Removing coolant temp sensor on 91 4.9

#1

Senior Member

Thread Starter

Join Date: Sep 2008

Location: San Diego

Posts: 206

Likes: 0

Received 0 Likes

on

0 Posts

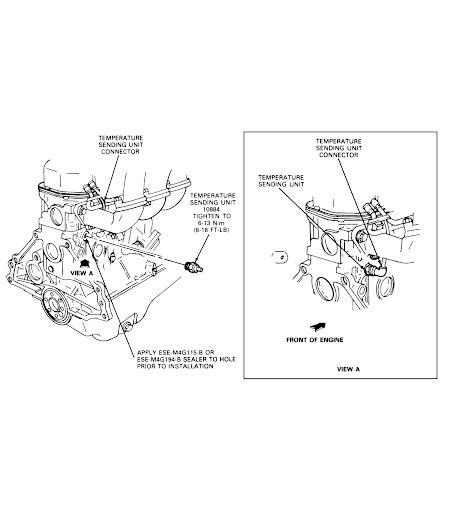

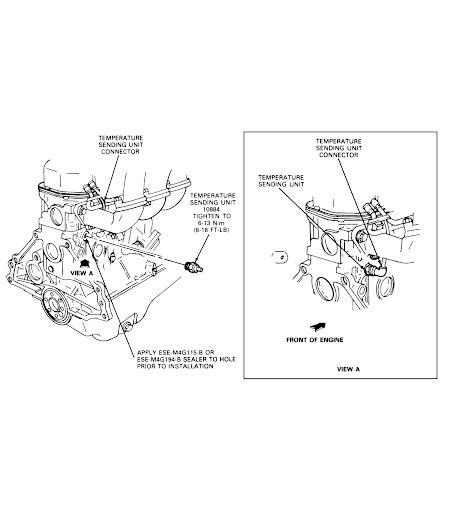

Trying to remove the coolant temperature sensor on my truck. It's at a pretty awkward angle. Any tips on removing it? Anyone know what size wrench I should use?

If I can get the sensor wire off I might be able to get a socket on it. I tried pulling the connector off of it but it didn't come off. It spins a little but I don't want to pull too hard and damage it. Should it come straight off the same way a spark plug wire comes off of a plug, or is it threaded on?

If I can get the sensor wire off I might be able to get a socket on it. I tried pulling the connector off of it but it didn't come off. It spins a little but I don't want to pull too hard and damage it. Should it come straight off the same way a spark plug wire comes off of a plug, or is it threaded on?

#4

Senior Member

Thread Starter

Join Date: Sep 2008

Location: San Diego

Posts: 206

Likes: 0

Received 0 Likes

on

0 Posts

The wire was sort of rusted to the pole of the sending unit. A little PB oil and some plyers made it easy enough.

Since I replaced the sensor, the temperature gauge hasn't worked though...

Since I replaced the sensor, the temperature gauge hasn't worked though...

#5

Turn the key on and have the sensor unplugged. The needle should be all the way to one side of the gauge. Then ground the sensor wire, the needle should go all the way to the other side of the gauge. If this doesn't happen then check for a broken sensor wire, a bad gauge or no power to the gauge.

#6

Senior Member

Thread Starter

Join Date: Sep 2008

Location: San Diego

Posts: 206

Likes: 0

Received 0 Likes

on

0 Posts

Awesome!..sort of....The gauge was already all the way to the left after reconnecting everything. Removing the wire or grounding it didn't have any effect on the needle. Since everything worked before I changed the sensor and the wire was really brittle to begin with, I'm assuming it's rotted out (or I broke it when I took it off) and is my problem.

I'll start tracing down the corroded/bad sections of wire. Any idea how to tell when I've moved far enough along and found a good (functioning) piece of wire? Will there be a voltage running to it?

I'll start tracing down the corroded/bad sections of wire. Any idea how to tell when I've moved far enough along and found a good (functioning) piece of wire? Will there be a voltage running to it?

#7

No voltage to that wire, it supplies varying amounts of ground to the gauge to change the needle position. You can check for continuity from the wire end at the sensor to anywhere further down the wire. When you no longer have continuity, you have found where the break is. In case you don't know, testing for continuity just tells you the wire can send the signal it sends, be it ground or power. You need a self powered voltmeter to test continuity.

Trending Topics

#9

Senior Member

Thread Starter

Join Date: Sep 2008

Location: San Diego

Posts: 206

Likes: 0

Received 0 Likes

on

0 Posts

Update:

Wire was corroded/frayed just behind the connector. Removed the bad wire; back in business now. While I was doing the coolant system work I replaced the radiator cap - old one was leaking.

Now that everything is connected and buttoned up, something is causing the truck to overheat though. When it starts, it warms up at the normal rate, but then quickly climbs toward overheating. If I'm on the highway it won't get too hot - but still hotter than normal. Low speed driving requires stopping after about 15 minutes or so.

Does this sound like a thermostat sticking?

Wire was corroded/frayed just behind the connector. Removed the bad wire; back in business now. While I was doing the coolant system work I replaced the radiator cap - old one was leaking.

Now that everything is connected and buttoned up, something is causing the truck to overheat though. When it starts, it warms up at the normal rate, but then quickly climbs toward overheating. If I'm on the highway it won't get too hot - but still hotter than normal. Low speed driving requires stopping after about 15 minutes or so.

Does this sound like a thermostat sticking?

#10

Senior Member

Join Date: Oct 2008

Location: Powder Springs, GA

Posts: 385

Likes: 0

Received 0 Likes

on

0 Posts

Sounds like a thermostat stickin, yeah. And also, what PSI radiator cap did you get? Mines a 15. and has a release lever on it. from autozone. It helped out with that. but I also replaced my thermostat 5 TIMES!