters.. They are essential to replace when rebuilding the timing set.

Agreed. I think they may be the culprit in rough idle complaints.

So other than this 1 replicable issue on a hill, the engine runs good and idles smooth? Has good stumble free power off the line, and revs up clean right to 4K+ rpms..

Yes. Other than the P0022, the engine is killer strong. Dieseling is non-existent with 0w40. Idles smooth except a slight roughness develops at 595-615 RPM idle at full EOT (coinciding with the emergence of the "tick"). And it will rev like a 283cu Chevy ----- well maybe not like that, --- but I've rapped it up to even 5K. And with my 4000 lb boat behind it, if you don't get rolling at least 3-4 miles per hour before floor boarding it - it'll burn rubber. BTW, that would be the same boat that mangled my tail gate when I didn't have it hitched correctly this fall. Now the tail gate AND the driver's seat cushion are the only things wrong with it!

LT fuel trims on bank 1 are awful, and not much better on bank 2.

This huge disparity does say that bank 1 is definitely the side to watch.. (Passenger side)

Makes me wonder about an injector on bank 1, or possibly an intake manifold issue gasket issue... Any cylinders on bank 1 throwing a miss code ever?

I concur. Don't you think "over-retard" condition in Bank 2 speaks for this disparity (at least in part)? The IM was replaced some time ago and cured lean problems on both banks. NO MISFIRES AT ALL.

Your IAT's are 91 degrees, what was the temp that day of the freeze frame?

Hey man, I'm in South Texas! LOL. Actually, outside temp that day was probably in mid 80s. And I routinely see IAT that much above ambient temp when the vehicle is moving. Stop & Go traffic will make it 120 when ECT is 195. I've verified it's correctness against dashboard temp at morning startup.

Now you said that dumping the kreen in caused a momentary aweful racket. Did you notice any racket or rough running beginning to happen as soon as the oil fill cap was removed, just prior to pouring kreen?

No. I've stuffed a stethoscope down the oil filler hole and listened to that freight train before. It wasn't that. The 'thrashing machine' noise blossomed within 2 seconds of my DUMPING the engine flush in the funnel. (And I think the result was a revelation.)

I'd be inclined to side with your idea that lash adjusters are causing valve lift issues.. Since VCT is only on the intake valves, than I would be wondering what the 02's are reporting via tourqe app.. Plus, how old are your front 02 sensors?

All four O2's have about 80k miles on them and seem to be functioning quiet well: http://www.devoll.com/remote_images/Screenshot%2015-02-02%20O2s%20gentle%20cruise.jpg All continuous Emissions tests pass and Mode $06 emissions tests are within range (No P0340 code). This leads me to believe the disparity in LFT's is a result of Bank 1 just may be having to do more of the actual work pulling bank 2 along. [I respectfully disagree with "... Since VCT is only on the intake valves..."] VCT - on a SHOC retards both intake and exhaust together, and the over-retard condition would effect aspiration as well as regurgitating exhaust gases, cooling combustion and leading to a 'less robust' combustion. (You have my permission to discount all that as shade tree bull **** logic.)

Stuck lash adjusters should not cause too much chaos considering the valve spring is doing all the "lifting".. The vct just alters the valves opening effect of overcoming the spring pressure. The valves ability to return is only subject to cam lobe placement on the cam follower. The lash adjuster is basically like spounge to absorb, cushion, and keep the cam follower resting securely with the valve stem. When seized in the up position, I'd say a lash adjusters affect on valve lift would be showing lean issues which you are certainly showing with BANK 1 LT FUEL TRIM.. I'd still diagnose further, because the trims are definitely saying something is not right with the air entering the bank 1 cylinders, and then fuels accordingly..

I said it wrong, since the valve sits upside down. By 'lift' I was referring to its opening being dampened by leaky lash adjusters or their collapsing under pressure of the lobe / spring, and not pumping up quick enough. The reason I think this may be so significant is the "cantilever" effect of the design. It's a shorter distance from the lash adjuster to the follower roller than it is from the roller to the valve stem. Thus, any 'give' in the lash adjuster is amplified in the amount the valve is opened - by the cantilever ratio. (You have my permission to discount that one too! lol)

A lash adjuster is absolutely a wear item, and will not live forever or even nearly as long as a cam journal, or piston ring.. 200k is a good life span for lash adjusters.. They are essential to replace when rebuilding the timing set.

Agreed. I think they may be the culprit in rough idle complaints.

So other than this 1 replicable issue on a hill, the engine runs good and idles smooth? Has good stumble free power off the line, and revs up clean right to 4K+ rpms..

Yes. Other than the P0022, the engine is killer strong. Dieseling is non-existent with 0w40. Idles smooth except a slight roughness develops at 595-615 RPM idle at full EOT (coinciding with the emergence of the "tick"). And it will rev like a 283cu Chevy ----- well maybe not like that, --- but I've rapped it up to even 5K. And with my 4000 lb boat behind it, if you don't get rolling at least 3-4 miles per hour before floor boarding it - it'll burn rubber. BTW, that would be the same boat that mangled my tail gate when I didn't have it hitched correctly this fall. Now the tail gate AND the driver's seat cushion are the only things wrong with it!

I might agree that you got a sticking lash adjuster issue, but that over retard code on bank 2 is just odd considering the developments on bank 1.. It's almost like the PCM loses control of 1 of the banks.

Can you watch desired vct angle with tourqe app? I'm curious to see what your vct angles are under 80% load.. Sounds like your PCM is trying to pull timing which means the PCM is hearing knock, and trying to retard.. On my truck before the supercharger, with a php tune, vct would zero out under heavy load, with only spark advance being raised.

So I wonder if you have a butterfly valve on bank 1 stuck open while bank 2 still works on the cmcv valve.. I also wonder if there is an intake manifold leak on bank 1 as well.. If you pulled the oil cap off, and noticed zero idle change while the engine was running, it sounds like there could be a leak somewhere in the vac or pcv system.. You should hear idle adjust to overcome the crankcase pressure being broken.. If there's no pressure than there's a leak. If there's a huge amount of vaccum, enough to suck the fill cap to the full neck and even smother the motor than that is a valve stuck open..

#25

LightningRod

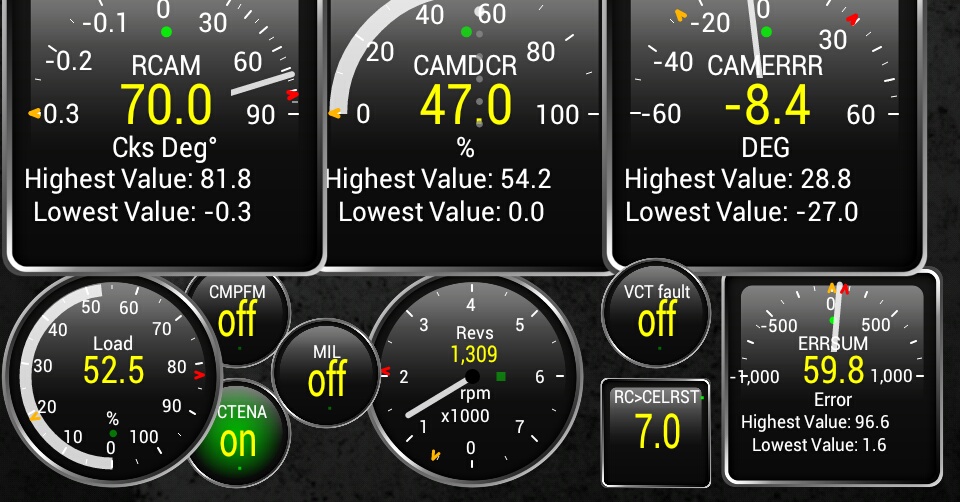

Screenshot taken under conditions almost identical to the freeze frame above - about 90% load and 2350 RPM.

And yes, as you said, Requested Retard (RCAM) and CAMDCR (VCT % duty cycle) declines to zero as load increases. Almost ALL other 'cruising' conditions other than very high RPMs, the PCM is applying some degree of cam retard. Here is an example of cruising around 55 MPH at 50% engine load.

Screenshot of variable cam operation taken under cruising conditions.

I Have researched and 'hacked' the OBDII system extensively, identified these custom Ford 5.4L PIDs and developed custom Torque App gauges to monitor VCT operation. The gauges names are acronyms from Ford's IDS system - except for two. ERRSUM is a 'hair-brained' creation of my own that SUMS every snapshot of CAMERRR, which jumps all around when the PCM changes requested retard (RCAM). This sum of all positive and negative cam error readings tells me if CAMERRR generally trends positive or negative. I 'THINK' a positive equates to "over retard" - but I cannot say with certainty. RC>CELRST is a PID THAT I found that keeps a COUNT of "run cycles" (DIFFERENT FROM drive cycles) since codes were cleared and MIL was reset. The others are self explanatory. [FULL DISCLOSURE] I have never been able to ascertain a proper offset for the RCAM formula. ZERO actually equals ZERO retard applied - the result of ZERO CAMDCR, not actual crankshaft degrees of advance as I would like. See the post at: https://www.f150forum.com/f12/5-4l-p...dvance-300748/ posted in this and two other forums with over 1000 total views in six month - without a single response. Amazing to me that even Livernois (whose solution is to LOCK the phasers at full advance, and even THEY apparently can't tell me how many degrees advance that is). But that's another discussion.

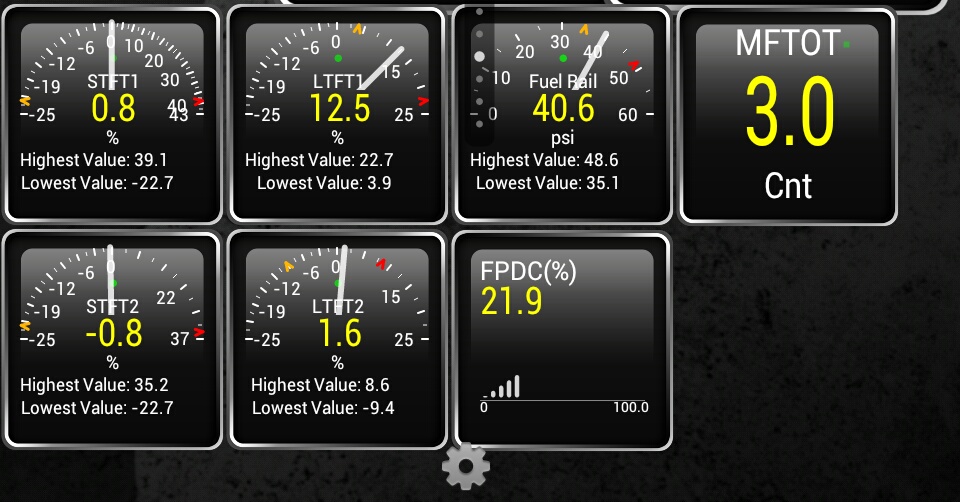

Your comments spurred me to broaden the scope of my investigation to include a closer look at Fuel Trims. I have pretty much "assumed" over retard on bank 2 explained any disparity between bank fuel trims (and that still MAY be true). On a thirty five mile trip this evening, I set up a Torque Pro dashboard with gauges monitor fuel trims and some related parameters. I am experiencing effectively NO misfires - (only 3 in this 35 mile run). Monitoring live data confirms what is shown in the earlier freeze frame. LTFT-1 is generally elevated (+8% to +10%) under ALL driving conditions, increasing proportionately with increased load to (+14-+20%). STFT-1 confirms LTFT-1 as it fluctuates above and below zero under normal driving, increases under load up to (+20%).

I took two screenshots at the conclusion of the trip.

Screenshot of fuel trims at idle at conclusion of 35 mile trip

Screenshot of fuel trims under approx 80% engine load at conclusion of 35 mile trip

As can be seen, fuel trims on Bank 2 are generally nothing to get excited about. I cannot rationalize a vacuum leak for the following reasons: A vacuum leak would effect STFT at idle more than under load because the ratio of un-metered intake air is greater at idle. (Any increase in MAF flow would dramatically reduce un-metered air). With effectively NO misfires, it is difficult to rationalize that is the cause of elevated LTFT-1.

One sluggish or partially clogged injector on bank 1 "WOULD" cause what we are seeing. BUT -- It seems to me that THAT would result in misfires in the TOO lean cylinder or the three over rich cylinders. As can be seen from the O2 graphs in my prior post, fuel trim adjustments are making the O2's perfectly happy, and only 3 misfires in a span of 35 miles seems quiet acceptable to me. I can only rationalize the fuel trims have something to do with differences in cam positioning between bank 1 and bank 2.

ALSO, ONE SIDE NOTE. I noticed this evening, the PCM goes OUT of closed loop pretty easily. With 60-65% load for a distance of 20-30 seconds, it will drop out of closed loop - at which point ALL fuel trims slam to full tilt.

As for the CMCV valve & butterflies! It was replaced when I replaced the IM about 60K miles ago. I recently placed a USB camera (bore scope) back there and VIDEOED the damn thing operating while driving. I learned a bunch about that!! (Totally debunked a whole bunch of my work on Torque Pro gauges for 'live' display of CMCV butterfly positioning. The whole thing is a totally misunderstood hoax. I can tell you that. And NO, the butterflies on bank 1 are opening 90º when the CMCV is activated.

@Especial86, your (and everyone else's) diagnostic thoughts and experiences have been (and are) much appreciated. Even where I may challenge them.

#26

I realize this is an old thread, but I am getting an AER engine this week. After reading especial86's comments about Dorman phasers and VCT, i asked the shop. They said AER uses only Ford parts (at least the phasers and VCTs) effective January 2016.

The following users liked this post:

F150Torqued (05-04-2017)