2.7 Eco Enough Towing?

#21

Originally Posted by jonbar87

TLDR: it takes the same amount of energy (i.e., air/fuel) to make the same amount of horsepower, regardless of the engine size.

This particular engine is capable of producing 1600 kW (about 2145 HP) from ~1360 rpm on up to max engine speed (1800 rpm). Briefly looking at this map across the torque range for this horsepower, you see differences in BSFC from around 198 g/kW-hr to around 211 g/kW-hr. This means that at the 1600kW, this engine can consume anywhere from roughly 99 gallons/hr to 105 gallons/hr.

Without getting into the details as to why, the common trend is that the broader the torque range you have for an engine, the more you can generally optimize efficiency for a given horsepower produced (assuming you have the necessary gearing in a vehicle to take advantage of it). Although I'm by no means an automotive engineer, this is why I feel that the Ecoboost engine could be a superior arrangement to a naturally aspirated V8. I do not have access to the BSFC maps for all of the engines in question, so I suppose I'll never know for sure...

The following users liked this post:

jonbar87 (10-21-2014)

#22

Senior Member

#23

Senior Member

I understand the common term "there is no replacement for displacement". With the 8,500 lbs of towing capacity for the 2.7 Eco, I am debating ordering the 2.7 vs 3.5. I would use the truck primarily for daily commuting (go with 2.7). However if I where to haul a 2 horse trailer (around 5,500 lbs assuming it has 2 horses) with the max towing package on 2 wheel drive XL or XLT should I be concerned?

Not so sure if this chart which was posted in another thread is the official Ford final, but it does have some numbers for towing. Based on this I would suggest you will be fine with the 2.7 EB with the 3.31 rear end, and no need for the max payload package or 3.73 rear end. You really do not gain that much more anyway. (7600 lbs to 8400 lbs in a 4x2)

#24

Senior Member

In theory this is correct, but there are far too many variables in engine design for it to work this way in the real world. Brake Specific Fuel Consumption is an important design characteristic which clearly shows that fuel consumed does not always equal the same amount of horsepower across the board...Although I'm by no means an automotive engineer, this is why I feel that the Ecoboost engine could be a superior arrangement to a naturally aspirated V8. I do not have access to the BSFC maps for all of the engines in question, so I suppose I'll never know for sure...

http://www1.eere.energy.gov/vehicles...ich_2011_o.pdf

#25

Senior Member

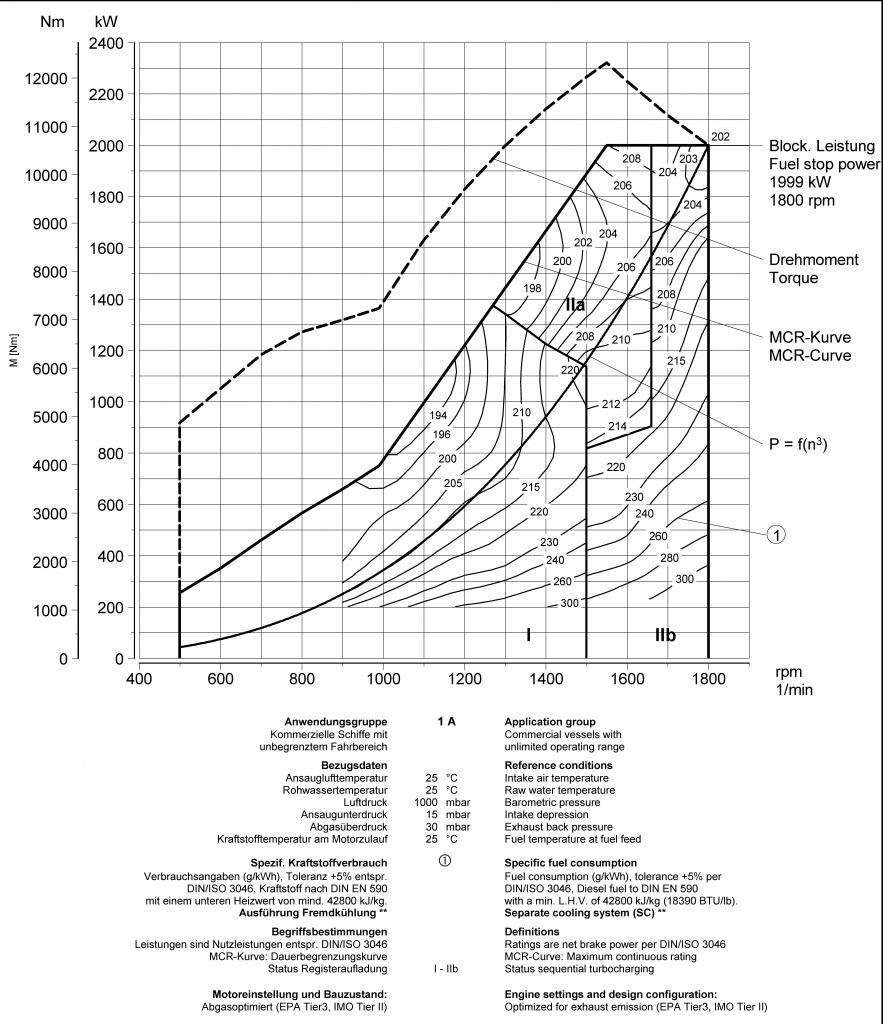

In theory this is correct, but there are far too many variables in engine design for it to work this way in the real world. Brake Specific Fuel Consumption is an important design characteristic which clearly shows that fuel consumed does not always equal the same amount of horsepower across the board. I'm an engineer who works with vessel propulsion system design, and I frequently have to analyze BSFC maps to find areas of peak efficiency for a given engine. Here is an example of a BSFC map for a 1999 kW (2680 HP) diesel engine (BSFC given in g/kW-hr):

This particular engine is capable of producing 1600 kW (about 2145 HP) from ~1360 rpm on up to max engine speed (1800 rpm). Briefly looking at this map across the torque range for this horsepower, you see differences in BSFC from around 198 g/kW-hr to around 211 g/kW-hr. This means that at the 1600kW, this engine can consume anywhere from roughly 99 gallons/hr to 105 gallons/hr.

Without getting into the details as to why, the common trend is that the broader the torque range you have for an engine, the more you can generally optimize efficiency for a given horsepower produced (assuming you have the necessary gearing in a vehicle to take advantage of it). Although I'm by no means an automotive engineer, this is why I feel that the Ecoboost engine could be a superior arrangement to a naturally aspirated V8. I do not have access to the BSFC maps for all of the engines in question, so I suppose I'll never know for sure...

This particular engine is capable of producing 1600 kW (about 2145 HP) from ~1360 rpm on up to max engine speed (1800 rpm). Briefly looking at this map across the torque range for this horsepower, you see differences in BSFC from around 198 g/kW-hr to around 211 g/kW-hr. This means that at the 1600kW, this engine can consume anywhere from roughly 99 gallons/hr to 105 gallons/hr.

Without getting into the details as to why, the common trend is that the broader the torque range you have for an engine, the more you can generally optimize efficiency for a given horsepower produced (assuming you have the necessary gearing in a vehicle to take advantage of it). Although I'm by no means an automotive engineer, this is why I feel that the Ecoboost engine could be a superior arrangement to a naturally aspirated V8. I do not have access to the BSFC maps for all of the engines in question, so I suppose I'll never know for sure...

Last edited by jonbar87; 10-21-2014 at 12:46 PM.

#26

You can find some more applicable BSFC charts for the EcoBoost engine design at the link below. See slides starting on page 22. The short story is that the maximum efficiency island is made bigger and pushed lower in RPM and higher in torque with the use of the turbos and direct injection.

http://www1.eere.energy.gov/vehicles...ich_2011_o.pdf

http://www1.eere.energy.gov/vehicles...ich_2011_o.pdf

#27

I understand this, which is why I said "Assuming the VE (volumetric efficiency) of the engines and other variables (e.g., weight, gearing, compression ratios, etc.) are the same." VE plays a key role in determining engine efficiency, which usually has to do with intake and head design, as well as valve flow.

The bottom line is that the technology utilized in the Ecoboost will allow for greater efficiency over a broader HP range than a typical NA V8 would. I'm sold on the technology from a performance standpoint; my bigger concerns are now with reliability and durability.

The bottom line is that the technology utilized in the Ecoboost will allow for greater efficiency over a broader HP range than a typical NA V8 would. I'm sold on the technology from a performance standpoint; my bigger concerns are now with reliability and durability.

The following users liked this post:

jonbar87 (10-21-2014)

#28

Senior Member

My thoughts are exactly the same. The performance is there and is ideal for towing. The problem is in the complications of the technology which clearly are fuel dilution of the lubricating oil, and the effect that has on engine durability. And also of significant but lesser concern is the charge air cooler condensation and what slugs of water do to the engine/spark plugs/turbo, as well as the coking of the intake valves due to direct injection.

#29

Senior Member

you know that to make x horsepower, you need x size fuel pulse (measured in ms) to compensate for x amount air (whether it's coming from 7.0 liters of N/A displacement, or a 2.7 Liter engine with a turbo).The reason for the turbo is to be energy saving when the engine is NOT required to make all that extra power; it does NOT save energy when towing, it's actually what's forcing more air into the engine, causing the injectors open for a longer period of time and makeup the extra horsepower for the lack of displacement, thus ultimately using more fuel (or the same as a large displacement engine).

the 2.7 isn't wasting so much fuel while cruising because it doesn't have all that displacement. However, just say both the 7.0 and 2.7 were both 325 HP and needed to operate at WOT to tow 10,000lbs up a hill, if both engines were at peak HP @ whatever RPM they make peak HP at, they would both use the EXACT same amount of fuel. Period.

the 2.7 isn't wasting so much fuel while cruising because it doesn't have all that displacement. However, just say both the 7.0 and 2.7 were both 325 HP and needed to operate at WOT to tow 10,000lbs up a hill, if both engines were at peak HP @ whatever RPM they make peak HP at, they would both use the EXACT same amount of fuel. Period.

Basically a non-forced induction engine is a fixed displacement engine. Which means while you can make it easier for air to flow, you are not pushing more air into the system. A forced induction engine (turbo, procharger, supercharger) is like a variable displacement engine. That does not mean that the engine changes it's size, just that it has the capability to perform the same as a bigger NA motor.

Displacement is a measure of volume. Forced induction pumps air into the engine, thus increasing the volume of the air for more power/torque. If you pump the same volume of air into a cylinder and add the appropriate amount of fuel, you are using the same amount of energy as a bigger displacement naturally aspirated engine. When running highway speeds at low RPM's you do not need this. That's why forced induction systems appear to have better gas mileage when unloaded on the highway. They are performing as they were designed.

I'm sure I'll get some people blowing up telling me how wrong I am. I don't care. I'm tired of the blind chest thumping about these motors. People need to understand some of the science behind them.

EDIT** I posted this before getting to page 3 and looking at posts by KP Texan and Ron AKA. I'm sure they have more knowledge. The above is how it was explained to me for military diesels years ago, before turbos were as popular on american vehicles. To me it makes perfect sense, but I'm an odd duck so I've been told. Lol.

Last edited by Manuellabour247; 10-21-2014 at 04:38 PM.

The following 2 users liked this post by Manuellabour247:

isthatahemi (10-22-2014),

jonbar87 (10-21-2014)

#30

Senior Member

My thoughts are exactly the same. The performance is there and is ideal for towing. The problem is in the complications of the technology which clearly are fuel dilution of the lubricating oil, and the effect that has on engine durability. And also of significant but lesser concern is the charge air cooler condensation and what slugs of water do to the engine/spark plugs/turbo, as well as the coking of the intake valves due to direct injection.

I hate to break it to you...but a good engineer would have seen this and decided it's not really a wide spread problem...